163

161

164

162

10

- 80 - - 80 -

Fuel system

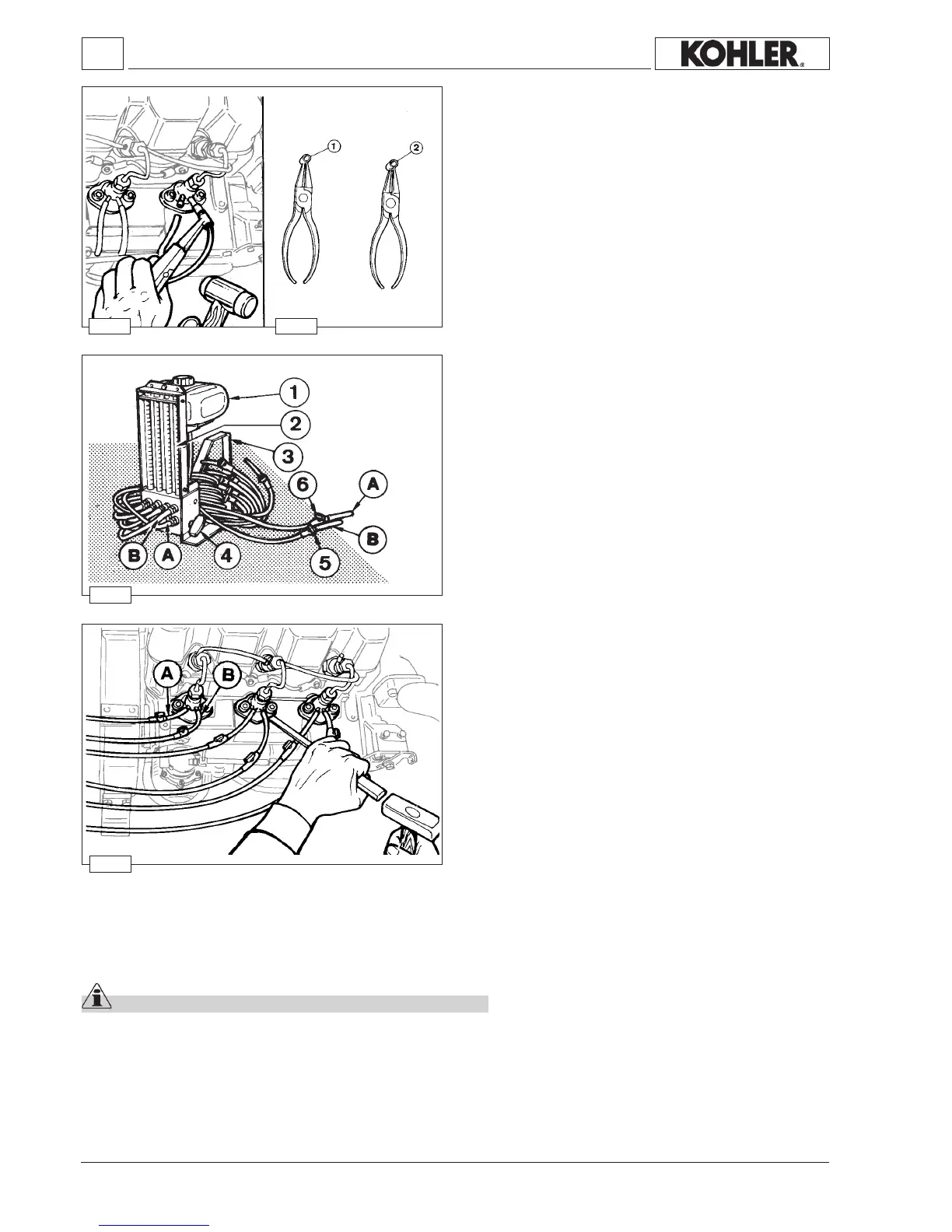

How to reassemble injection pump feeding tubes

1 Pliers for6 mmdiam. tubes (intake) -Part No. 7104-1460-

022

2

Pliers for 8 mm diam. tubes (discharge) - Part No. 7104-

1460-023

Feedinganddischargetubesaremadeofnylon;theytintothe

injection pump unions by exerting pressure and using special

pliersandaplastichammer.

Thenylontubescannolongerbeusedafterdisassembly.

Replacethemeverytimetheyareremoved.

