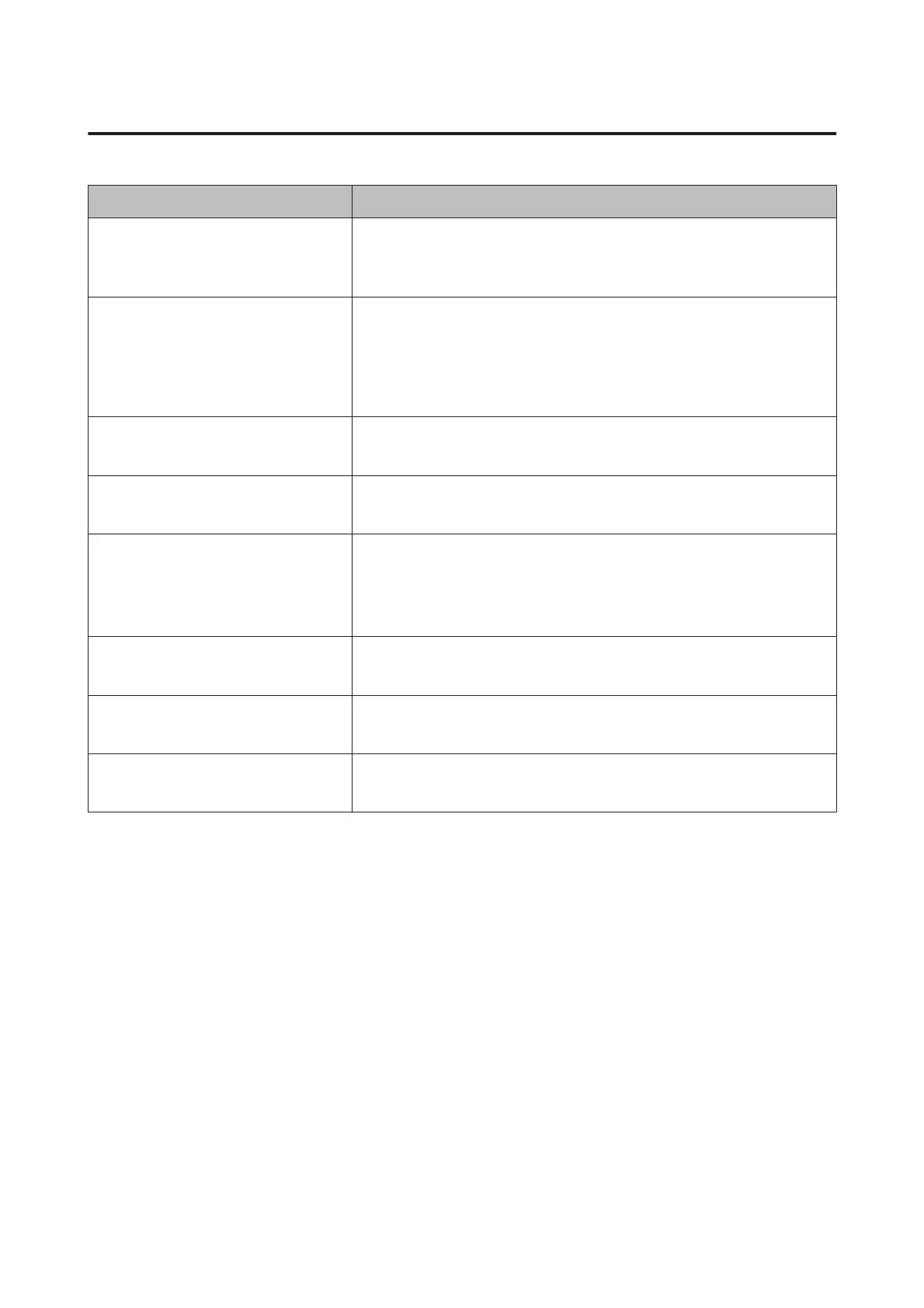

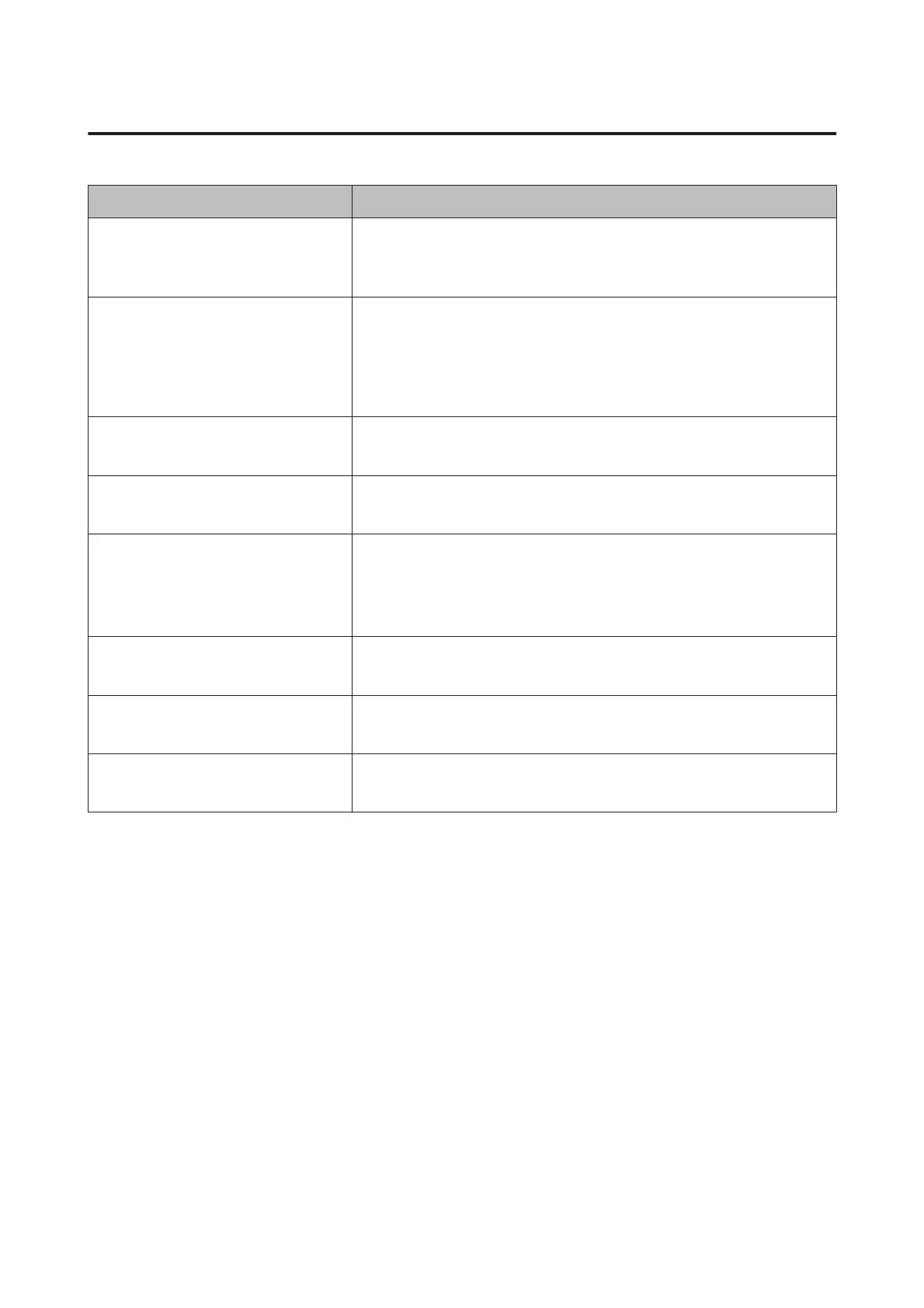

Other maintenance

When to perform Operation

❏ Once every three weeks

❏ Before starting operations for the

day (WH/MS only)

*

Shaking ink cartridges

U “Shaking” on page 66

❏ When checking if nozzles are clogged

❏ When checking which colors are

clogged

❏ Horizontal stripes or tint unevenness

(banding) are appeared.

Checking for clogged nozzles

U “Checking for clogged nozzles” on page 76

When a clog is found after checking for

clogged nozzles

Head Cleaning

U “Head Cleaning” on page 77

When the printer will not be used for an

extended period (and switched off)

Pre-Storage Maint.

U “Long-term Storage (Pre-storage Maintenance)” on page 79

(SC-S80600 Series only)

❏ When changing the spot color to

use (WH <= => MS)

❏ 10 color mode <= => 9 color mode

Change Color Mode

U “Change Color Mode (SC-S80600 Series only)” on page 80

When dirt from rollers adheres to print

outs

Pressure rollers

U “Cleaning pressure rollers” on page 82

When it is hard to see inside the printer Inside the front cover

U “Cleaning inside the front cover” on page 82

When a greasing message is displayed on

the control panel

Applying the supplied grease to the carriage rod

U “Applying Grease to the Carriage Rod” on page 83

* In SC-S80600 Series when 10 color mode selected

SC-S80600 Series/SC-S60600 Series/SC-S40600 Series User's Guide

Maintenance

57

Loading...

Loading...