4

1

2

5

3

4

6

7

8

5

B

A

1

2

3 4

9

6

- 36 - - 36 -

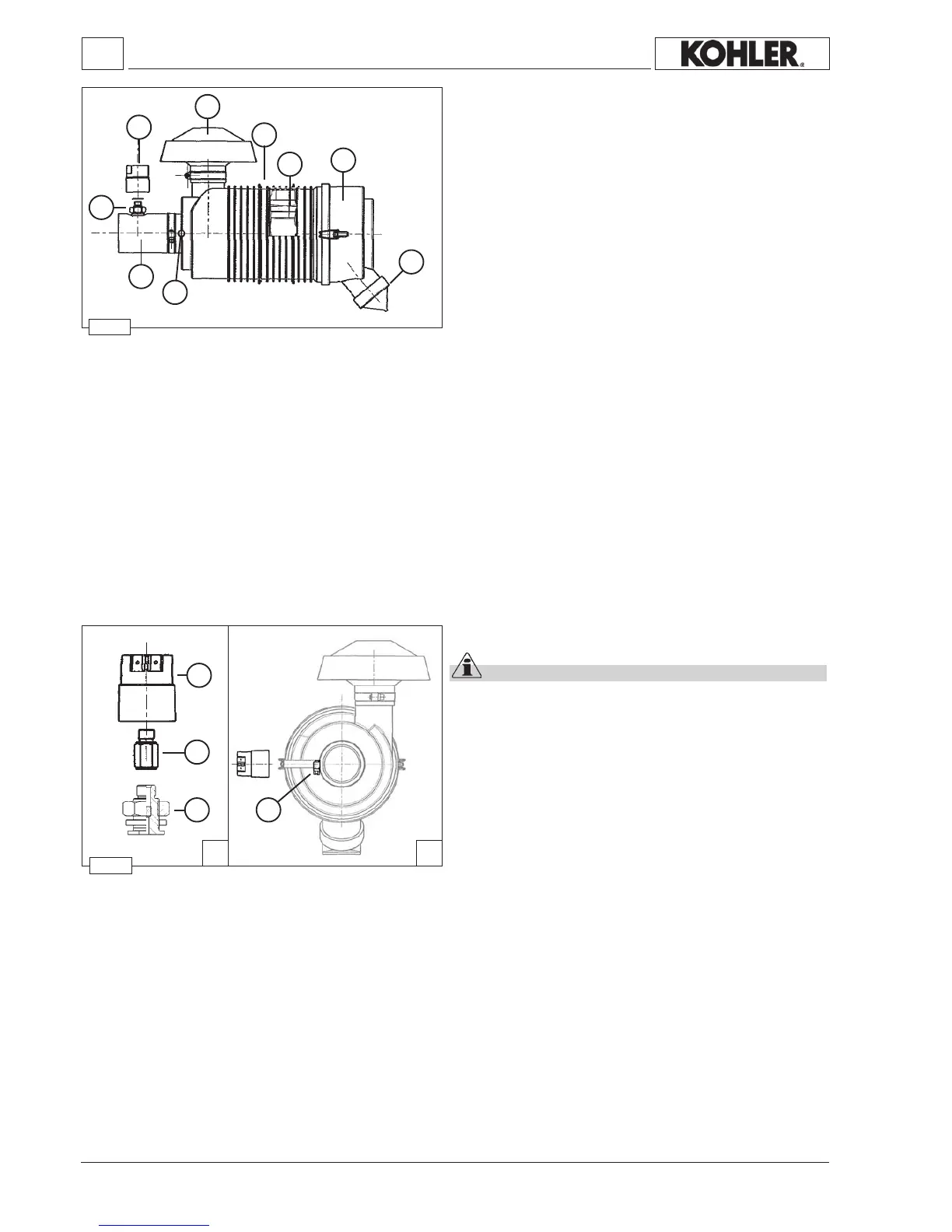

Disassembly / Reassembly

Dry air components

1Maincartridge

2Safetycartridge

3 Axialcover

4Vacuatorvalve

5Capcompletewithclamp

6 Rubber connecting hose to the air lter - manifold or

compressor.

7 Airlterrestrictionswitch

8

Mountingforcloggingindicator

9Fastener

Scavengingvalve4mustbepositionedasingure4.

The cartridge can be cleaned by blowing compressed air

breadthwaysoutsideandinsidethecartridge,atapressurenot

greaterthan5atmospheres,orinnecessitycasebyknockingthe

frontofthecartridgeseveraltimesagainstaatsurface.