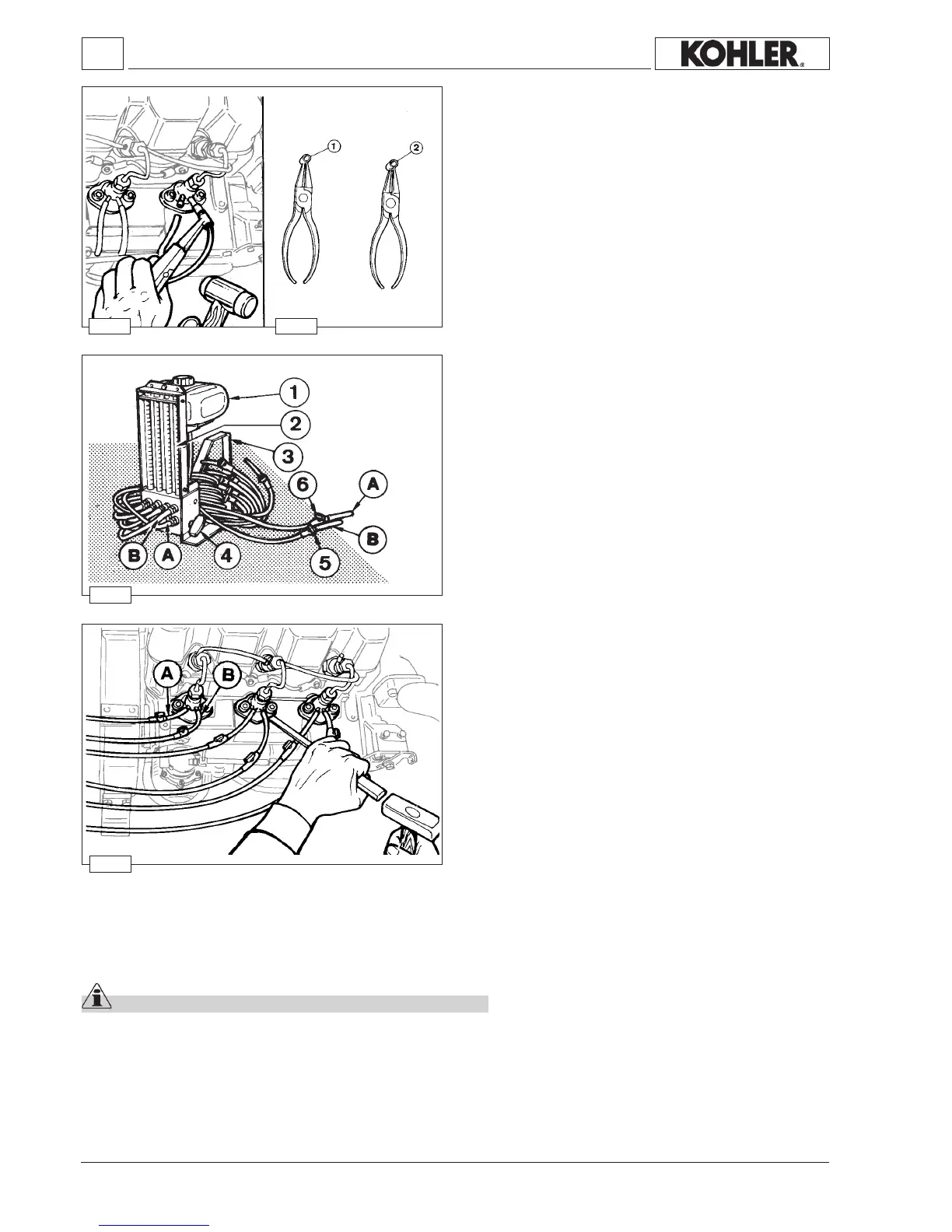

Instrument for equalizing injection pump delivery

Part No. 7104-1460-090

Components: 1 Tank 2Testtube

3Support 4 Switchinglever

5Injectionpumpdischargetubecut-offvalve

6Injectionpumpintaketube-offvalve

ATubeforconnectiontoinjectionpumpintakeunion

B Tubeforconnectiontoinjectionpumpdischargeunion

Removefeedtubesfromallinjectionpumpsandttheinstrument

tubes making sure that each pump has its own intake and

dischargetubes.ConnecttheinstrumentAwiththeengine Aand

theinstrument BwiththeengineB.Proceedinasimilarmanner

withtheotherpumps.

Injection pump delivery equalization

Aftercheckingtheinjectionadvancegoaheadwiththedelivery

balancingofthepumps.

Beforeconnecting the toolserialnumber 7104-1460-090 tothe

pumpsandrellingtank1withfuel,setittoahigherlevelofat

least200mmthanthatofthepumpsthemselves.

Opentaps5 and6 andstarttheengine,settheenginetoanidling

speedof2000rpm.Switchtheenginefeedfromtank 1 tothetubes

2 usingtheswitchinglever 4g.163.

Aftertherstminute(minimumtestingtime),verifythatthelevel

betweenthehighest and lowestlevels inthe tubesis notmore

than2cm³.

At this point, it is possible to either reduce the delivery of the

pumpthatconsumesmost(tubewiththelowestlevel)orincrease

thedeliveryofthepumpthatconsumestheleast(tubewiththe

highestlevel).

Tovarythedeliveryofthepumps,rotateslightlyinonedirectionortheotherattheinjectionpumps.

Unscrewthefasteningscrewsofthepumptobeadjustedbyaquarterofaturn.

Rotatingclockwisethedeliveryisincreased,anti-clockwisethedeliveryisreduced.

Onceadjustmentisnished,tightenthefasteningscrewsto25Nm.

Important

Whenever an injection pump is disassembled or replaced, delivery balancing must be carried out.

Note: A referencenotch islocated between thepump angeand itsmounting onthe crankcase. Ifone ormore pumpsare

disassembledandreassembleddoasfollows:

- Makeareferencemarkingonthefasteningangesoftheinjectionpumpsandonthebaseplanesofthecrankcase.

- Leavetheshimsforinjectiontimingsettingundereachpumpunchanged.

- Eachpumpshouldbereassembledinitsownhousing.

Alignthedeliveryreferencenotcheslocatedonthepumpangewiththoseonthecrankcase.

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...