5 Installation and Commissioning

5.6 Encoder and Sync Switch Installation

90 3HNA009834-001 en Rev.06 Product Manual, Control Cabinet IRC5P

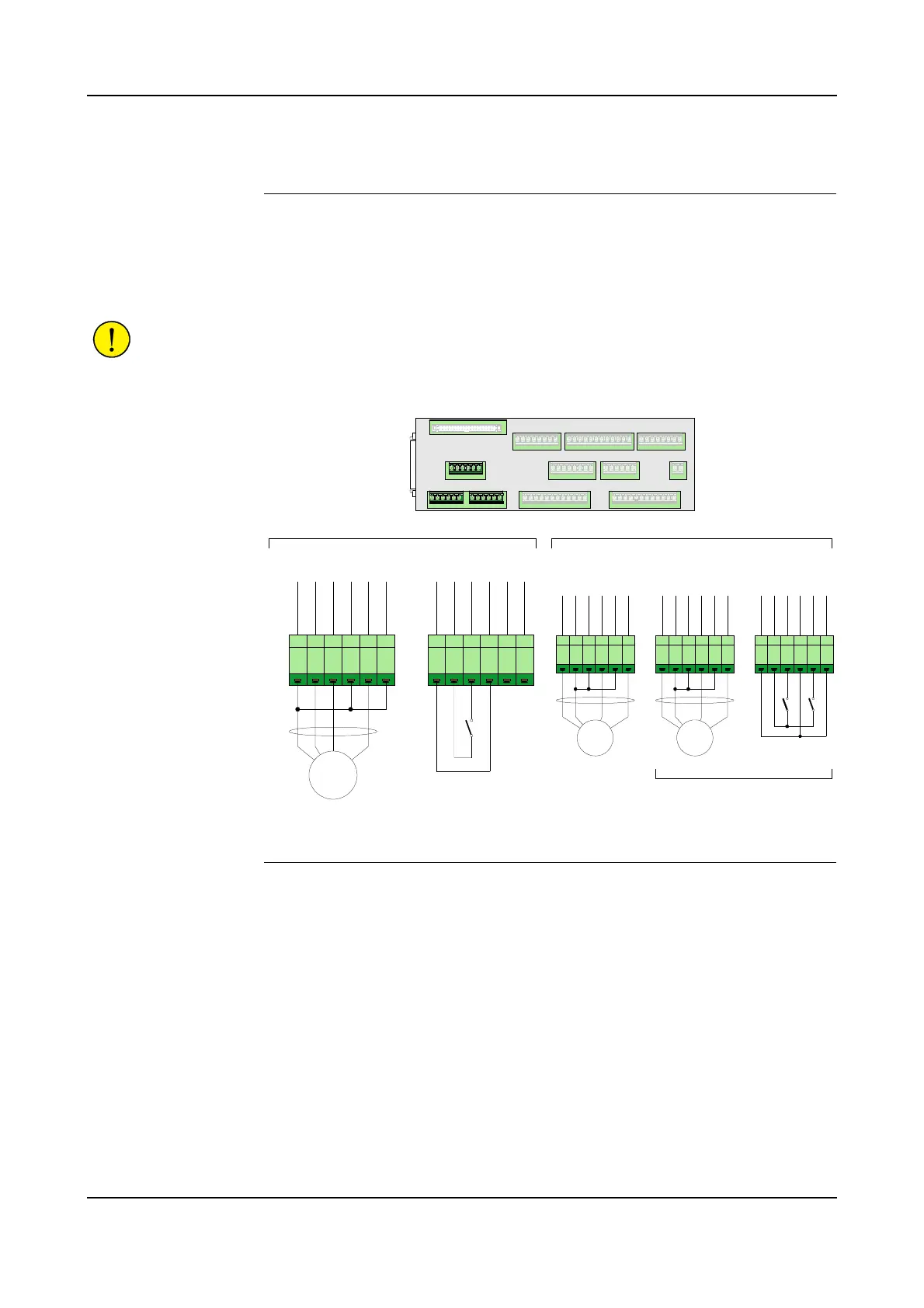

5.6.4 Connection Overview

Connector Description The illustration below shows the connections for 1, 2 or 3 encoders and sync switch.

Connections are made on the Safety Connection Board, SCB.

Connections for conveyor tracking will normally consist of one PNP encoder

connected to connector X5 and one sync switch connected to connector X7.

CAUTION! To avoid interference to encoder signals, 4 wire twisted pair screened

cables must be used for encoder connections.

Figure 38 Encoder and Sync Switch connection

Options The encoder inputs support both PNP and NPN type encoders. Optionally an NPN

encoder can be installed. Optionally connector X7 may be used for a third encoder

or for connection of a second sync switch, as shown in the illustration.

The optional components must be configured explicitly.

Note: The system supports 24VDC encoders. If RS422 encoders are used, a signal

converter such as BLE-01 must be used.

Extra encoders can be used for a second conveyor, a backup encoder, or for

monitoring of paint flow e.g. when using Küppers initiators. For more information

on monitoring paint flow, refer to the gear flow meter in the ‘Unit Description,

Paint’ manual.

X5 X6 X2 X1

X3 X13 X4

X8 X9 X10

X11

X12

X7

SCB-01

1 2 3 4 5 6

+

2

4

V

D

C

G

N

D

E

N

C

_

1

A

+

E

N

C

_

1

A

-

E

N

C

_

1

B

+

E

N

C

_

1

B

-

PNP

Encoder 1

X5

1 2 3 4 5 6

+

2

4

V

D

C

G

N

D

P

_

S

T

A

R

T

_

0

1

+

P

_

S

T

A

R

T

_

0

1

-

P

_

S

T

A

R

T

_

0

2

+

P

_

S

T

A

R

T

_

0

2

-

Sync Switch 1

X7

1 2 3 4 5 6

+

2

4

V

D

C

G

N

D

E

N

C

_

2

A

+

E

N

C

_

2

A

-

E

N

C

_

2

B

+

E

N

C

_

2

B

-

1 2 3 4 5 6

+

2

4

V

D

C

G

N

D

E

N

C

_

3

A

+

E

N

C

_

3

A

-

E

N

C

_

3

B

+

E

N

C

_

3

B

-

Encoder 3

X6 X7

NPN

1 2 3 4 5 6

+

2

4

V

D

C

G

N

D

P

_

S

T

A

R

T

_

0

1

+

P

_

S

T

A

R

T

_

0

1

-

P

_

S

T

A

R

T

_

0

2

+

P

_

S

T

A

R

T

_

0

2

-

Sync Switch 1

X7

Sync Switch 2

Encoder 3 or

Sync Switch(es) connection

Encoder 2

NPN

OptionsStandard conveyor connections

Loading...

Loading...