58

57

56

6

- 49 - - 49 -

KDW 1603

KDW 2204

2204/T

Disassembly / Reassembly

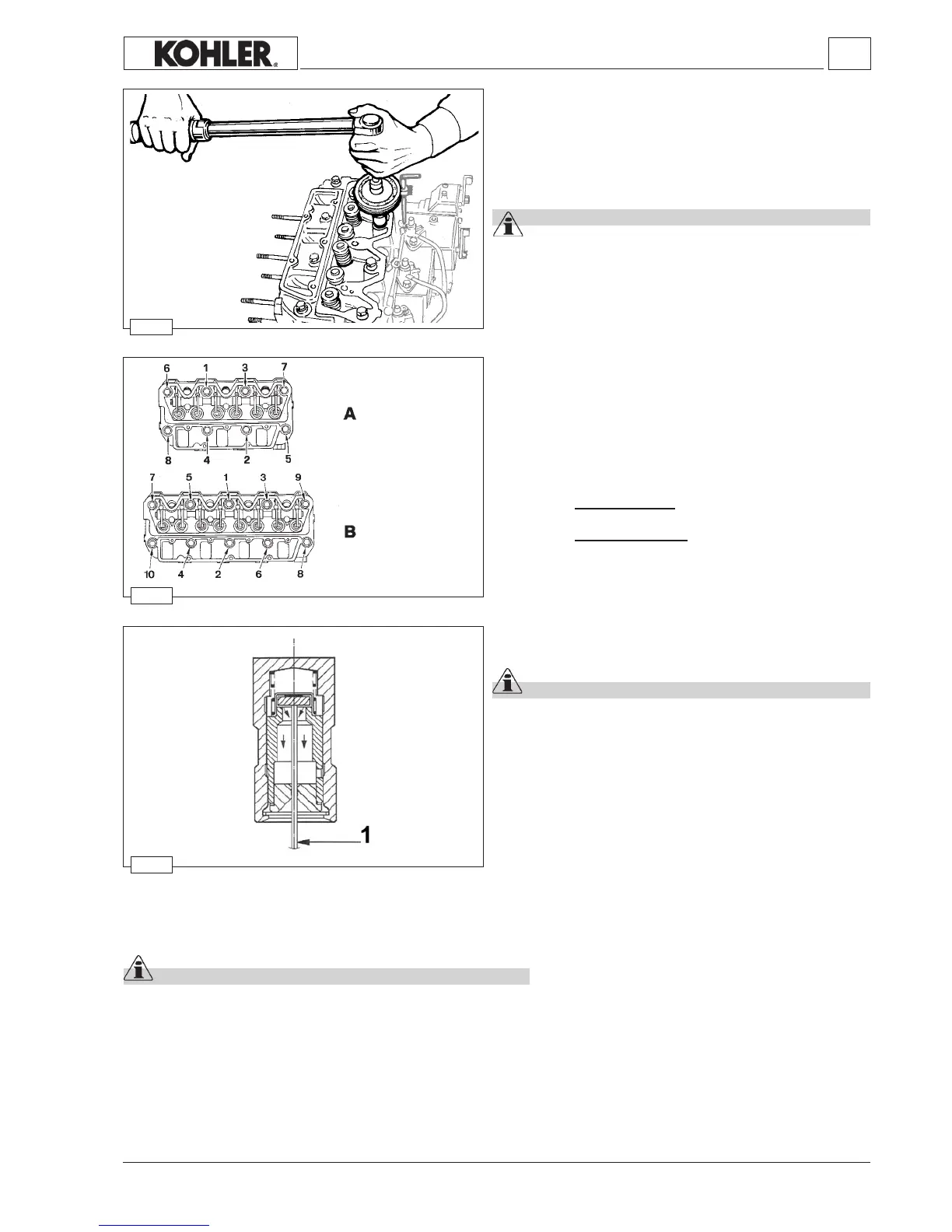

Cylinder head tightening for engines without hydraulic

tappets

Useatorquewrench(ttedwithtoolforangulartightening).

Itisrecommendedtoreplacethescrewswhenever theheadis

disassembled.

Important

The cylinder head must never be retightened.

It is advisable to lubricate the lower part of the screws with

anti-seize of the type MOLYSLIP AS COMPOUND 40.

