3

2

1

6

- 35 - - 35 -

Disassembly / Reassembly

Oil-bath air cleaner

Danger – Attention

Never clean the ltering element 6 using solvents with a

highly ash point. This could cause an explosion !

Caution – Warning

During repair operations, when using compressed air, wear

eye protection.

Checkgasketsandreplaceifnecessary.

Checkthatangeweldsarefreeofporosityordefectivespots.

Carefully clean bowl and ltering element with Diesel fuel and

drywithcompressedair.

Topupengineoiltothemark(seebelow).

Whenrettingtightennutsto25Nm

Seepage22forperiodiccleaningandoilreplacement.

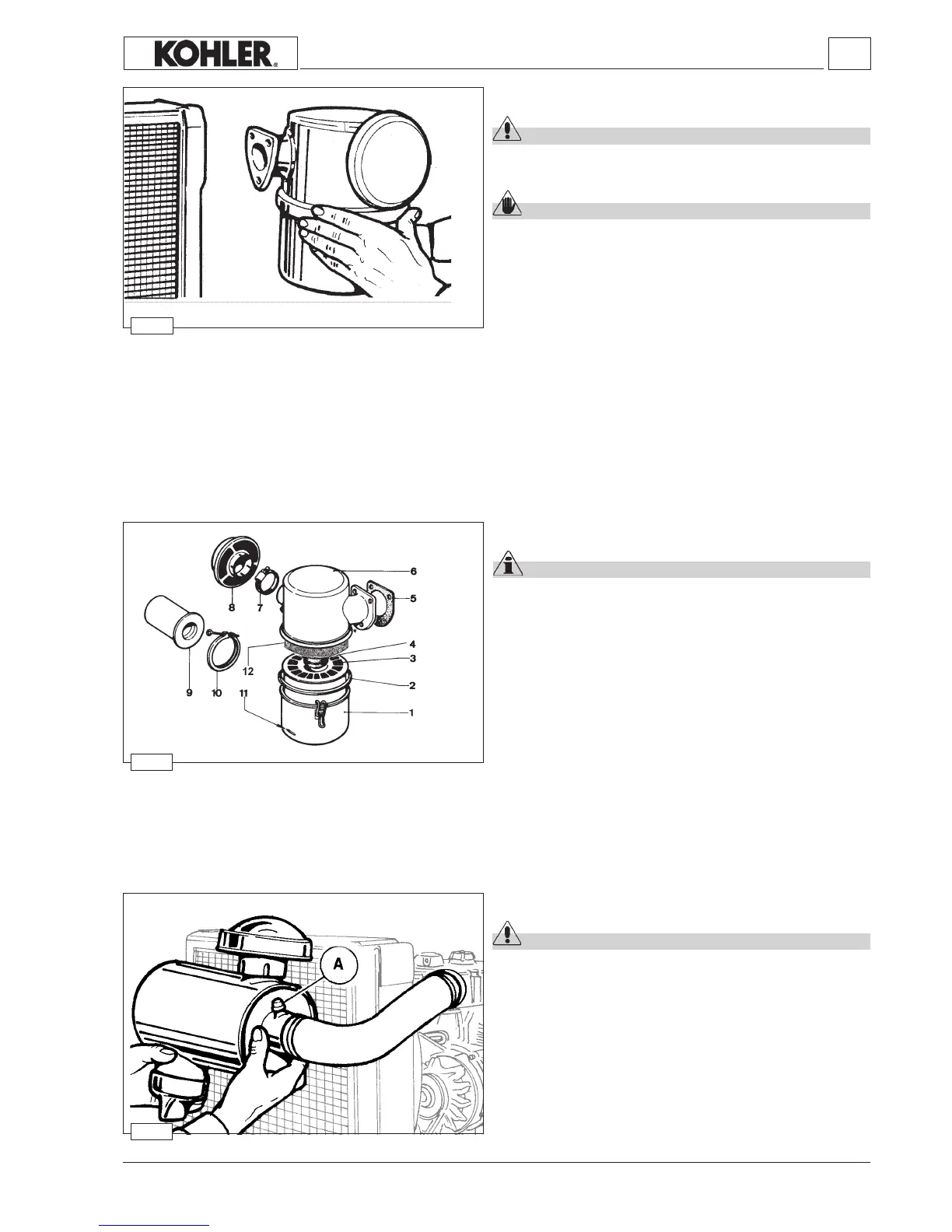

Oil-bath air cleaner components

Important

Check the sealing rings regularly.

