Maintenance

W9215-8135-1 145

06/2021

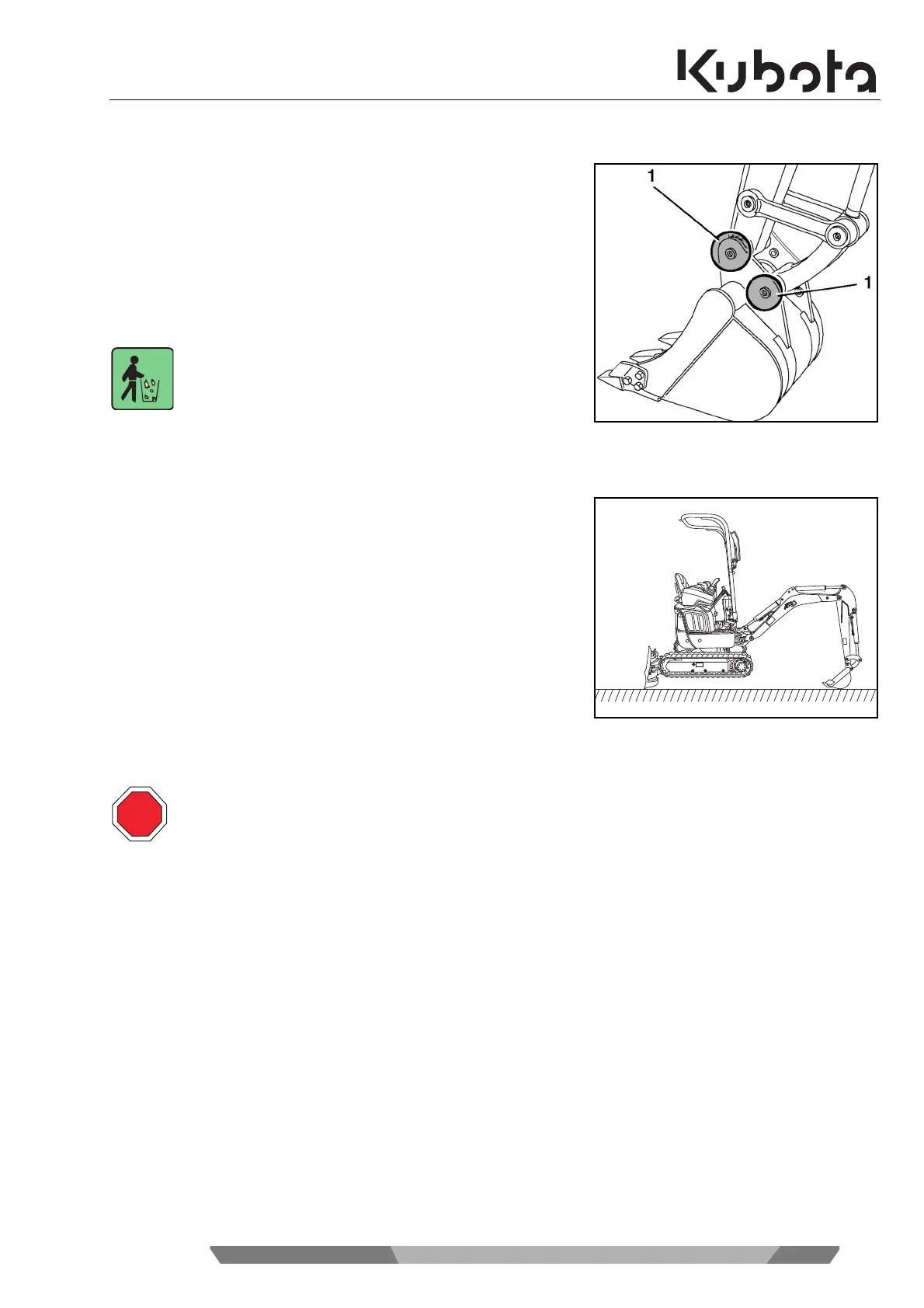

Bucket bolts - grease

Start the engine (page 78).

Position the bucket as illustrated. Lock the control lever, stop

the engine and remove the key. See the "

Operating the con-

trols during excavation work" section (page 91).

Lubricate all grease points (1) with grease until fresh grease

emerges. See the "

Recommended lubricants" section

(page 130).

