90

92

91

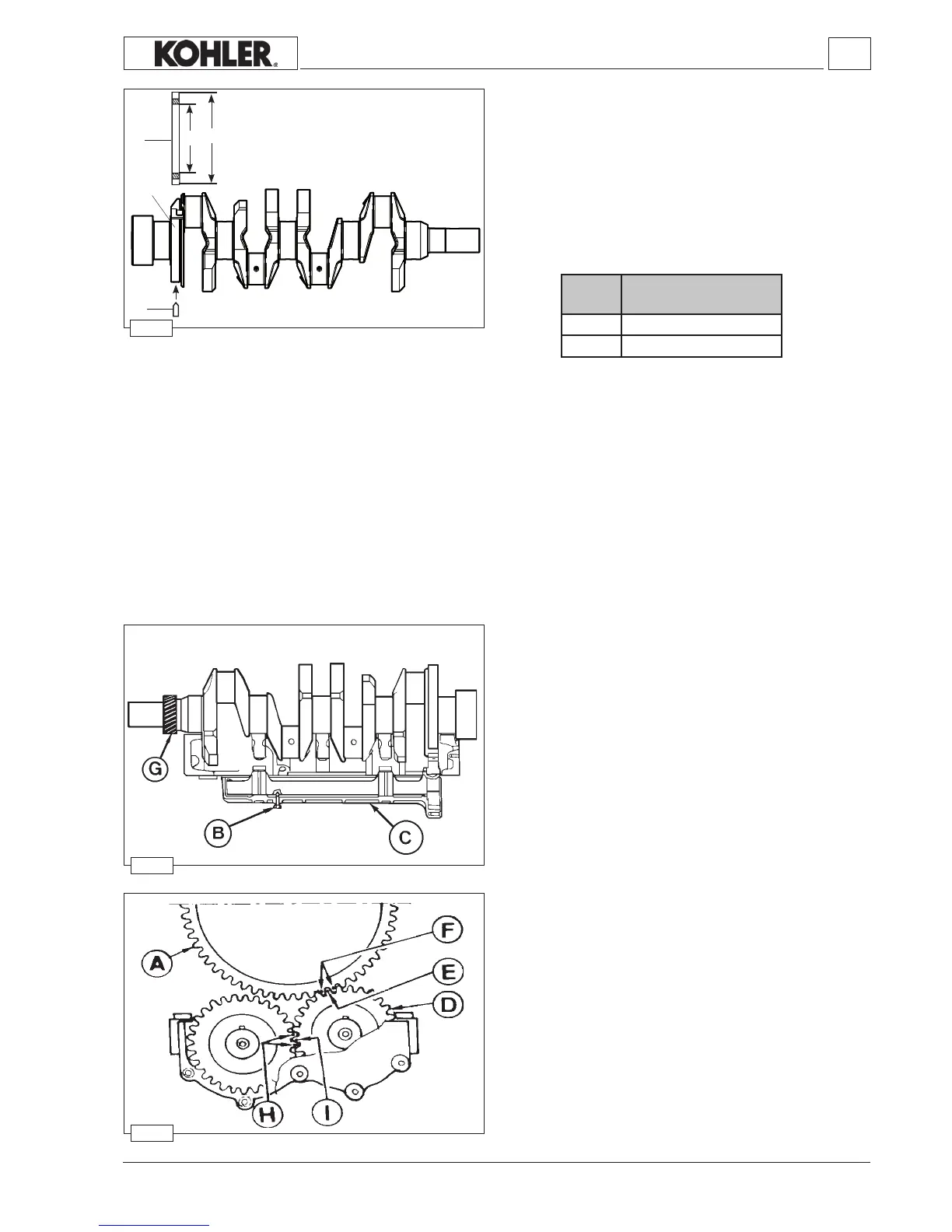

L 132,00÷132,03

M 132,07÷132,09

6

1

3

2

L M

- 57 - - 57 -

Disassembly / Reassembly

Crankshaft for engines with dynamic equalizer

(only four-cylinder engines).

The crankshaft comes with seat for the control gear of the

counter-rotatingshaftdynamicbalancer.

Withcenteringhole(springpin).

Components:

1

Controlgearforcounter-rotatingshafts

2Seatforthecontrolgearofcounter-rotatingshafts

3Dowelpin

Toreplacethegearheatitupto180°÷200°C.

Locateitintoitsseatsothatthetiming referencemarksonthe

teetharefoundontheyweelside.

Ref.