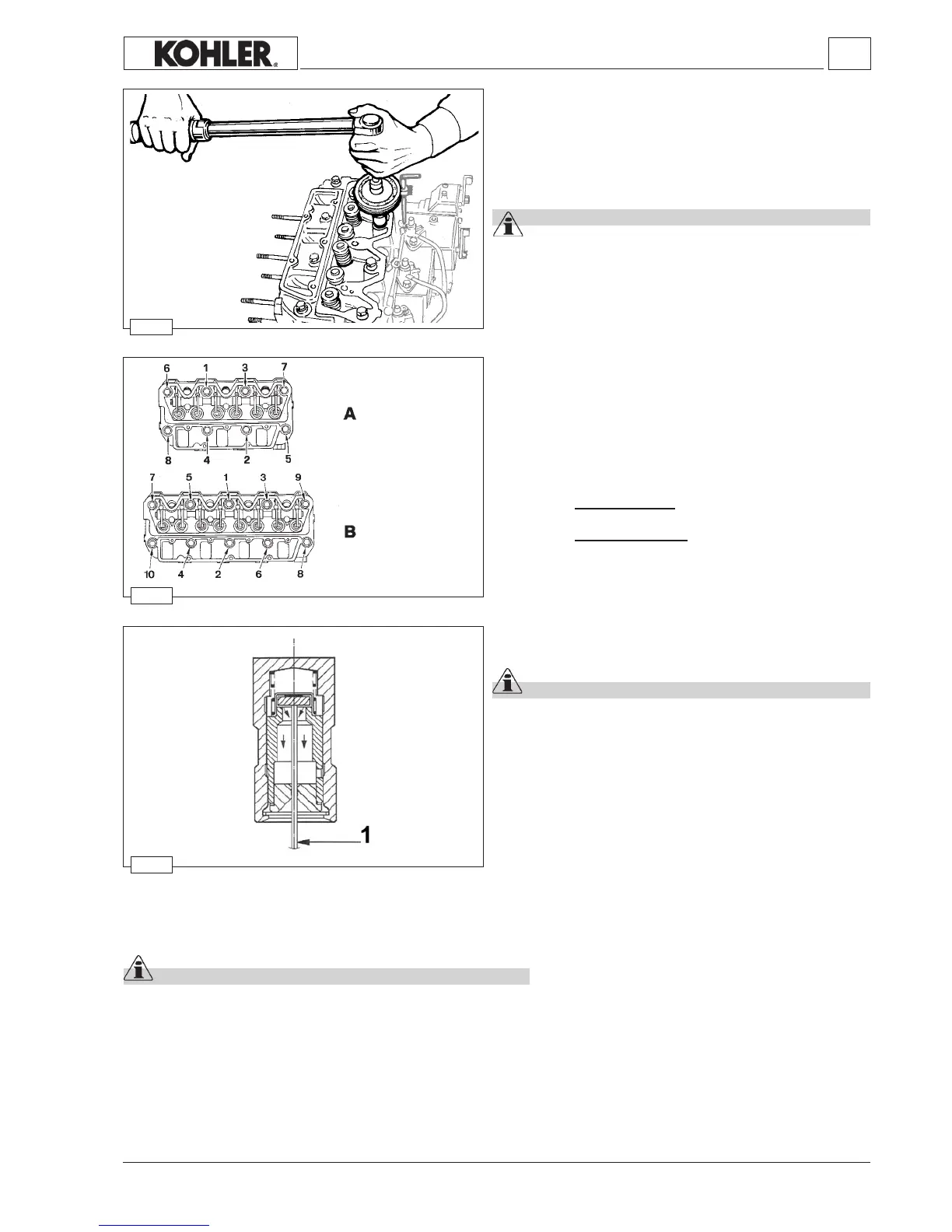

Cylinder head tightening steps

Following the number sequence shown in the gure 57 bolts

should be tightened in four susequent steps with the following

torquevalues:

1ststep=40Nm

2ndstep=70Nm

3rdstep=100Nm

4thsteps= For bolts 10 R: Rotate wrench by 180° (in two

steps90°+90°)

For bolts 12 R (present only in the TURBO

engines):performarotationofthekeyof270°(in

threesteps,90°+90°+90°).

Assembling and tightening the cylinder head on engines

with hydraulic tappets

Important

Before re-assembling the cylinder head the tappets must be

removed from their housing and released.

Thisoperationmustbecarriedoutusingapin1.

Insertpin1 insidethetappetandopenthenon-returnvalve.

Theexcessoilisreleasedbyturningthetappetupsidedown.

Rotatethecrankshaftsoastopositionthepistonsathalfstroke

forthree-cylinderengines.

Forfour-cylinderengines,placethepistonofcylindernumberone

at150°afterthetopdeadcentre(incrossoverstage).

Fitthehead,insertthefasteningscrewsandtightentheminthe

order shown in gure 57 and to their respective torques (see

“CylinderHeadTighteningStage).

Reassemblethecompletepininsertingtheseatsoftherocker-armsontheirrespectiverodsandscrewupthefasteningscrews

ofthesupportsbyhand.

Important

To avoid bending the push rods or damaging the tappets, the fastening screws of the rocker-arm pin supports must be

tightened gradually before reaching the nal torque.

Thisprocedurewillgivetimefortheexcessoilinthetappetstodrainaway.

Eachtimeyoustarttotightenupthefasteningscrewsofthesupports,youcanusetheupperspringsupportcupofthevalvespring

asanindicatortoknowhowfartoscrewthemup.

Thecupmustneverbecompressedsomuchthatittouchesthevalvestemoilsealingringttedontheguide.

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...