262 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Chapter 5 I/O Wiring

Safe Torque Off Option

Module

The safe torque off option is just one component in a safety control system.

Components in the system must be chosen and applied appropriately to achieve

the desired level of operational safety. For detailed information on applying this

option, refer to the PowerFlex 750-Series Safe Torque Off User Manual,

publication 750-UM002

.

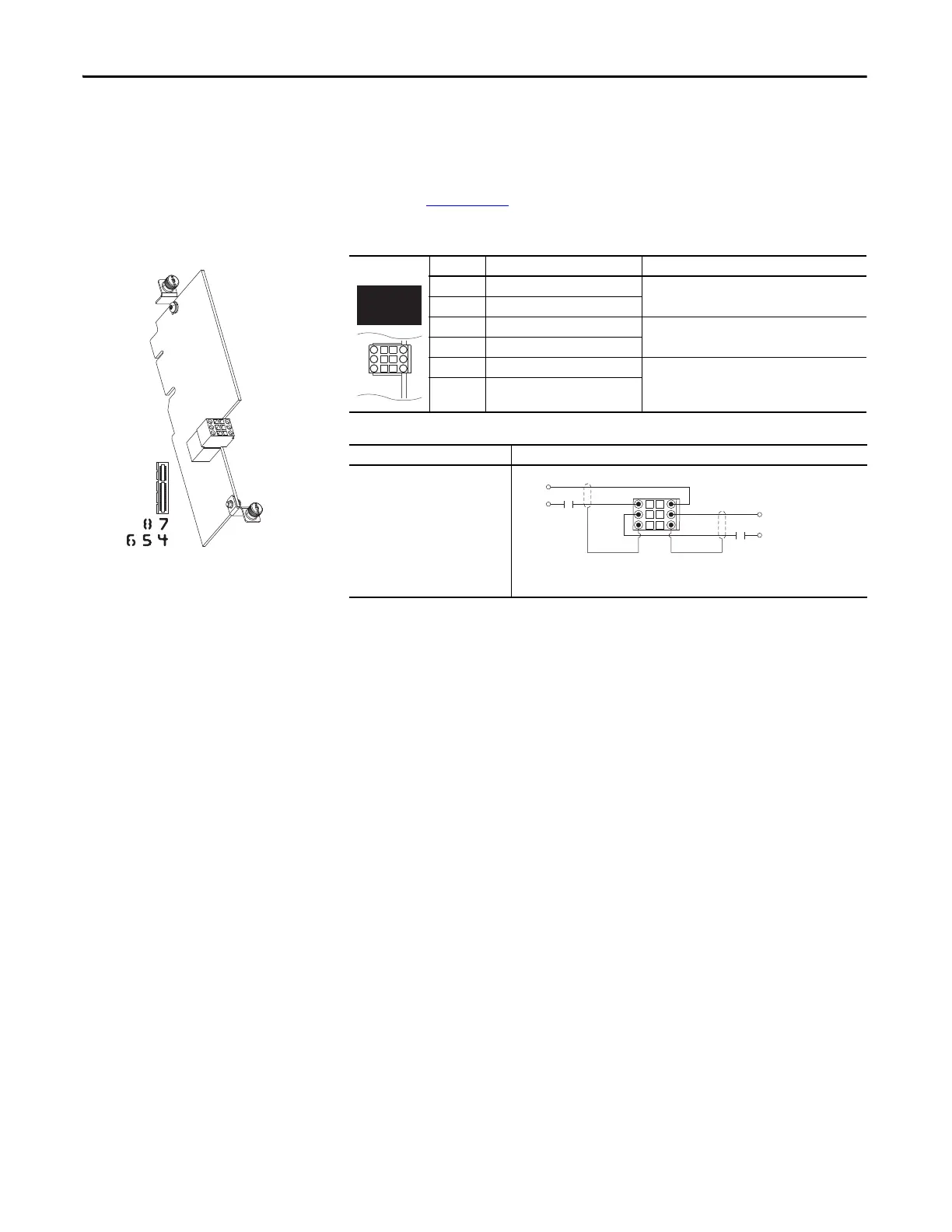

Table 63 - TB2 Terminal Designations

Important Safe Torque Off Option Module Installation Notes

Cabling

• Safety input wiring must be protected against external damage by cable

ducting, conduit, armored cable or other means.

• Shielded cable is required.

Power Supply Requirements

• The external power supply must conform to the Directive 2006/95/EC

Low Voltage, by applying the requirements of EN61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests and one of the

following:

– EN60950 - SELV (Safety Extra Low Voltage)

– EN60204 - PELV (Protective Extra Low Voltage)

– IEC 60536 Safety Class III (SELV or PELV)

– UL 508 Limited Voltage Circuit

– 24V DC ±10% must be supplied by a power supply that complies with

– IEC/EN60204 and IEC/EN 61558-1.

• For planning information, refer to the guidelines in Industrial Automation

Wiring and Grounding Guidelines, publication 1770-4.1.

Terminal Name Description

SP+ +24 Volt Safety Power User-supplied power: 24 volt ±10%

45 mA typical

SP- Safety Power Common

SE+ +24 Volt Safety Enable User-supplied power: 24 volt ±10%

25 mA typical

SE- Safety Enable Common

Sd Shield Terminating point for wire shields when an EMC

plate or conduit box is not installed.

Sd Shield

Safety Input Connection Example

Power Supply

Important: Only break the 24V DC user-supplied power feeding the option

module. Do not remove the line voltage from the 24V DC power supply.

SP+

SE+

Sd

SP-

SE-

Sd

SE-

SP+

SP-

SE+

Sd Sd

Common

+24V

+24V

Common

Loading...

Loading...