HEIDENHAIN TNC 426, TNC 430 291

8.6 SL cycles

REAMING (Cycle 21)

Process

Same as Cycle 1, Pecking; see “Cycles for Drilling, Tapping and Thread

Milling,” page 209.

Application

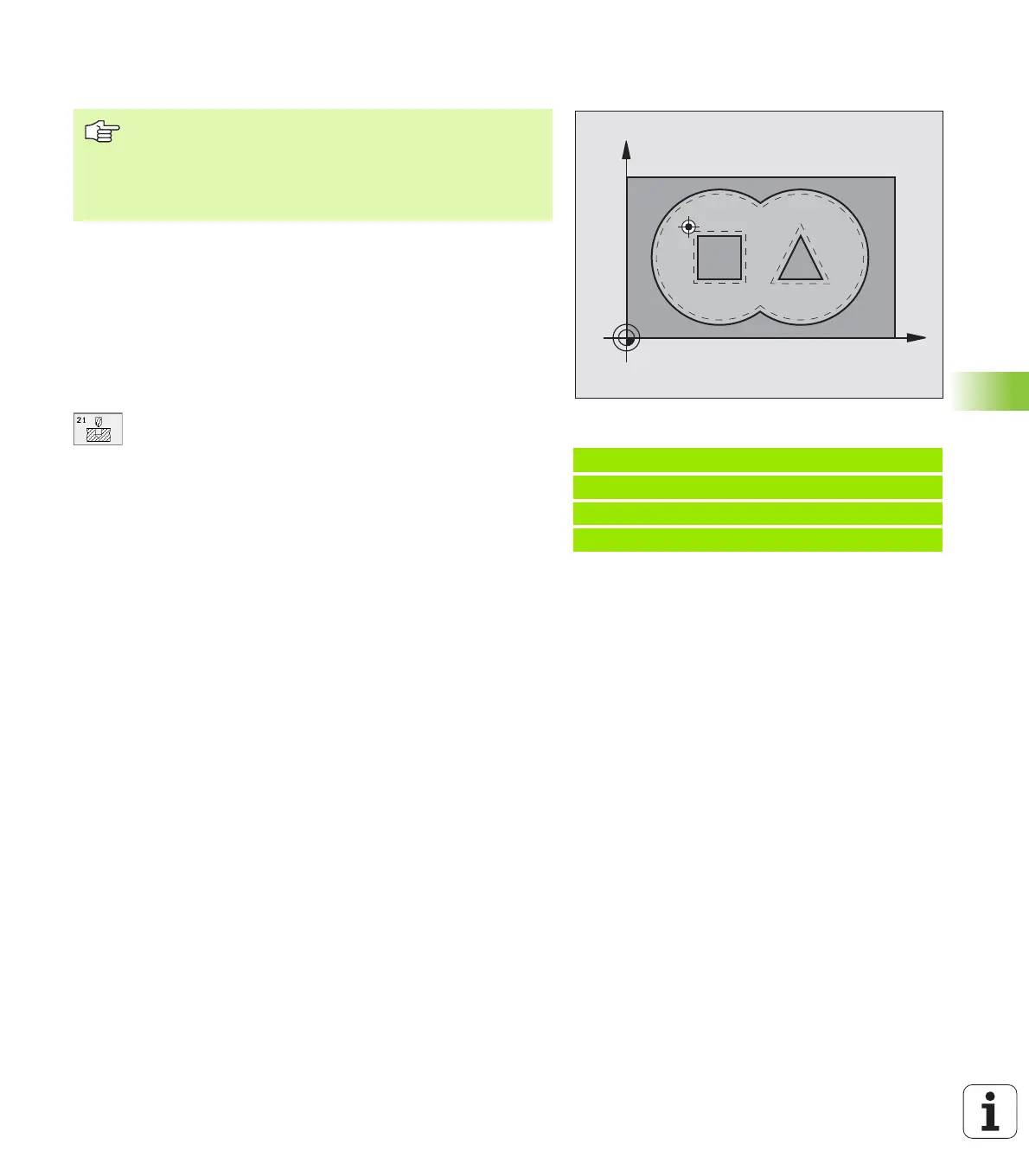

Cycle 21 is for PILOT DRILLING of the cutter infeed points. It accounts

for the allowance for side and the allowance for floor as well as the

radius of the rough-out tool. The cutter infeed points also serve as

starting points for roughing.

U Plunging depth Q10 (incremental value): Dimension

by which the tool drills in each infeed (negative sign

for negative working direction)

U Feed rate for plunging Q11: Traversing speed in

mm/min during drilling

U Rough-out tool number Q13: Tool number of the

roughing mill

Example: NC blocks

58 CYCL DEF 21.0 PILOT DRILLING

Q10=+5 ;PLUNGING DEPTH

Q11=100 ;FEED RATE FOR PLUNGING

Q13=1 ;ROUGH-OUT TOOL

X

Y

When calculating the infeed points, the TNC does not

account for the delta value DR programmed in a TOOL

CALL block.

In narrow areas, the TNC may not be able to carry out pilot

drilling with a tool that is larger than the rough-out tool.

Loading...

Loading...