6 8

KEB COMBIVERT F5

6

Name: Basis

05.05.04

Chapter Section Page Date

© KEB Antriebstechnik, 2002

All rights reserved

Functional Description Parameter Sets

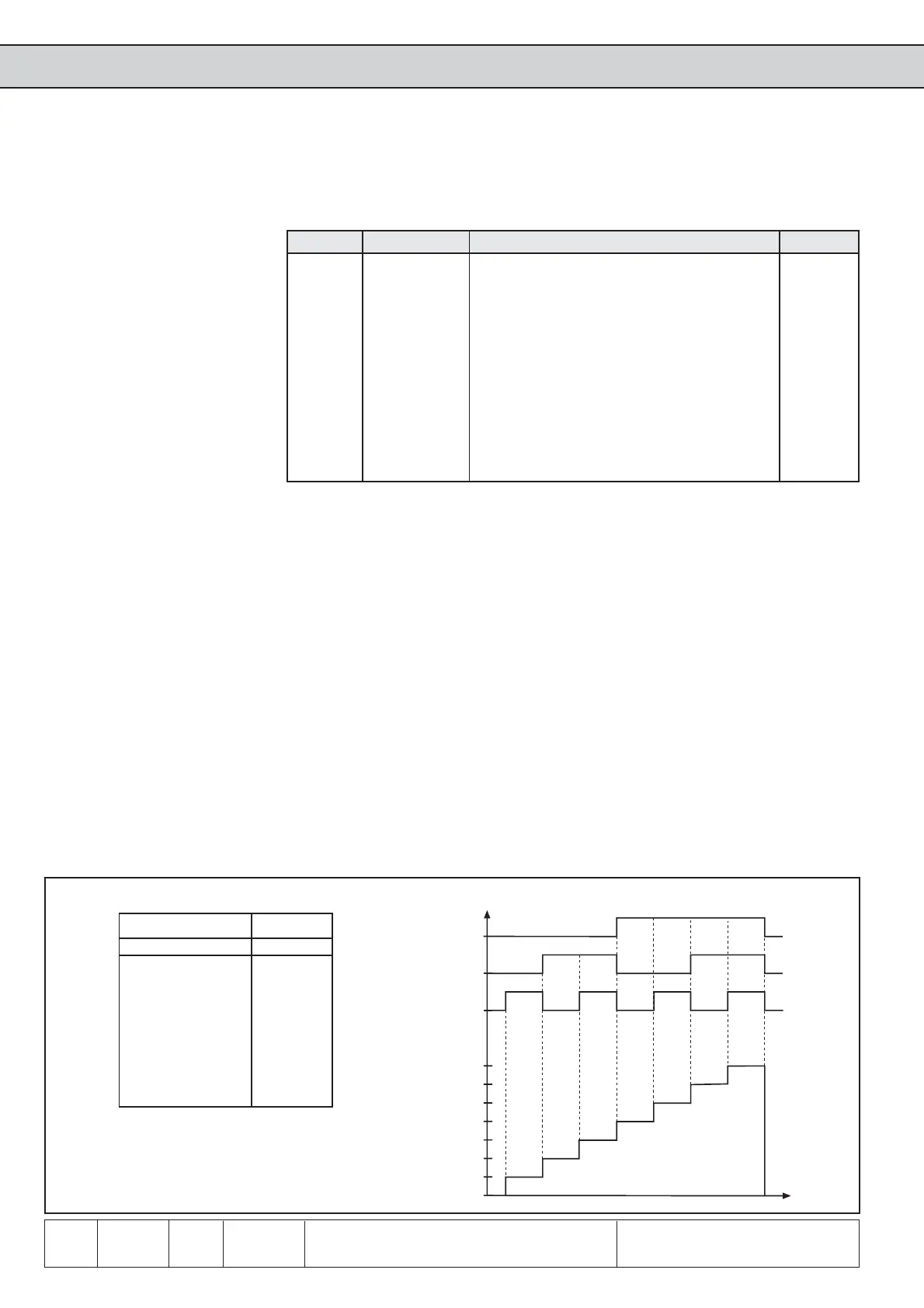

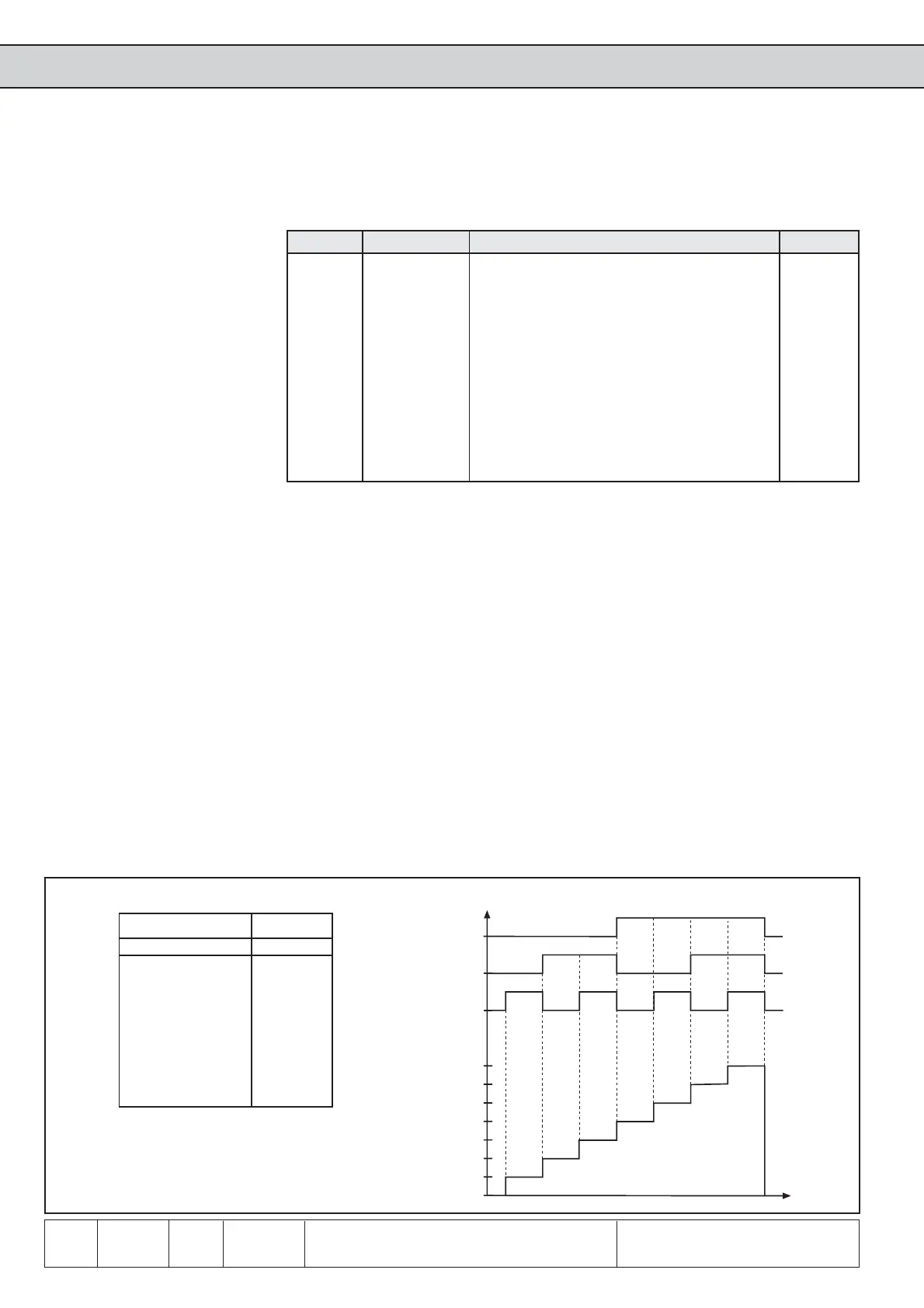

The adjustment via terminal strip can be made binary-coded or input-coded. The

inputs are defined with parameter Fr.7.

Binary-coded set selection

F

I1

I4

t

I4 I1 F Input

2² 2

1

2

0

Set

0000

0011

0202

0213

4004

4015

4206

4217

Fig. 6.8.7.b Binary-coded parameter set selection

Fr.7 Parameter set /

Input selection

With binary-coded set selection

- maximally 3 of the internal or external inputs may be programmed to set selection

(2

3

=8 sets) to avoid set selection errors.

- the valence of the inputs programmed for set selection rises

(ID>IC>IB>IA>I4>I3>I2>I1>R>F>RST>ST)

Example 1: With 3 inputs (F, I1 and I4) set 0...7 shall be selected

1.) Adjust parameter Fr. 7 to value „148“

2.) Adjust Fr.2 to value „2“ (set selection binary-coded via terminal strip)

1)

The input ST is occupied by hardware means with the function „Control release“.

Further functions can be adjusted only „additionally“.

Bit -No. Decimal value Input Terminal

01

1)

ST (Prog. input „Control release/Reset“) X2A.16

1 2 RST (Prog. input „Reset“) X2A.17

2 4 F (Prog. input „Vorwärts“) X2A.14

3 8 R (Prog. input „Rückwärts“) X2A.15

4 16 I1 (Prog. input 1) X2A.10

5 32 I2 (Prog. input 2) X2A.11

6 64 I3 (Prog. input 3) X2A.12

7 128 I4 (Prog. input 4) X2A.13

8 256 IA (Internal input A) none

9 512 IB (Internal input B) none

10 1024 IC (Internal input C) none

11 2048 ID (Internal input D) none

Set 7

Set 6

Set 5

Set 4

Set 3

Set 2

Set 1

Set 0

For input-coded set selection (Fr.2=3) I1, I2 and F are defined for set selection. In this

case F = set1; I1 = set2 and I2 = set3 would be acticated as the valence is (I2>I1>F).

If I1 and I2 are triggered simulateously the inverter switches into set2 since the priority

is F>I1>I2 at Fr.2.

Example

Loading...

Loading...