Rockwell Automation Publication 750-IN001O-EN-P - October 2014 147

Power Wiring Chapter 4

Power Cable Types

Acceptable for 200…600

Volt Installations

For detailed information on a variety of cable types that are acceptable for drive

installations, refer to Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drive, publication DRIVES-IN001

.

Wire Recommendations

Motor Considerations

Due to the operational characteristics of AC variable frequency drives, motors

with inverter grade insulation systems designed to meet or exceed NEMA MG1

Part 31.40.4.2 standards for resistance to spikes of 1600 volts are recommended.

Guidelines must be followed when using non-inverter grade motors to avoid

premature motor failures. Refer to Wiring and Grounding Guidelines for Pulse

Width Modulated (PWM) AC Drives, publication DRIVES-IN001

for

recommendations.

Terminal Block Specifications

Table 7 - Wall Mount Frames 1…5 Power Terminal Block

ATTENTION: National Codes and standards (NEC, BSI and so forth) and local

codes outline provisions for safely installing electrical equipment. Installation

must comply with specifications regarding wire types, conductor sizes, branch

circuit protection and disconnect devices. Failure to do so may result in personal

injury and/or equipment damage.

Type Description Min. Insulation Rating

Power

(1)(2)

(1) Control and signal wires should be separated from power wires by at least 0.3 meters (1 foot).

(2) The use of shielded wire for AC input power may not be necessary but is always recommended.

Standard • Four tinned copper conductors with XLPE

insulation.

• Copper braid/aluminum foil combination

shield and tinned copper drain wire.

• PVC jacket.

600V,

75 °C (167 °F)

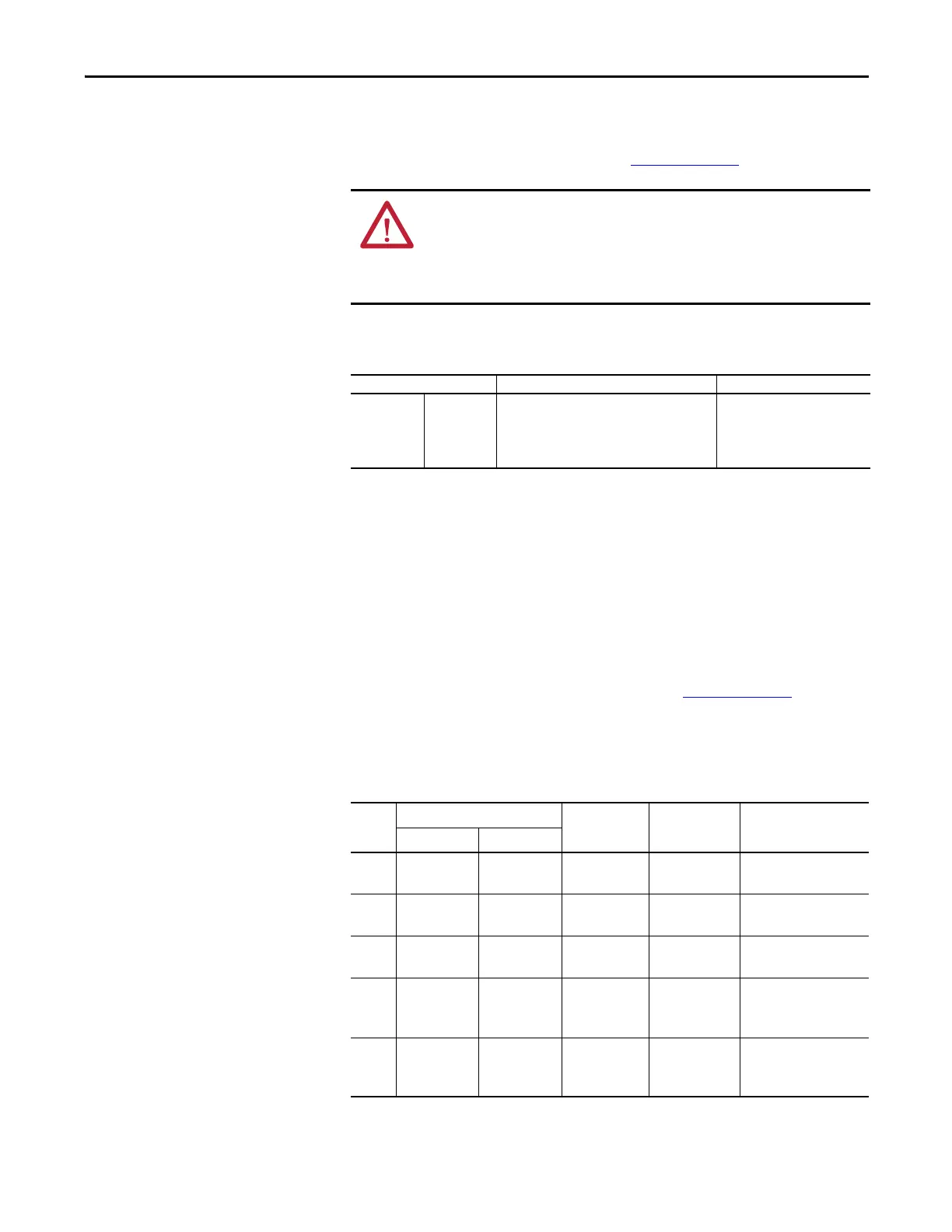

Frame Wire Size Range

(1)

(2)

(1) Maximum/minimum wire sizes that the terminal block will accept - these are not recommendations.

(2) Terminal blocks are designed to accept a single wire.

Strip Length Recommended

Torque

Recommended Tool(s)

Maximum Minimum

14.0 mm

2

(10 AWG)

0.2 mm

2

(24 AWG)

8.0 mm

(0.31 in.)

0.57 N•m

(5 lb•in)

#2 Pozidrive®, M3 x 7

24.0 mm

2

(10 AWG)

0.2 mm

2

(24 AWG)

8.0 mm

(0.31 in.)

0.57 N•m

(5 lb•in)

#2 Pozidrive®, M3 x 7

3 16.0 mm

2

(6 AWG)

0.5 mm

2

(20 AWG)

10.0 mm

(0.39 in.)

1.2 N•m

(10.6 lb•in)

#2 Flat Screwdriver

4 25.0 mm

2

(3 AWG)

2.5 mm

2

(14 AWG)

10.0 mm

(0.39 in.)

2.7 N•m

(24 lb•in)

#2 Pozidrive®

492-C Phillips®

0.25 in. Flat Screwdriver

5 35.0 mm

2

(1 AWG)

10.0 mm

2

(8 AWG)

12.0 mm

(0.5 in.)

4.0 N•m

(35 lb•in)

#2 Pozidrive®

492-C Phillips®

0.25 in. Flat Screwdriver

Loading...

Loading...