9.4.2 USE OF CHECK SYNC 2 AND SYSTEM SPLIT

Check Sync 2 (CS2) and System Split functions are included for situations where the maximum permitted slip

fr

equency and phase angle for synchr

onism checks can change due to adverse system conditions. A typical

application is on a closely interconnected system, where synchronism is normally retained when a feeder is

tripped. But under some circumstances, with parallel interconnections out of service, the feeder ends can drift out

of synchronism when the feeder is tripped. Depending on the system and machine characteristics, the conditions

for safe circuit breaker closing could be, for example:

Condition 1: For synchronized systems, with zero or very small slip:

● Slip <50 mHz; phase angle <30°

Condition 2: For unsynchronized systems, with significant slip:

● Slip < 250 mHz; phase angle <10° and decreasing

By enabling both CS1 and CS2, the device can be configured to allow CB closure if either of the two conditions is

detected.

For manual circuit breaker closing with synchronism check, some utilities might prefer to arrange the logic to

check initially for condition 1 only. However, if a System Split is detected before the condition 1 parameters are

satisfied, the device will switch to checking for condition 2 parameters instead, based on the assumption that a

significant degree of slip must be present when system split conditions are detected. This can be arranged by

suitable PSL logic, using the System Check DDB signals.

9.4.3 PREDICTIVE CLOSURE OF CIRCUIT BREAKER

The setting CS2 Slip Contr

ol

setting contains an option (freq + CB comp) for compensating the time taken to close

the CB. When set to provide CB Close Time compensation, a predictive approach is used to close the circuit

breaker ensuring that closing occurs at close to 0º therefore minimising the impact to the power system. The

actual closing angle is subject to the constraints of the existing product architecture, i.e. the protection task runs

twice per power system cycle, based on frequency tracking over the frequency range of 40 Hz to 70 Hz.

9.4.4 VOLTAGE AND PHASE ANGLE CORRECTION

For the Check Synchronisation function, the device needs to convert measured secondary voltages into primary

v

oltages. In some applications, V

Ts either side of the circuit breaker may have different VT Ratios. In such cases, a

magnitude correction factor is required.

There are some applications where the main VT is on the HV side of a transformer and the Check Sync VT is on the

LV side, or vice-versa. If the vector group of the transformer is not "0", the voltages are not in phase, so phase

correction is also necessary.

The correction factors are as follows and are located in the CT AND VT RATIOS column:

● C/S V kSM, where kSM is the voltage correction factor.

● C/S Phase kSA, where kSA is the angle correction factor.

Assuming C/S input setting is A-N, then:

The line and bus voltage magnitudes are matched if V

a sec

= V

cs sec

x C/S V kSA

The line and bus voltage angles are matched if ÐV

a sec

= ÐV

cs sec

+ C/S Phase kSA

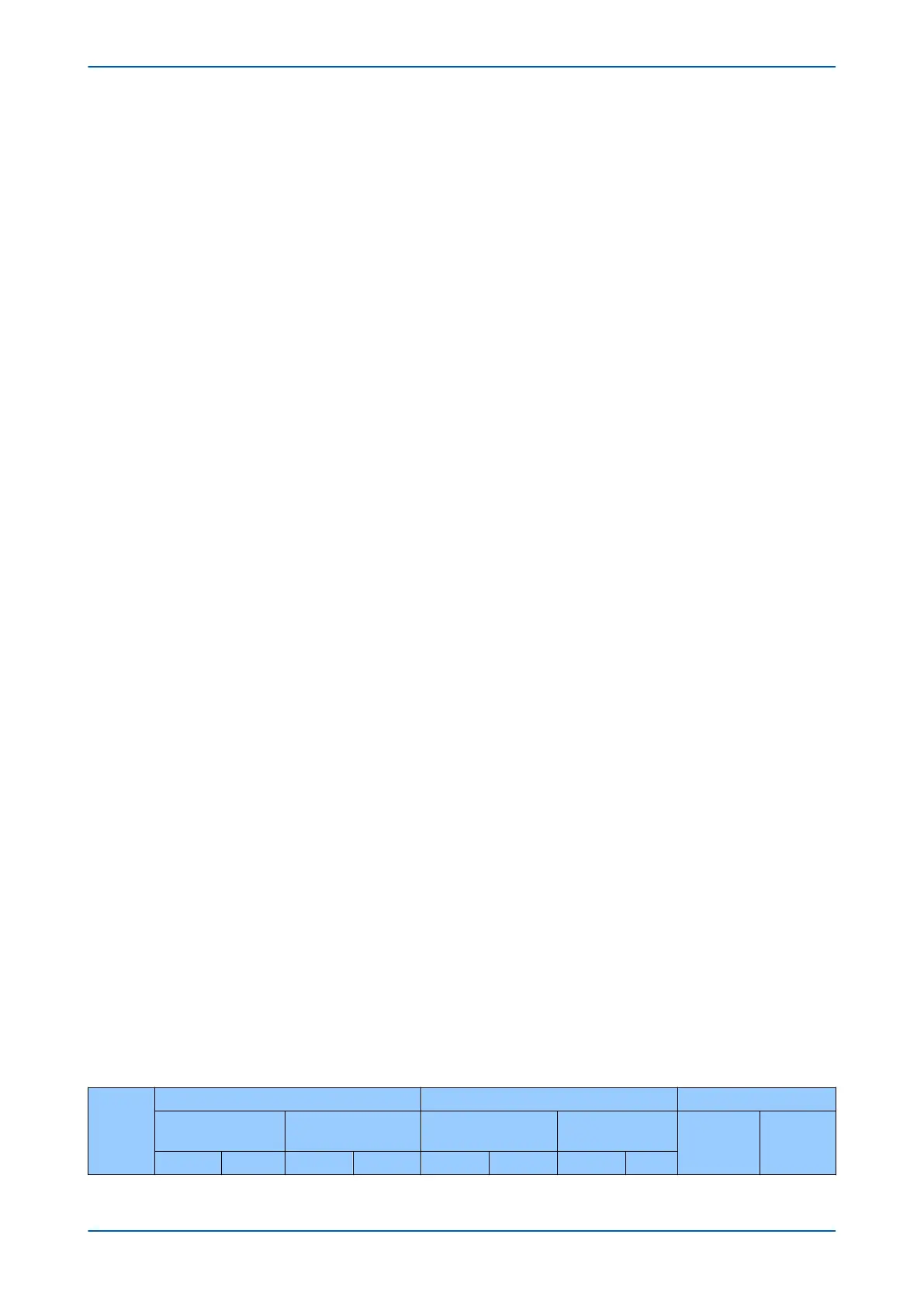

The following application scenarios show where the voltage and angular correction factors are applied to match

different VT ratios:

Scenario

Physical Ratios (ph-N Values) Setting Ratios CS Correction Factors

Main VT Ratio CS VT Ratio

Main VT Ratio (ph-

ph) Alw

ays

CS V

T Ratio

kSM kSA

Pri (kV) Sec (V) Pri (kV) Sec (V) Pri (kV) Sec (V) Pri (kV) Sec (V)

P14x Chapter 14 - Monitoring and Control

P14xEd1-TM-EN-1 335

Loading...

Loading...