45

43

42

40 41

46

44

D(mm)

88,00÷88,01 88,100

A 88,00÷88,01 87,960÷87,967 0,033÷0,050

6

- 46 - - 46 -

Disassembly / Reassembly

Cylinders

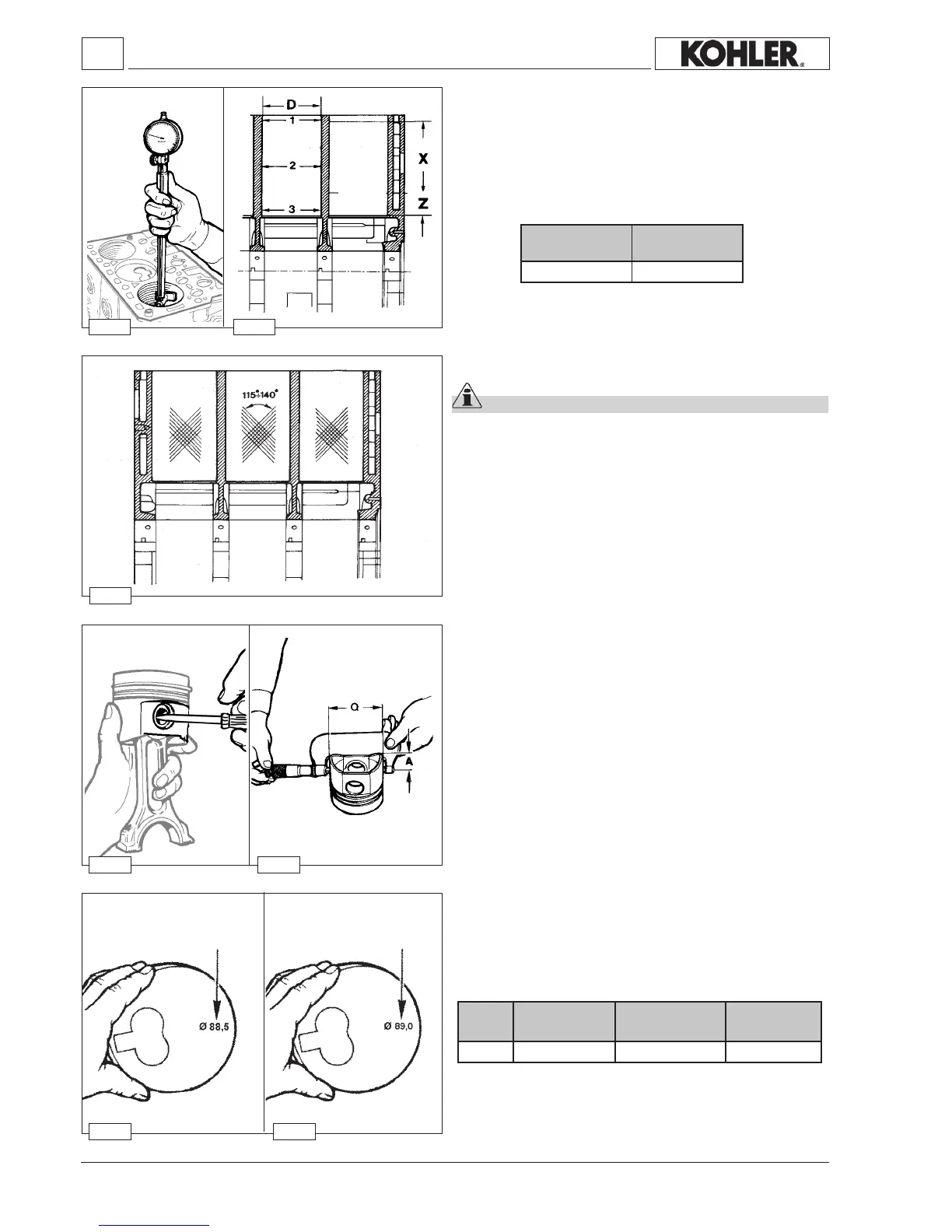

Resetdialgaugewithacalibratedring.

CheckdiametersizeDat1,2and3;repeatthesameoperation

atthesameplacesafterturningthedialgaugeby90°.

CheckforwearintheXareawherepistonringsarelocated.

To check clearance with the matching piston measure the

diameter size at Z along theaxis whichruns atright anglesto

thedrivingshaft.

Limit value

(mm)

Cylinder roughness

Important

Do not manually hone the cylinder bore surfaces with

emery cloth or other means.

