38

37

39

6

- 45 - - 45 -

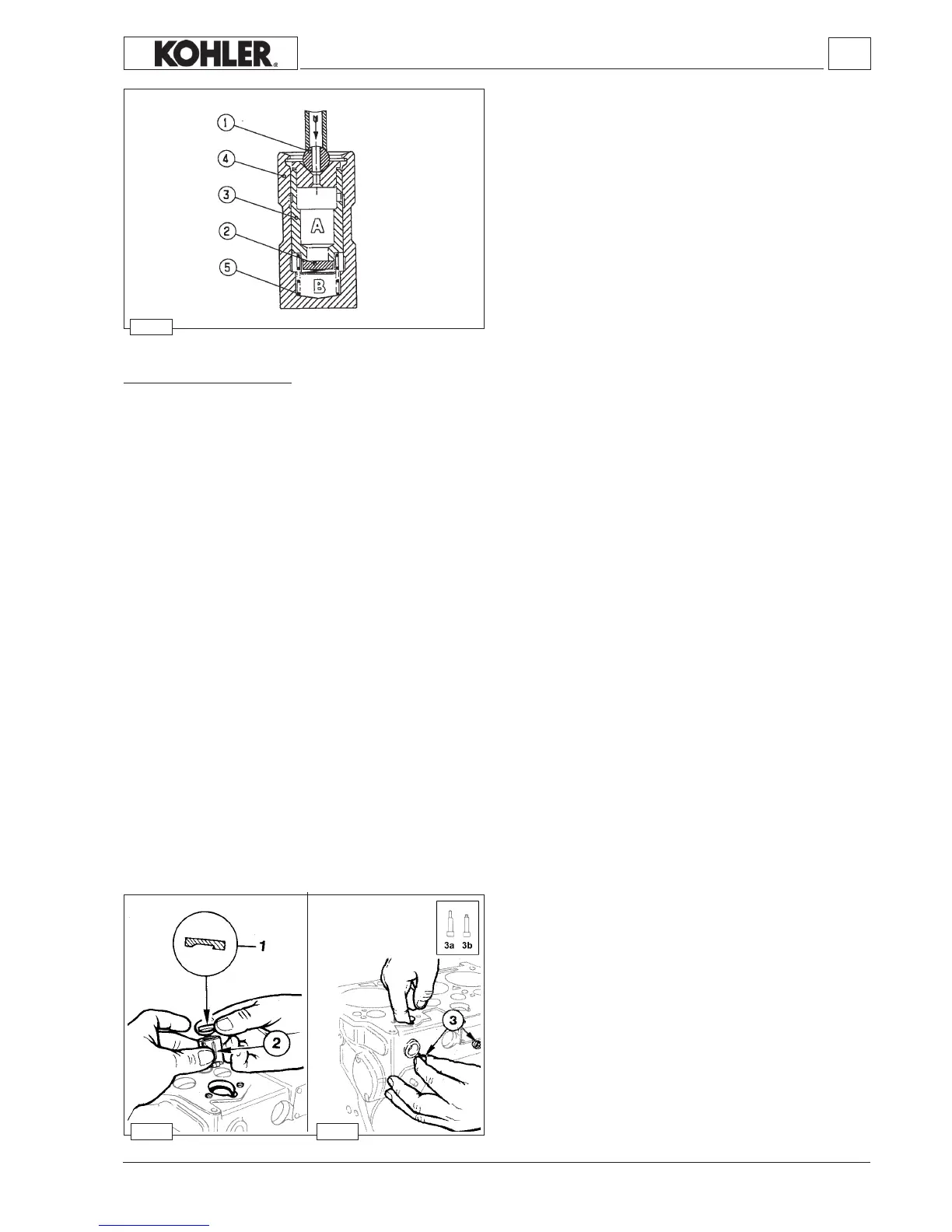

Hydraulic tappet operation

The operatingprinciple of thehydraulic tappet isbased on the

incompressibilityoftheliquidsandoncontrolledleakage.

Through pushrod 1, the pressurised oil gets into thetappet in

chamberA(low-pressurechamber),maintainingaconstantowof

oilintheabovechamberaswellasinthehigh-pressurechamberB.

TheoilcanonlyenterchamberBthroughthenon-returnvalve2

andleavethroughtheclearancebetweentheplunger3andthe

tappetbody4(controlledleakage).

ChamberB isrelledwhenthetappetisonthebottomofthecam

baseandspring5 keepsplunger3 pressed,thuseliminatingthe

clearance in the entire valve-rocker arm-push rod-tappet-cam

system.

Thetappetbodymovesawayfromtheplungercreatingaslight

vacuuminchamberB andcausingthevalve2 toopen,thusallowing

theoilinchamberA toowintochamberB,re-establishingthe

quantityofoilrequiredforoptimalrunningconditions.

Difcultoperatingconditions:

Forcorrectfunctioningofthehydraulictappetsthepressurechamberofplunger 3mustalwaysbelledwithoil.

However,thisisnotpossibleinsomeconditionsinthat,whentheengineisnotrunning,oilleakagesmaycausepartialemptying

ofthetappets.Thissituationwillcauseexcessiveclearancewhichwillmakeitselfapparentthroughanunusualtickingsoundthat

isnottobeconfusedwiththenormaltickingoftheinjectors.

