55

54

52 53

0,68÷0,83

0,68÷0,81

0,67÷0,82

0,72÷0,85

0,83÷0,98

0,81÷0,94

0,67÷0,82

0,69÷0,82

0,98÷1,10

0,94÷1,07

0,67÷0,82

0,66÷0,79

A (mm)

6

- 48 - - 48 -

1603

2204-2204/T

1603

2204-2204/T

1603

2204-2204/T

Disassembly / Reassembly

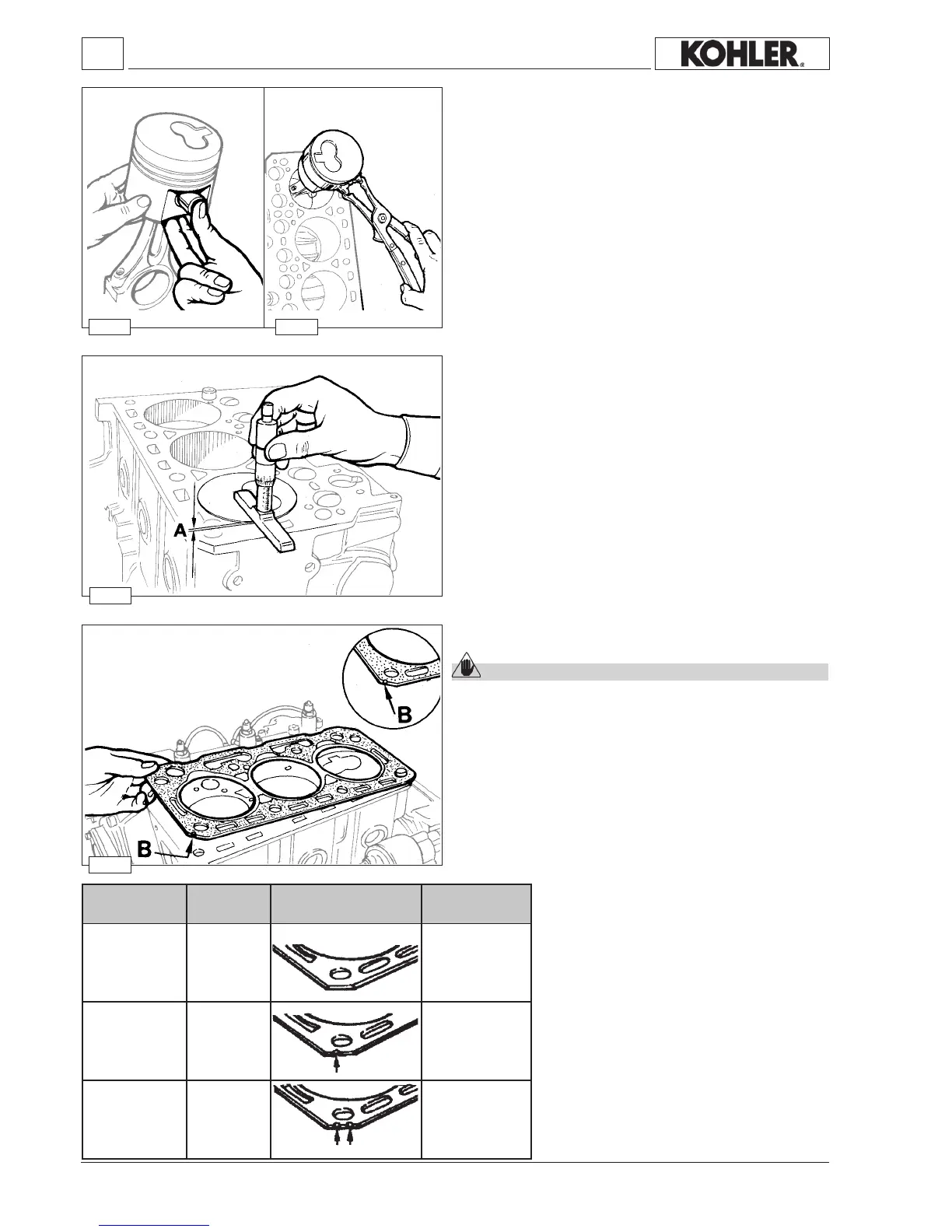

Piston - Retting

Connectpistontoconnectingrodafterlubricatingpistonpinand

introducingitbyexertingpressurewithyourthumb.

Positionthetwopistonpincirclipsandcheckthattheyarewell

insidetheirseats.

Using a ring compressor introduce the piston into the cylinder

withcombustionchamberfacingtheinjectionpumpside.

Piston position and clearance

Toobtainaclearanceof0.67÷0.90mmmeasureprotrusionAof

all pistons fromthe cylinderplane andconsider the A value of

themostprotrudingpiston.