Dimensions (mm)

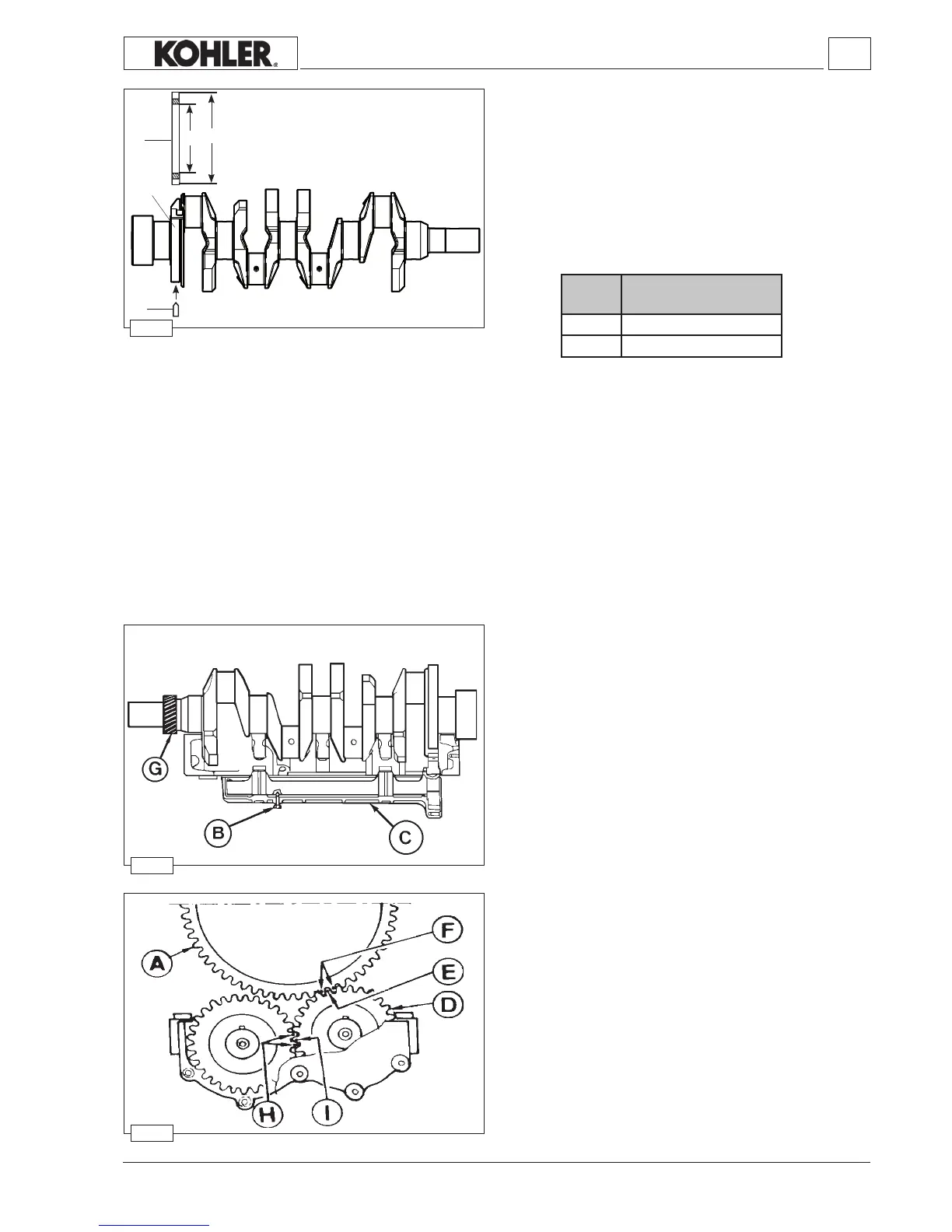

Dynamic balancer (on request) -

Adjustment of clearance between teeth D and ring gear A

Followgures91and92.

ScrewthescrewBintosupportCtakingcaretocentrethehole

inthemassofthegearDtolockit.

Fit the mass assembly under the crankcase so that the tooth

with reference E goes between the teeth with references F of

Controlgeardynamicbalancer.

Fix the mass assembly with the four M10 screws to the

crankcase,provisionallytighteningitto40Nm.

Don'tremovescrewB.

By making the driving shaft turn, check the clearance between

theringgear A andthegearofmassD;setacomparator with

thefeelerononetoothof the timing systemcontrol gear G;by

turning thedriving shafta little way check theclearance which

mustbe0.026÷0.067.

If the clearance measured does not come within the values

given,repeattheoperationplacingthe0.05mmshimsprovided

foradjustmentbetweenthesupport Candthecrankcase.

When mounting the balancer, lubricate the bushings with

Molikote then couple the two masses, taking into account the

referencesHandI.

PermanentlyxthesupportCtothecrankcasebytighteningthe

screwsto50Nmplusoneturnofthewrenchclockwisethrough

45°.

The four screws will have to be mounted with a few drops of

Loctite242.

RemovescrewB.

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...