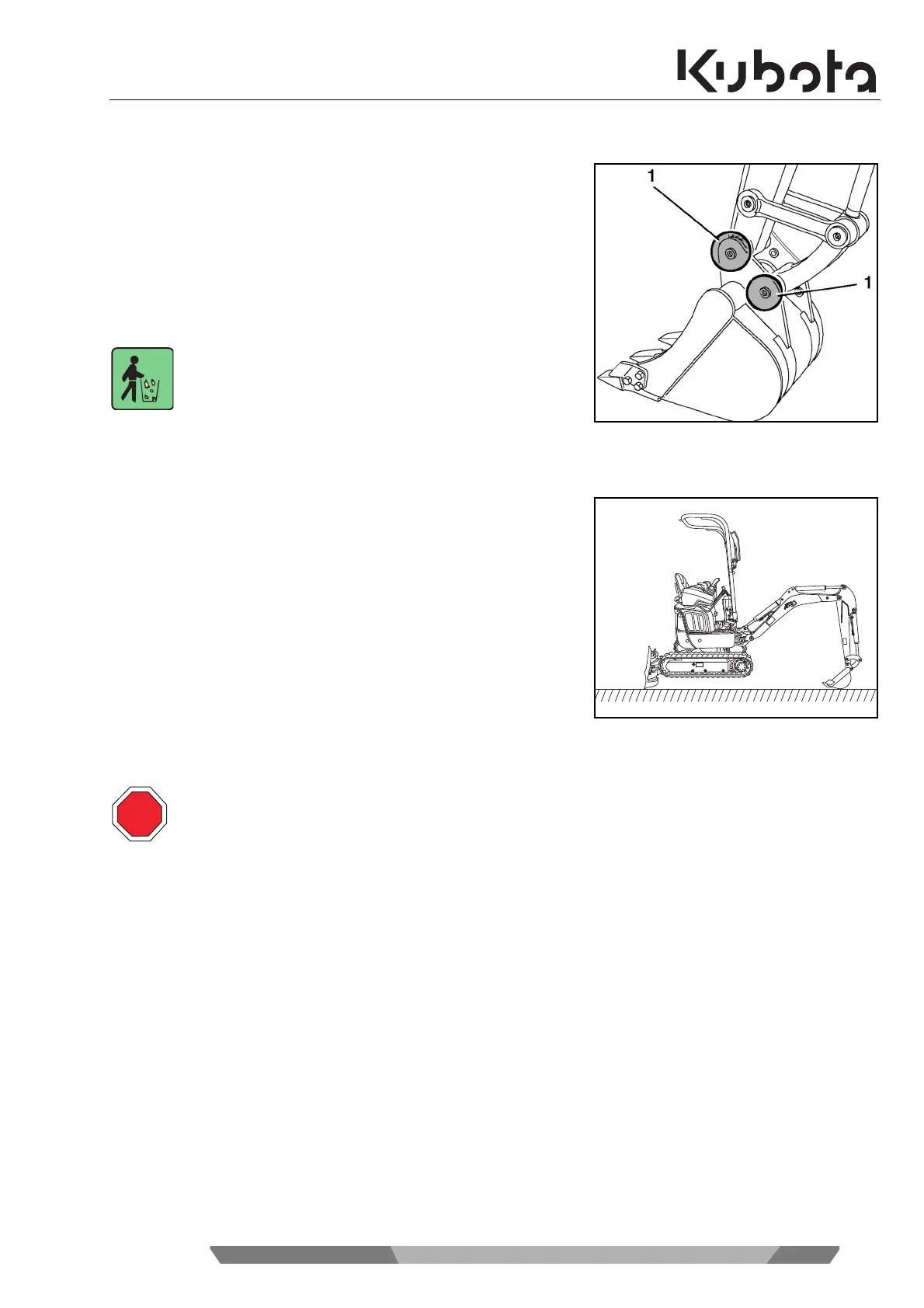

Crawler tension - check/adjust

When parking an excavator with rubber crawlers, ensure that the

seam ( ) is on top, half way between the two sliders (see figure/1,

"Crawler tension - check", page 146).

Clean all parts of the running gear, paying particular attention

to stones between the crawler and sprocket or idler. Clean the

area of the crawler tensioning cylinder.

Swivel the swivel frame 90° to the direction of travel as shown

in the figure.

Lower the front attachments on the ground and raise the exca-

vator approx. 200 mm off the ground on one side.

Support the excavator with appropriate backing material, observing the vehicle weight.

Wipe emerged grease off immediately and store dirty

cleaning cloths in the containers provided for disposal.

Working under the lifted excavator poses a danger!

For your own safety, do not use any hydraulic supports. They can lower due to loss of pressure, tip

over or be lowered by mistake.

- Never work under the lifted excavator.

- Do not work with hydraulic supports.

- Have a guide supervise the procedure.

Loading...

Loading...