Replace the sealing rings if hardening or damage is noted

1Bowl

2 Outersealring

3 Lowerlteringelement

4Innersealring

5 Gasket

6 Cover

7Capclamp

8 Cap

9Centrifugalpre-lter

10 Centrifugalpre-lterclamp

11 Oillevelmark

12 Upperlteringelement(polyurethansponge)

Note:Centrifugalpre-lter9istteduponrequest.

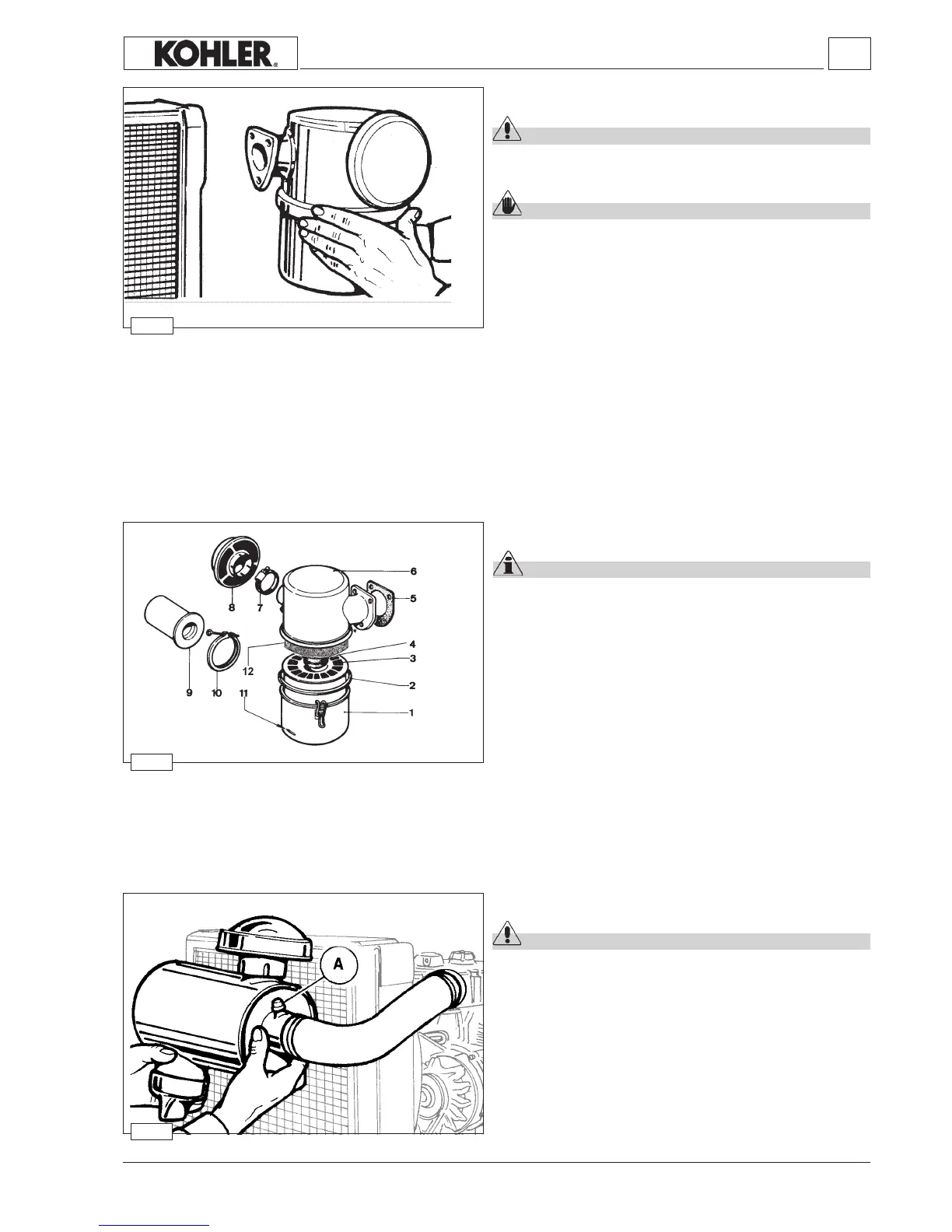

Dry air cleaner

Danger – Attention

Never clean the ltering element using solvents with a low

ash point. This could cause an explosion !

A =Fittingtoaccomodatecloggingindicator

Seepage22forperiodicdryaircleanercheckandreplacement

andtherubberintakehose(airlter-intakemanifold).

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...