1 -Startingfromcold:theenginehasnotbeenusedforsometimeandoilmayhaveleakedoutofthepressurechamberofthe

tappets.Moreover,lubricantowswithgreaterdifcultyatlowtemperatures,andhenceseveralsecondsmaygobybefore

thetappetsareonceagainsuppliedwithoil.

2 - Engine very hot: at minimum speed, the oil pressure is low and tiny air bubbles may form inside it (more than 5% of its

volume).Thiscausesthelubricanttobecomecompressibleandthetappetissqueezedslightlycreatingclearanceand,

thusmakinganoise.

3 - Startingandstoppingtheenginerepeatedly(veryrare):inthissituationthetappetsmayemptytemporarily.

4 - Anoilwithaviscositynotadequatetotheenvironmentalconditionsoftheenginemayaffecttheproperfunctioningofthe

hydraulictappets.

Forthedeterminationoftheadequateviscosityofoilreferredtopage.29.

Inallfourcasesthetickingshouldnotlasttoolong.Ifthisisnotthecase,theproblemisdenitelyduetoamanufacturingfault,

wearandtearordirt,whichcanbedrawninbytheoilandgetbetweenthenon-returnvalveanditsseatinsidetheplunger,thus

compromisingthefunctioningofthetappets.Inthiscasethehydraulictappetsmustbereplaced.

Injection pump follower

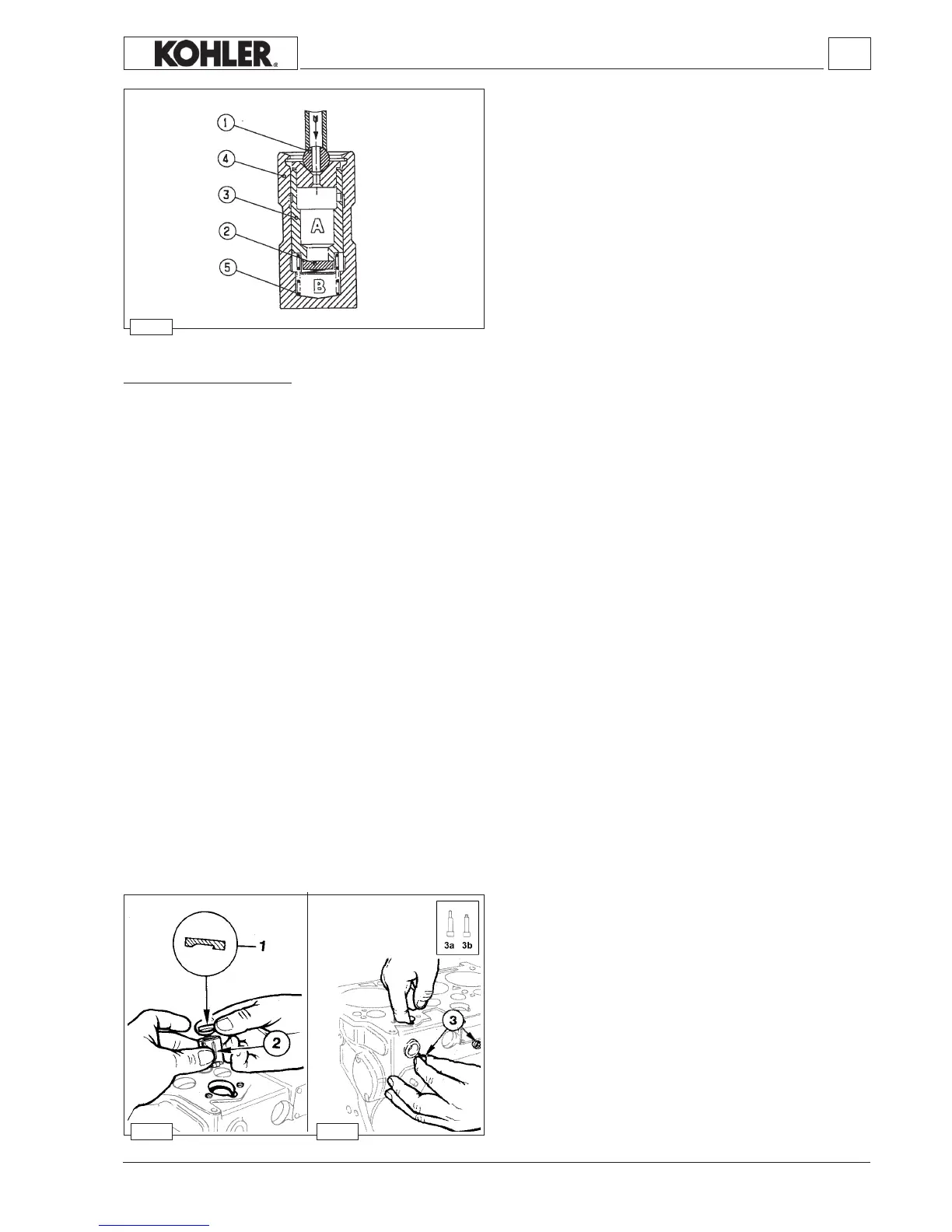

Introducethefollowerintoitshousingandmanuallyturnscrew3

untilitmatcheswithnotch2.

Beforelockingscrew3useyourngertocheckthatthefollower

isallowedtomoveupwardsfreely.

Space 1 should be introduced into the pushrod with the at

surfacefacingupwards

Note: The screws 3a can be tted without distinction in each

cylinder.

Screw3b however,whichisshorterthantheothers,has

to be ttedon thetiming sideof thecylinder (insidethe

stoplevercover).

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...