HEIDENHAIN TNC 426, TNC 430 343

9.2 Subprograms

9.2 Subprograms

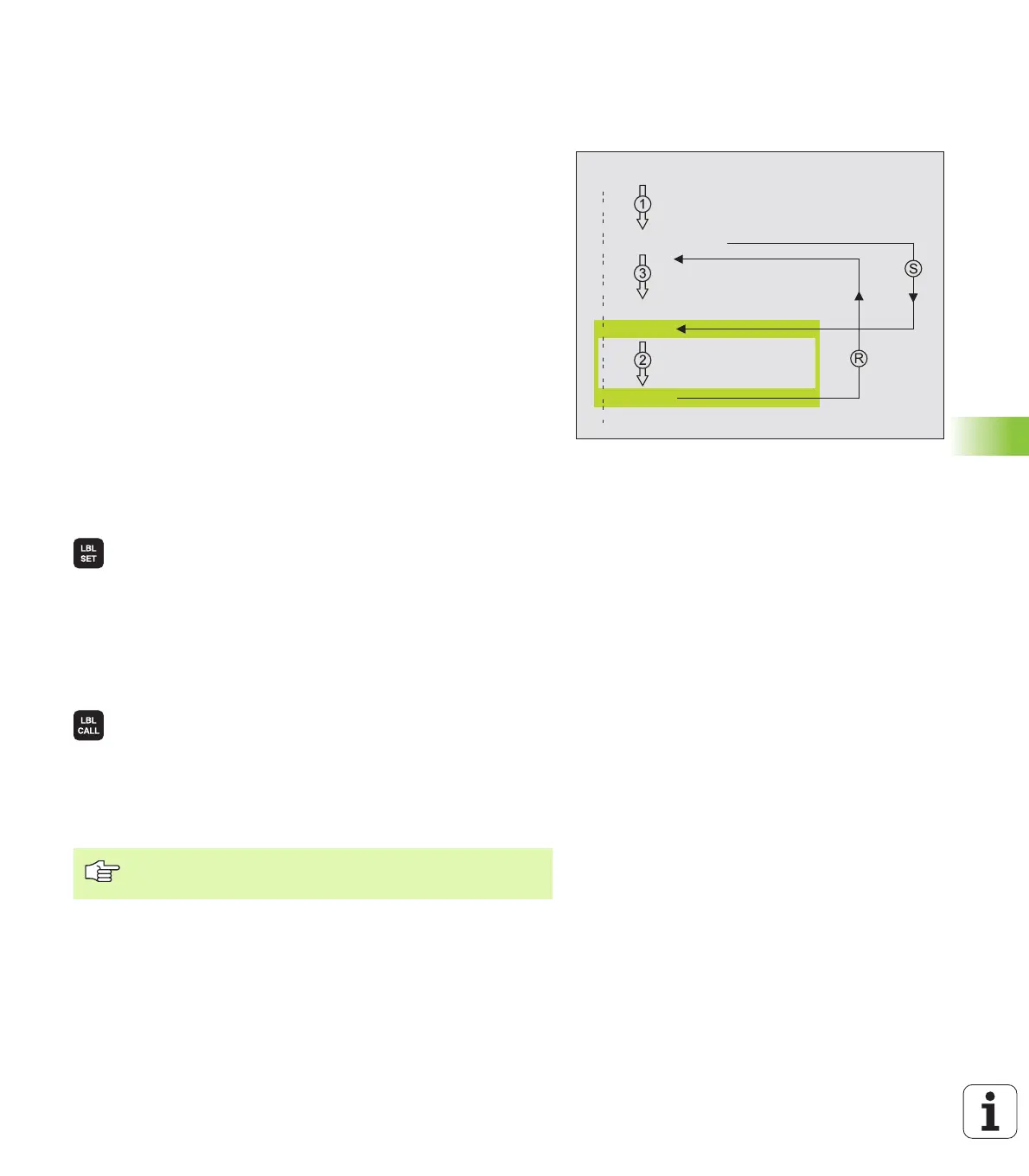

Operating sequence

1 The TNC executes the part program up to the block in which a

subprogram is called with CALL LBL.

2 The subprogram is then executed from beginning to end. The

subprogram end is marked LBL 0.

3 The TNC then resumes the part program from the block after the

subprogram call.

Programming notes

n A main program can contain up to 254 subprograms.

n You can call subprograms in any sequence and as often as desired.

n A subprogram cannot call itself.

n Write subprograms at the end of the main program (behind the block

with M2 or M30).

n If subprograms are located before the block with M02 or M30, they

will be executed at least once even if they are not called.

Programming a subprogram

U To mark the beginning, press the LBL SET key and

enter a label number.

U Enter the subprogram number.

U To mark the end, press the LBL SET key and enter the

label number “0”.

Calling a subprogram

U To call a subprogram, press the LBL CALL key.

U Label number: Enter the label number of the

subprogram you wish to call.

U Repeat REP: Ignore the dialog question with the NO

ENT key. Repeat REP is used only for program section

repeats.

0 BEGIN PGM ...

CALL LBL1

L Z+100 M2

LBL1

LBL0

END PGM ...

CALL LBL 0 is not permitted (label 0 is only used to mark

the end of a subprogram).

Loading...

Loading...