FX-1/FX-1R Maintenance Manual

<Procedure>

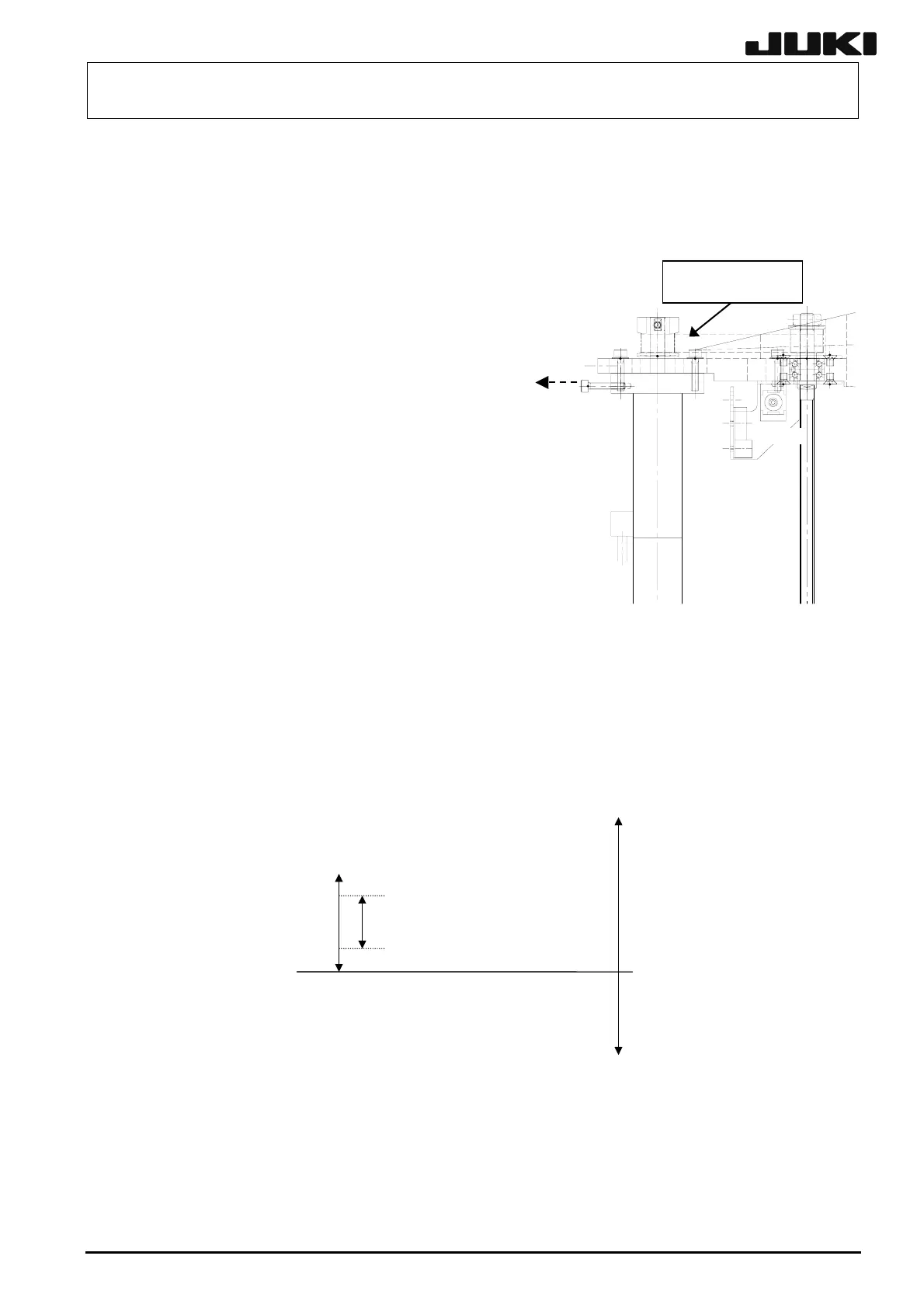

c Put the screw in the tap of the Z-motor and lock the mounting screw with the screw pulled in

the direction indicated by an arrow with a force of 21.6 N (2.2 kgf) using a tension gauge.

d Using a tension gauge, check that the belt tension is in a proper tension range of 10.5 ±1N.

2-5

Tension gauge set values

Weight: 0.9 g/m

Width: 8 mm

Span: 64.5 mm

Apply Loctite 242 to the Z-motor mounting

screws (3 pcs.) and tighten them with a

tightening torque of 2.3 Nm.