Performthismeasurementalongtheengineaxis.

Engine type No.of notches

Resulting clea-

rance (mm)

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

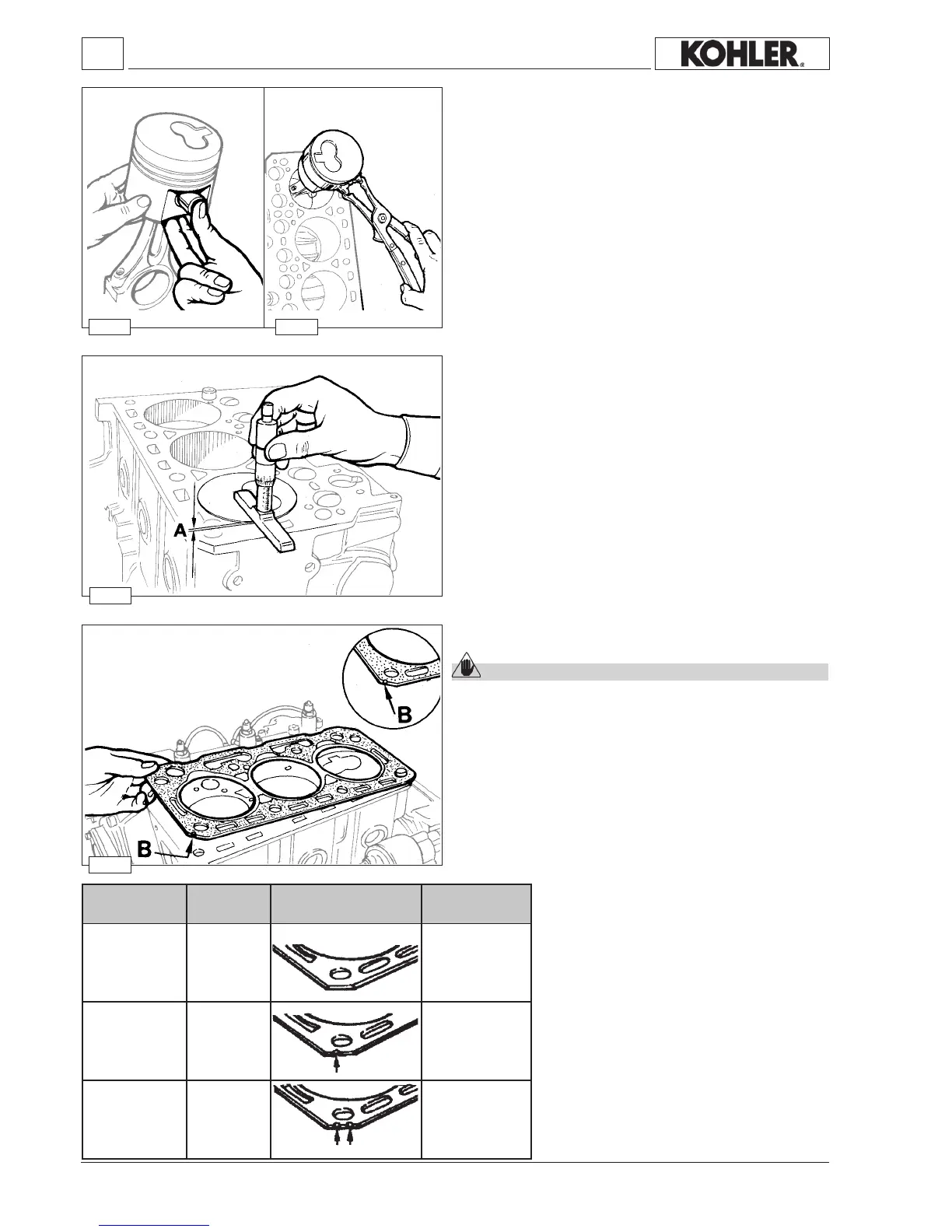

Cylinder head gasket

Caution – Warning

Remove the head gasket from its protective wrapping only

when ready for tting.

At B the gasket shows small semi-circular notches indicating

thickness.

Choosetheproperheadgasketconsideringthatforeachvalue

ofA (maximumprojectionofthepistonfromthecylindersurface)

there is a matching gasket among the three available (with no

notch,onenotchortwonotches)toachieveaclearancevolume

between0.66and0.90mm.

IntheLDW1603enginestheheadgasketismadeofbre,while

intheLDW2204/2204-Tenginestheheadgasketismetal.

Note: The notches shown above protrude

fromthecylinderheadplane;youcan

thus determine the gasket thickness

beforetakingdownthehead.

Loading...

Loading...