152

151

153

10

- 78 - - 78 -

1603-2204 2204/T

Ø7mm Ø7mm

Electric fuel pump (24V)

Theuseoftheelectricpumpisforeseenforcertainapplications

(wheretheenginehastobestartedatverylowtemperatures).

Assembly notes:

Whentheelectricfuelpumpisinstalled in a diesel engine,it is

necessaryto:

1) Removethelterttedatthepumpintake(intakeside).

2) Inserttheprelterupstreamofthepump(intakeside).

3) Theelectricpumpontheapplicationmustbeatsuchaheight

from the minimum tank level that it generates a maximum

pressuredropequaltoacolumnof500mmofwater.

4) Avoidrunningdryduetoemptyingoftheintakepipeline,inserting

anon-returnvalve.

Features:

Pressure:0.44/0.56bars

Maxcapacity:100l/h

Features

Pumping

Sealing

valve

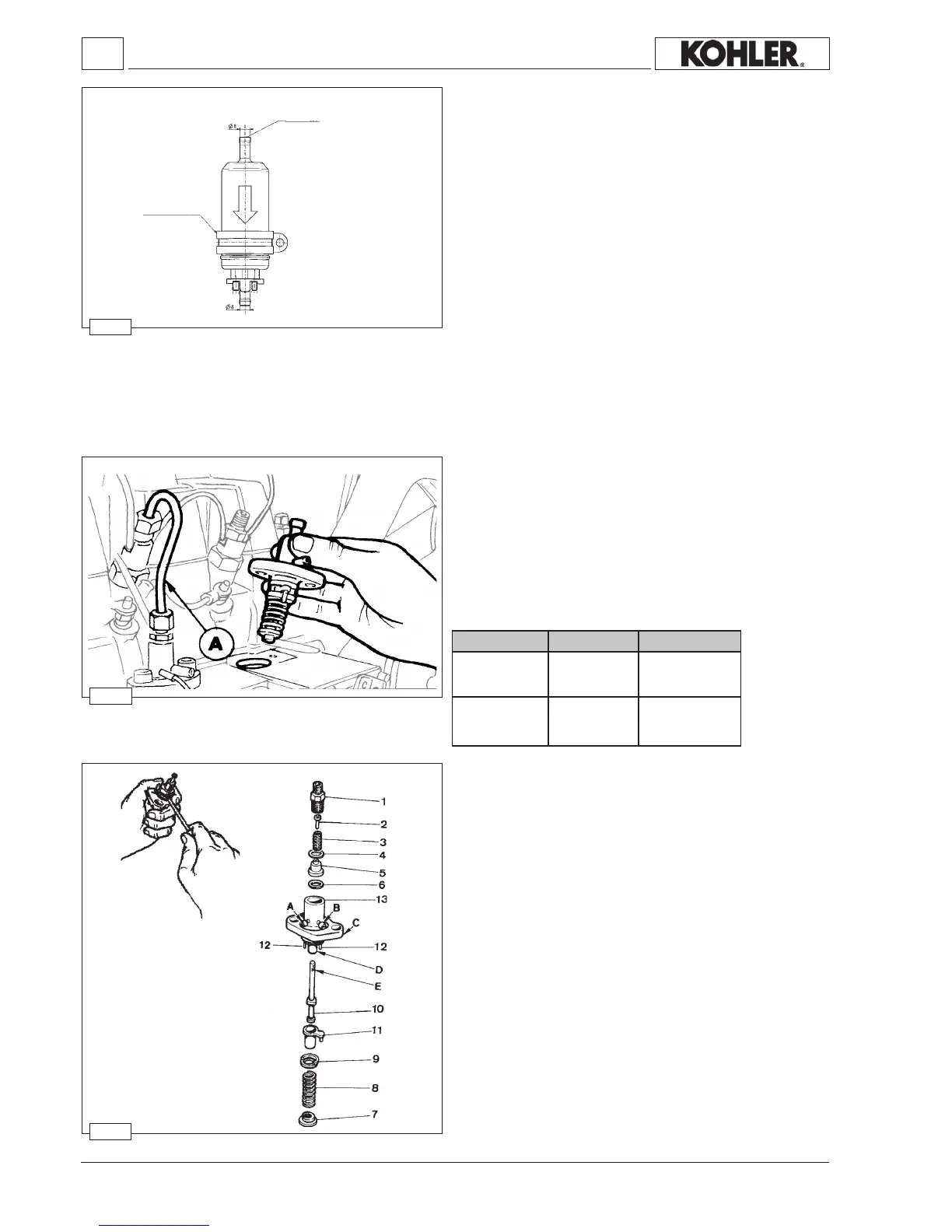

Injection pump disassembly

Releasethespringfromthecapandremovetheplunger.

Two pinskeeptheuppercapconnectedtothepumpbody;pry

withatoolbetweenthepumpbodyandthecap.

Injection pump components:

1Deliveryunion 8 Spring

2Spacer 9 Uppercap

3Spring 10Plungerpumping

4Gasket 11Lever

5Deliveryvalve 12Pin

6Gasket 13Body

7 Cap

AFuelfeedunion

BFueldischrgeunion

CPumpange

DBarrelpumping

EFuelcontrolhelix

Note: Union A and B, ange C and barrel D form an integral

partofthepumpbody.

Support

clump

Intake

side

Fuel system

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Injection pump

Theinjectionpumpofasimplied Qtypehasbeendesignedby

KOHLER for installation on engines of the KDW 1603-2204-

2204/Tseries.

The injection system includes three or four separate pumps

eachofwhichfeedsacylinder.

Located on the crankcase at the level of the corresponding

cylinder,pumpsaredirectlyoperatedbythecamshaft.

AllhighpressuretubesbetweeninjectorandpumpA featurethe

sameshapeanddimensions.

Volume25mm

3

1holeØ0,81

Volume25mm

3

3holesØ1,5

Loading...

Loading...