Pull

Timing belt Z

When tightening the setscrew of the Z-motor

pulley, make sure to align the orientation of the

flat part of the Z-motor shaft and the setscrew of

the pulley. Tighten the setscrew with a torque of

0.5 Nm.

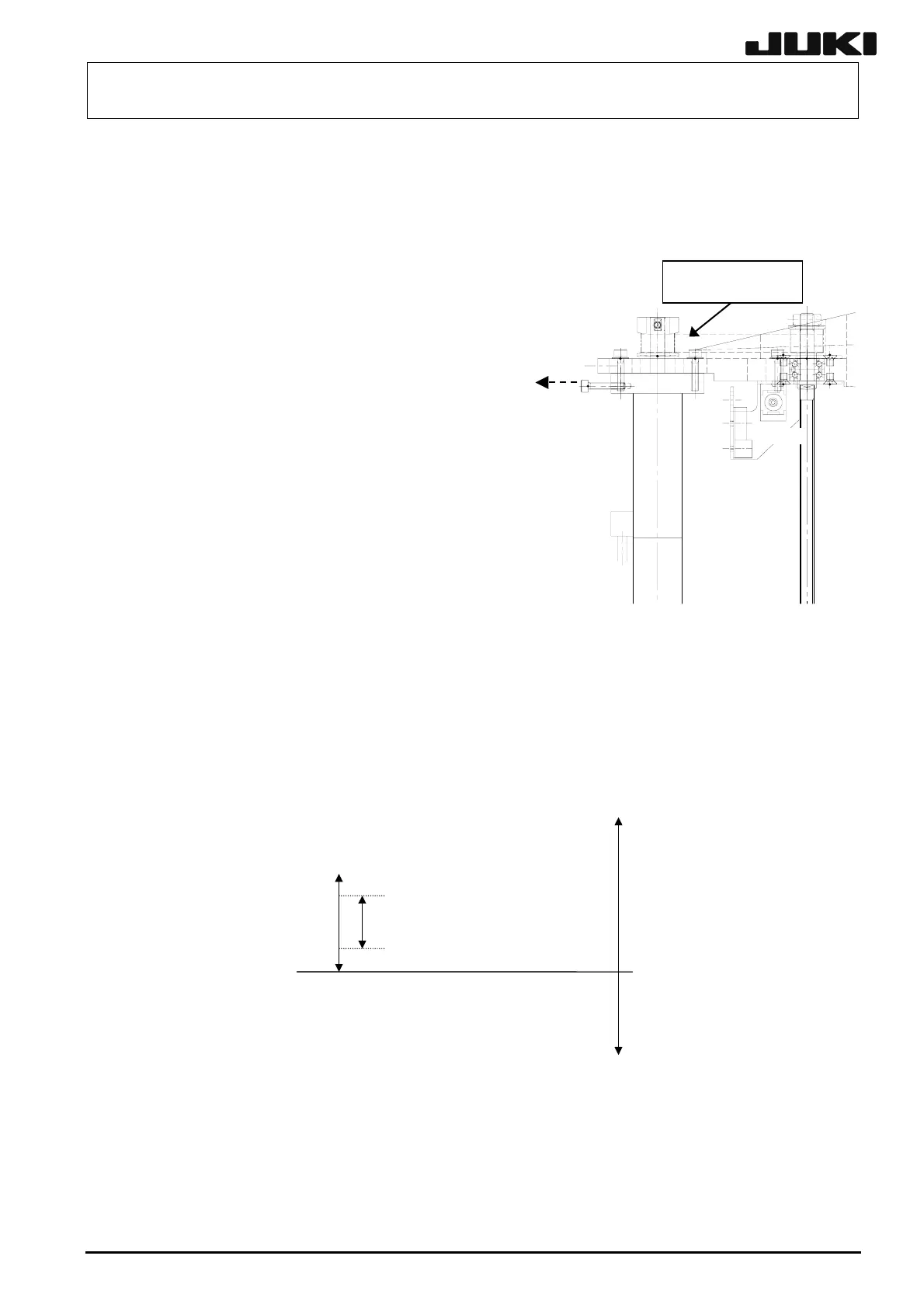

(7) After the Z-axis motor has been assembled, obtain the PWB top surface height of the MS

parameter. If this value is not in a range of 1 to 5 mm, shift the pulley and belt running part

positions. Obtain the MS parameter again and check that the PWB top surface height is in a

range of 1 to 5 mm.

1 to 5 mm Stable area

Z-sensor OFF area

6 mm

(Stroke for one rotation

of the Z-axis ball screw)

Z-sensor ON area

Rev. 2.00

Loading...

Loading...