Introduction to the diagnostic system

Multi axis servo system - AX800010

Version: 1.1

2 Introduction to the diagnostic system

2.1 Basic knowledge of the diagnostic system

Control in the AX8000 is monitored by the device itself. Diagnostic messages are generated if an error

occurs in the control process or in the parameterization. In case of an error, all previous diagnostic

messages should be examined in addition to the latest message. All diagnostic messages are displayed in

the TwinCAT Drive Manager 2 and in the System Manager.

Background information: Layout of the firmware structure

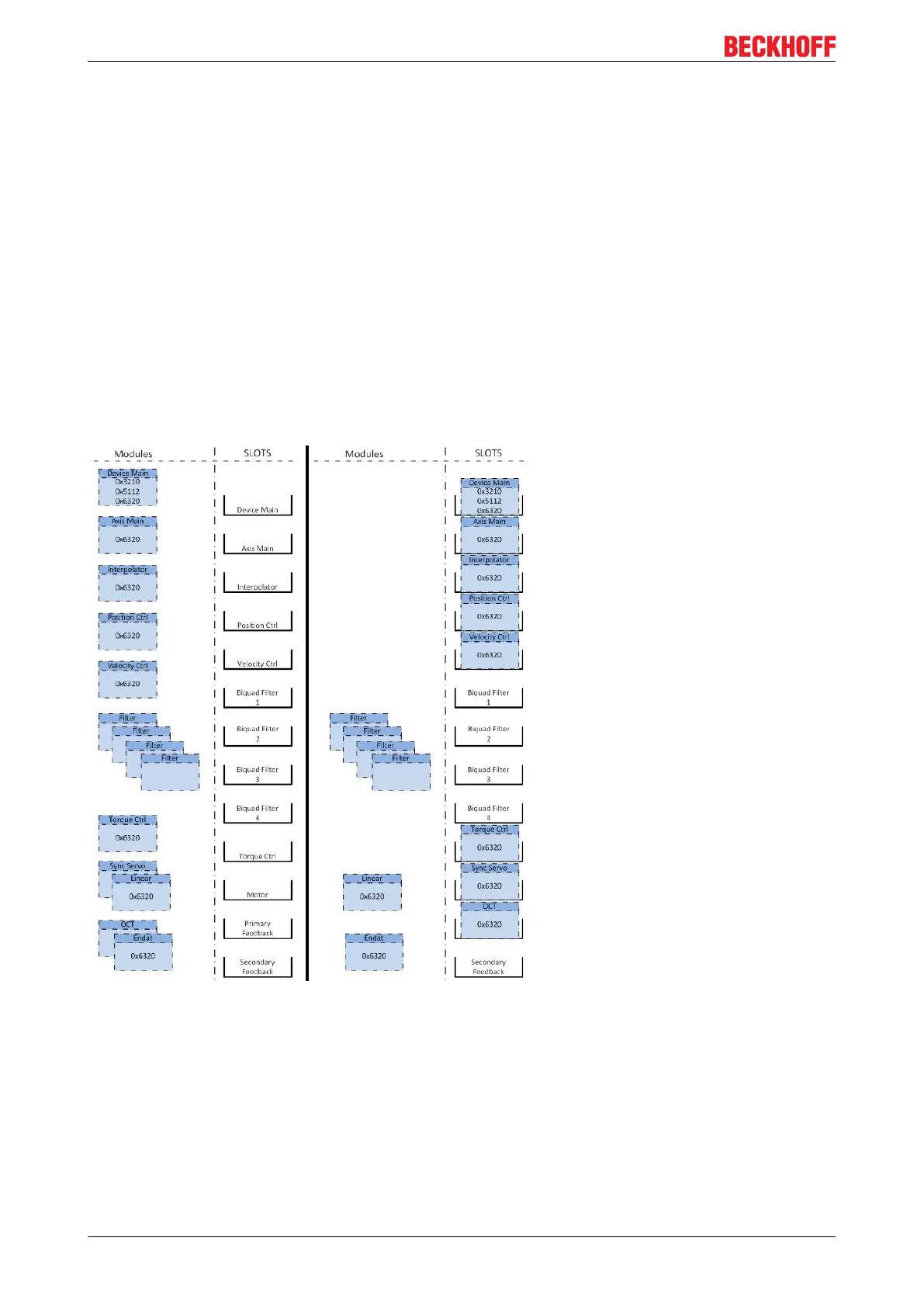

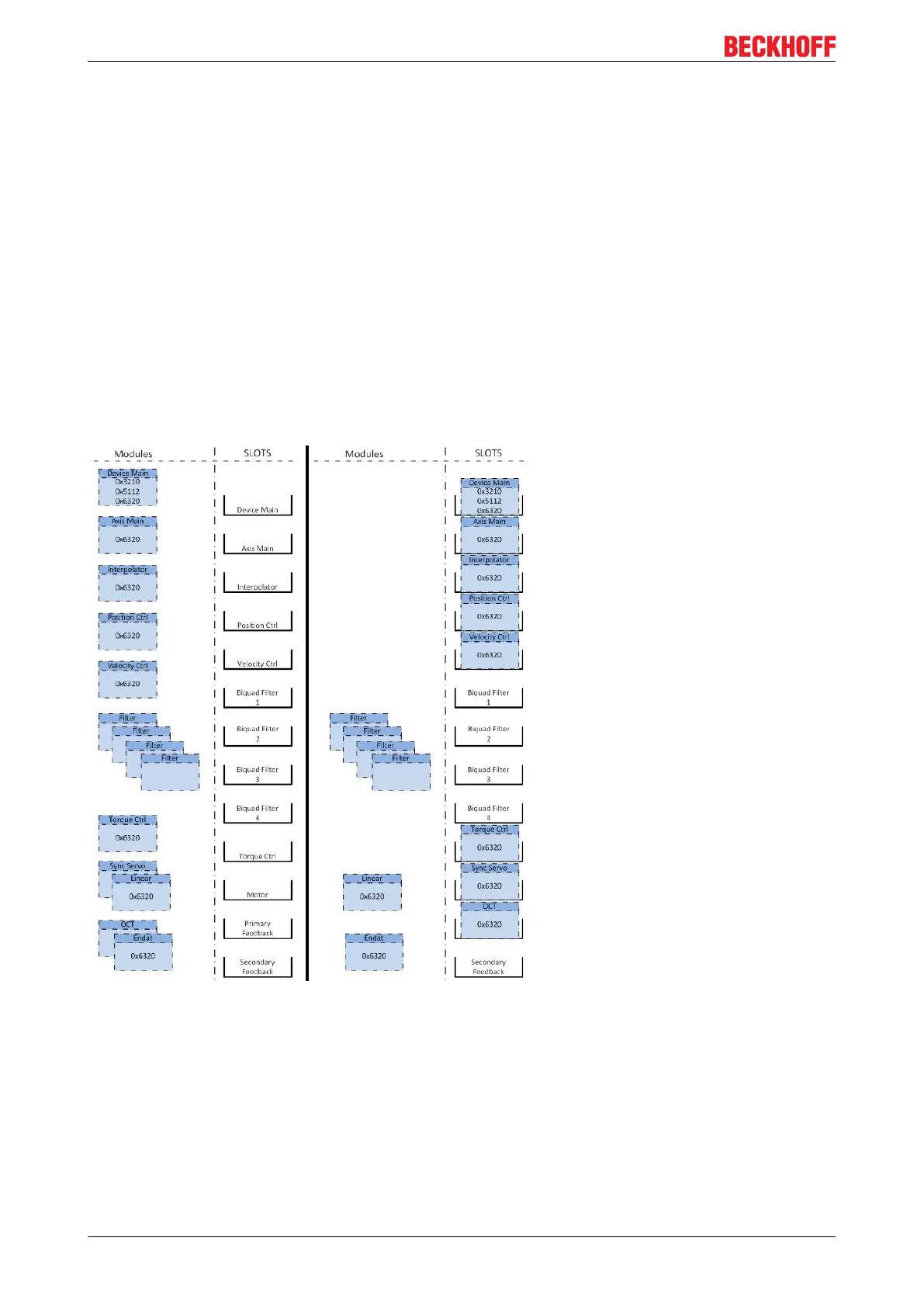

The AX8000 has various slots that can be combined with a module. A module is assigned automatically to

each slot by TwinCAT Drive Manager 2, irrespective of the configuration. The modules are already contained

in the firmware of the AX8000.

A module is mandatory for some slots. In other cases the slot is always occupied by the same module,

because only one module is available (see Device Main or Axis Main, for example). Otherwise the TC Drive

Manager 2 chooses between the modules, e.g. sync servo module and linear module for the motor slot.

Fig.1: Modules and slots - basic knowledge

A module becomes effective and can send diagnostic messages as soon as it is assigned to a slot.

However, the different modules can issue the same diagnostic messages. In order for the cause of each

message to be identified and remedied, it is important to know the origin of the diagnostic message.

Therefore, in addition to the diagnostic message itself, the module that issued it needs to be known.

A module is made up of several CoE objects that contain further subindices (number after the colon). Each

subindex has a pool of parameter objects.

Loading...

Loading...