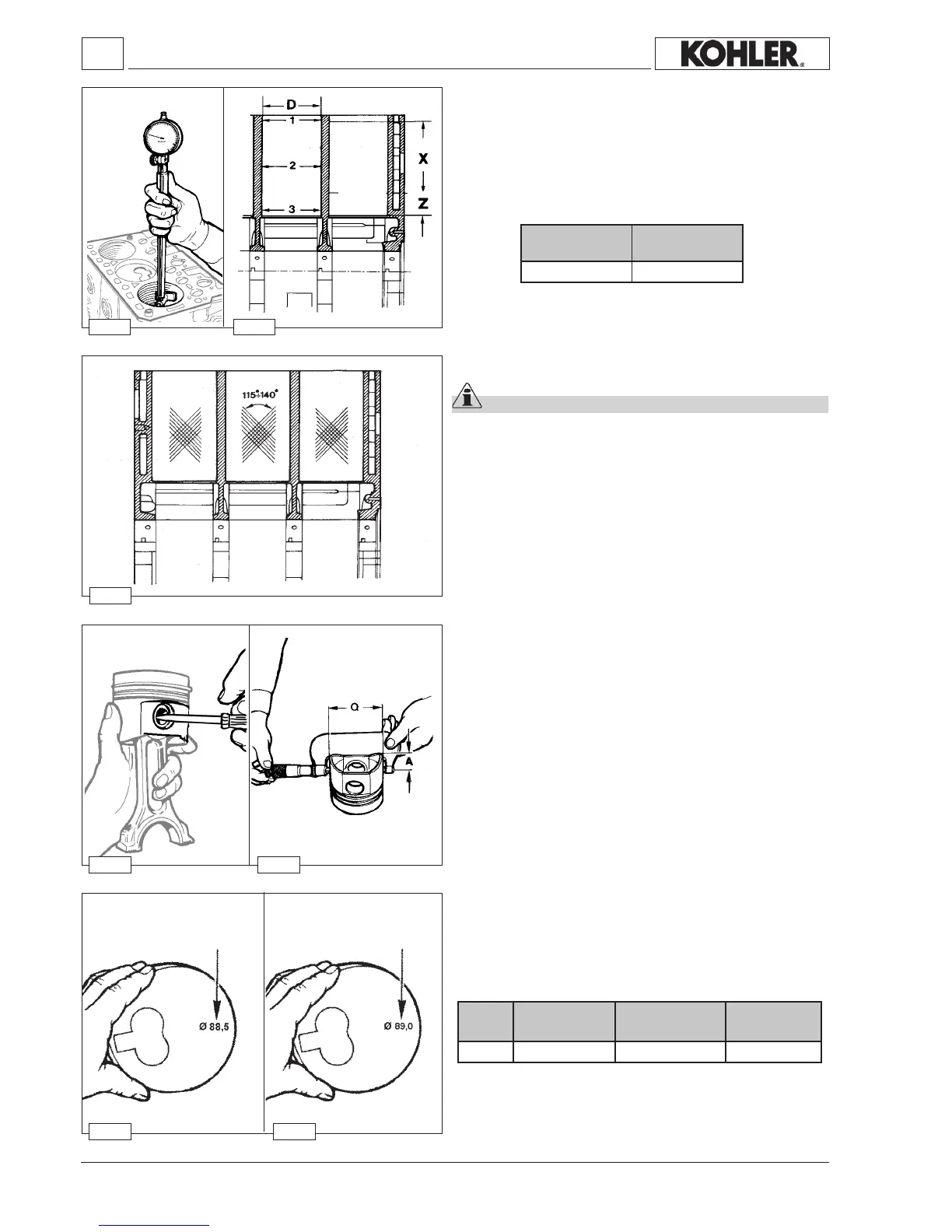

The inclination of the cross-hatched marks left by machining

should range between 115°-140°; they should be uniform and

clearlyvisibleinbothdirections.

Averageroughnessshouldrangebetween0.5and1mm.

The cylinder surface which comes into contact with the piston

ringsshouldbemachinehonedwiththeplateausystem.

Piston

Removecirclipsandpistonpin.

Removepistonringsandcleangrooves.

Measure diameter Q at the A distance from the bottom of the

skirt(A=12mm)

In case of diameter wear exceeding 0.05 mm of the minimum

givenvaluereplacepistonandrings.

Nota:Theoversizesare0.50and1.00mm.TheTURBOpiston

differs from that of the NATURALLY ASPIRATED in its

coolingsprayerpassagenicheandaninsertintheslotof

therstring.

Piston availability

Thepistonsoversizedby0.5and1.0mmhavetheupratingreference

onthecrown,g.45-46.

Class

Ø Cylinder

(mm)

Ø Piston

(mm)

Clearance

(mm)

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...