Use a lamp to check that the lter element is not damaged or

inspectitagainstthelightwhileslanted.Incaseofdoubt,install

anewcartridge.

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

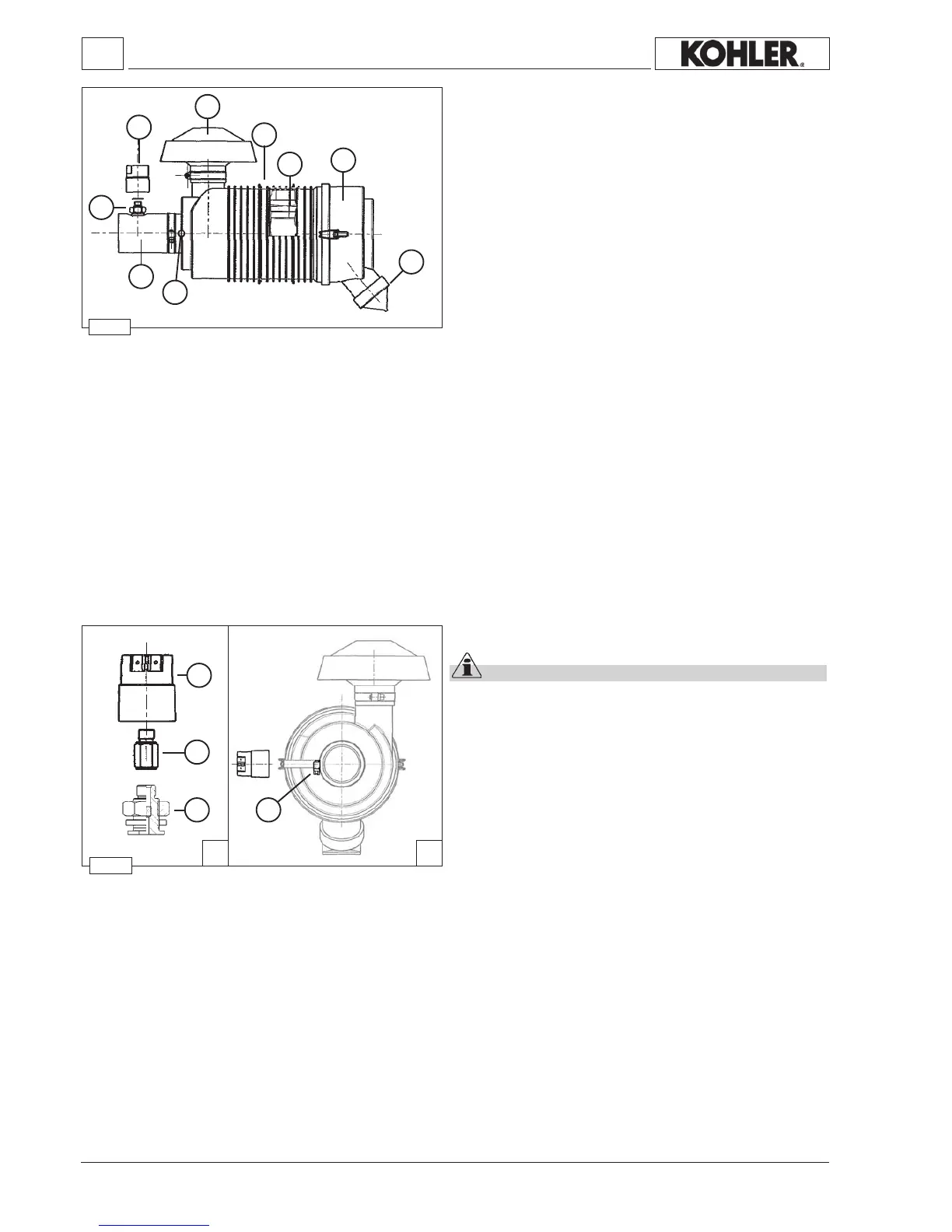

Air lter clogging indicator

Important

The indicator has to be tightened to mounting 4, as shown

in g. 5 B. Due to space requirements, it can be assembled

by using special fastener 3 (g. A) and by creating a hole of

Ø14-15 mm in the rubber hose (see g. 4).

1

Airlterrestrictionswitch

2 Turboadapter

3 Fastener

4 Mountingforcloggingindicator

Note: Therearetwotypes:oneforanaspiratedengineandone

forasuperchargedengine.

Setting for aspirated engine(KDW 1603 - 2204) = 635

mmcolumnofwater.

Setting for supercharged engine (KDW 2204/T) = 380

mmcolumnofwater.

Loading...

Loading...