172

171

10

170

- 84 - - 84 -

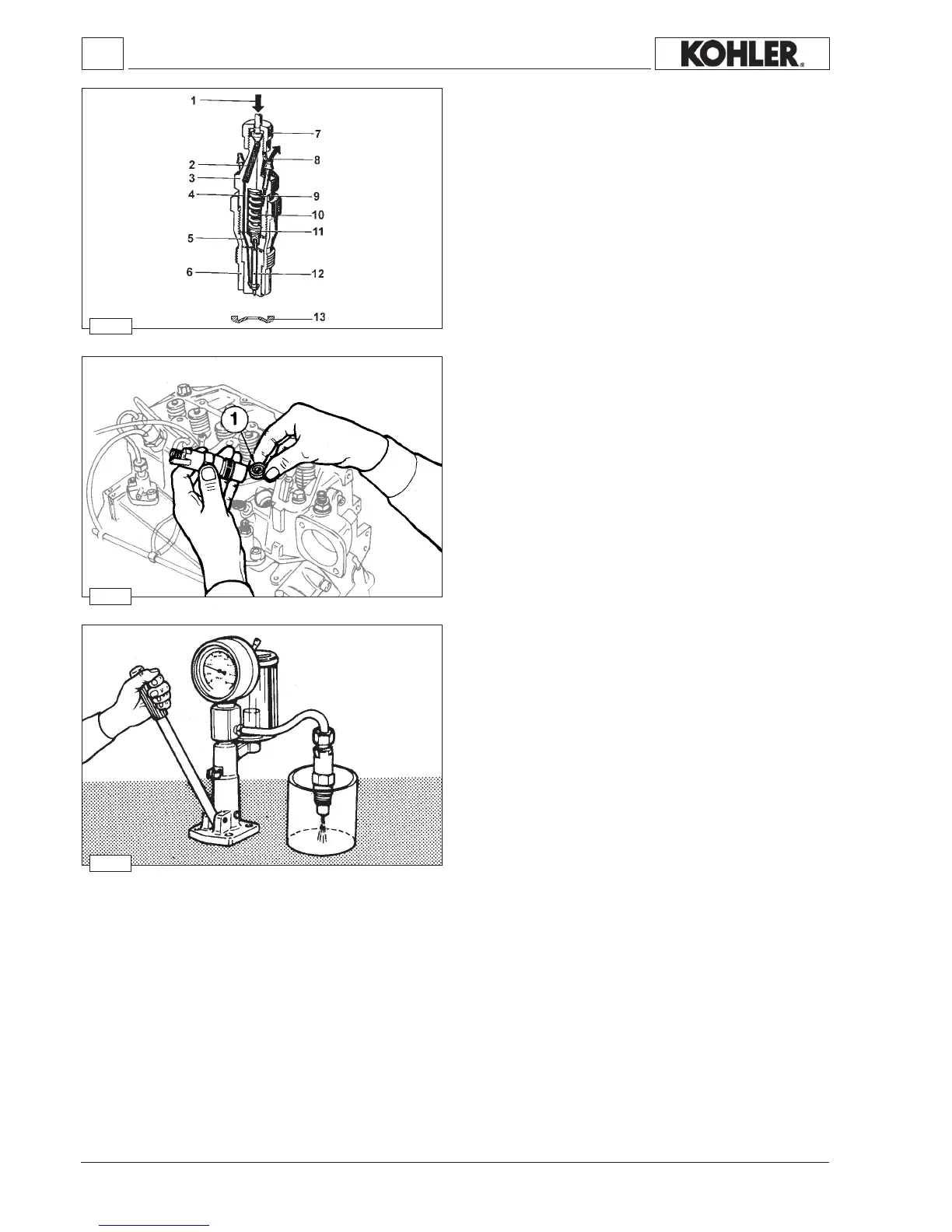

Injector setting

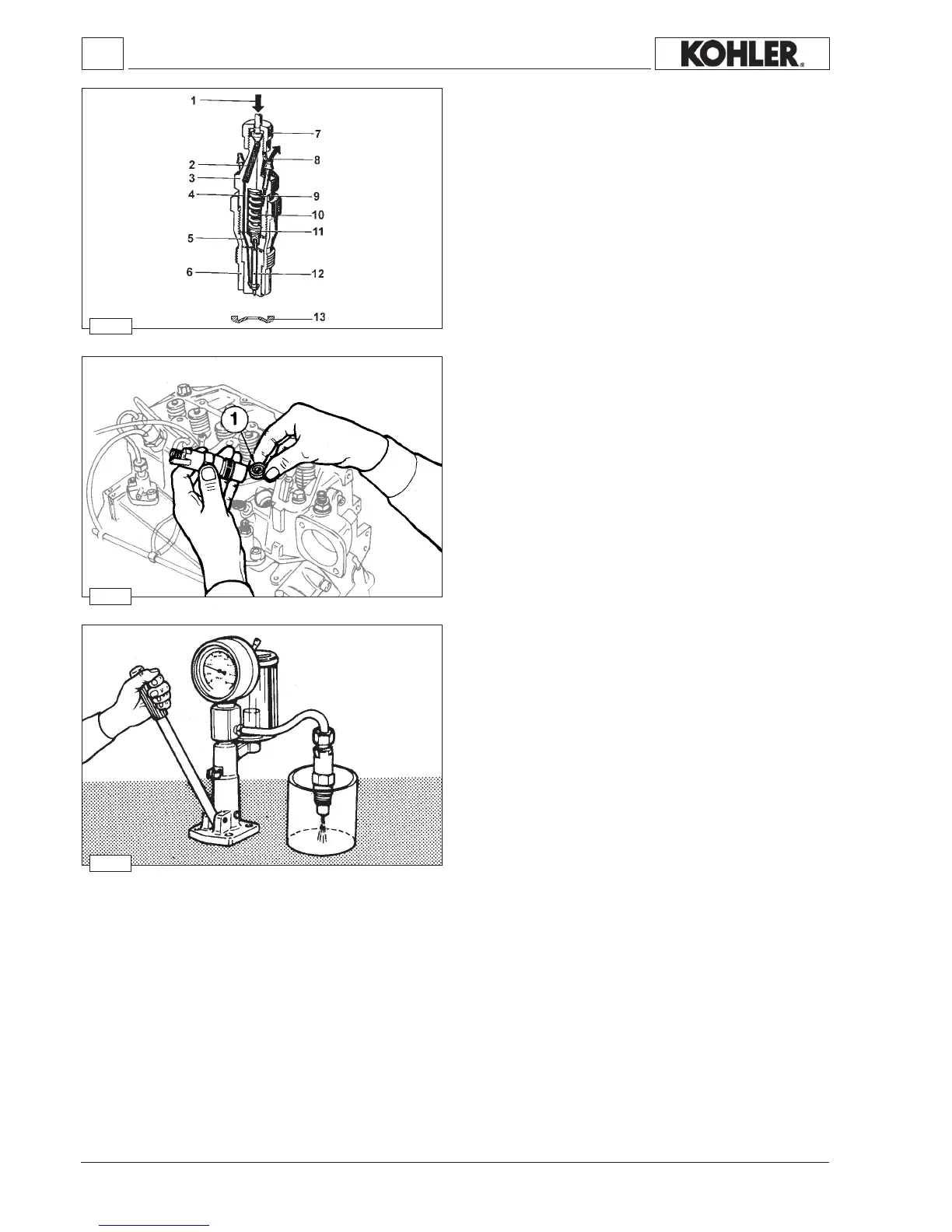

Connecttheinjectortoainjectionteststandandcheckthatthe

pressuresettingis140/150bar.

Addingtheshims9increasesthepressuresetting,reducingtheir

numberlowersit.

Eleven spare setting shims are included, their measurements

rangefrom1to2mm.

Whenspring10isreplaced,calibrationmustbecarriedoutata

pressure10barshigherthanthenominalpressure(160bar)to

counterbalancebeddingintheoperation.

Check needle valve sealing by slowly moving the hand pump

untilapproximately120barper10seconds.

Replacenozzle12incaseofdripping.

Thetorqueoftheinjectorringnutis70÷90Nm.

Whenever maintenance operations are carried out on the

injectorreplacethesealring1.

Introduce seal ring 1 into the injector housing with the sealing

surfacefacingupwards(seegure171).

Seepage22formaintenanceintervals.

Fixinjectortotheheadtighteningto70Nm.

Fuel system

Injector (pin type)

Components:

1

Fuelinlet 7Deliveryunion

2 Filter 8Backowunion

3Body 9Settingshims

4Deliveryduct 10Pressurespring

5Pad 11Pressurepin

6Clampingringnut 12Nozzle

13Fireproofbulkhead

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...