ENGINE

L3540-II, L4240-II, L5040-II, L5240-II, L5740-II , WSM

1-S72

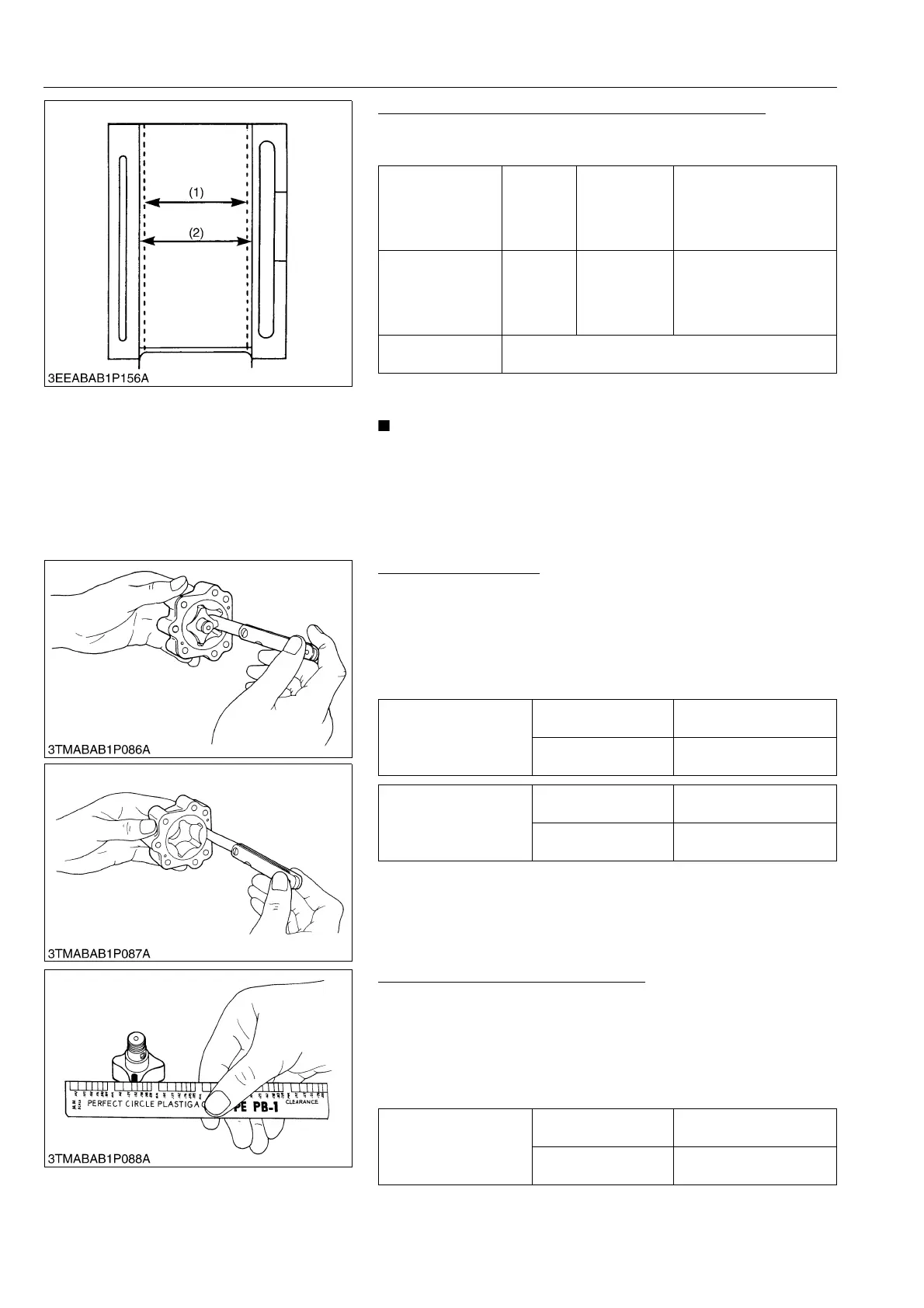

Correcting Cylinder (Oversize +0.25 mm, +0.0098 in.)

1. When the cylinder is worn beyond the allowable limit, bore and

hone it to the specified dimension.

2. Replace the piston and piston rings with oversize (+0.25 mm,

+0.0098 in.) ones.

• When the oversize cylinder is worn beyond the allowable

limit, replace the cylinder block with a new one.

9Y1211167ENS0095US0

[6] OIL PUMP

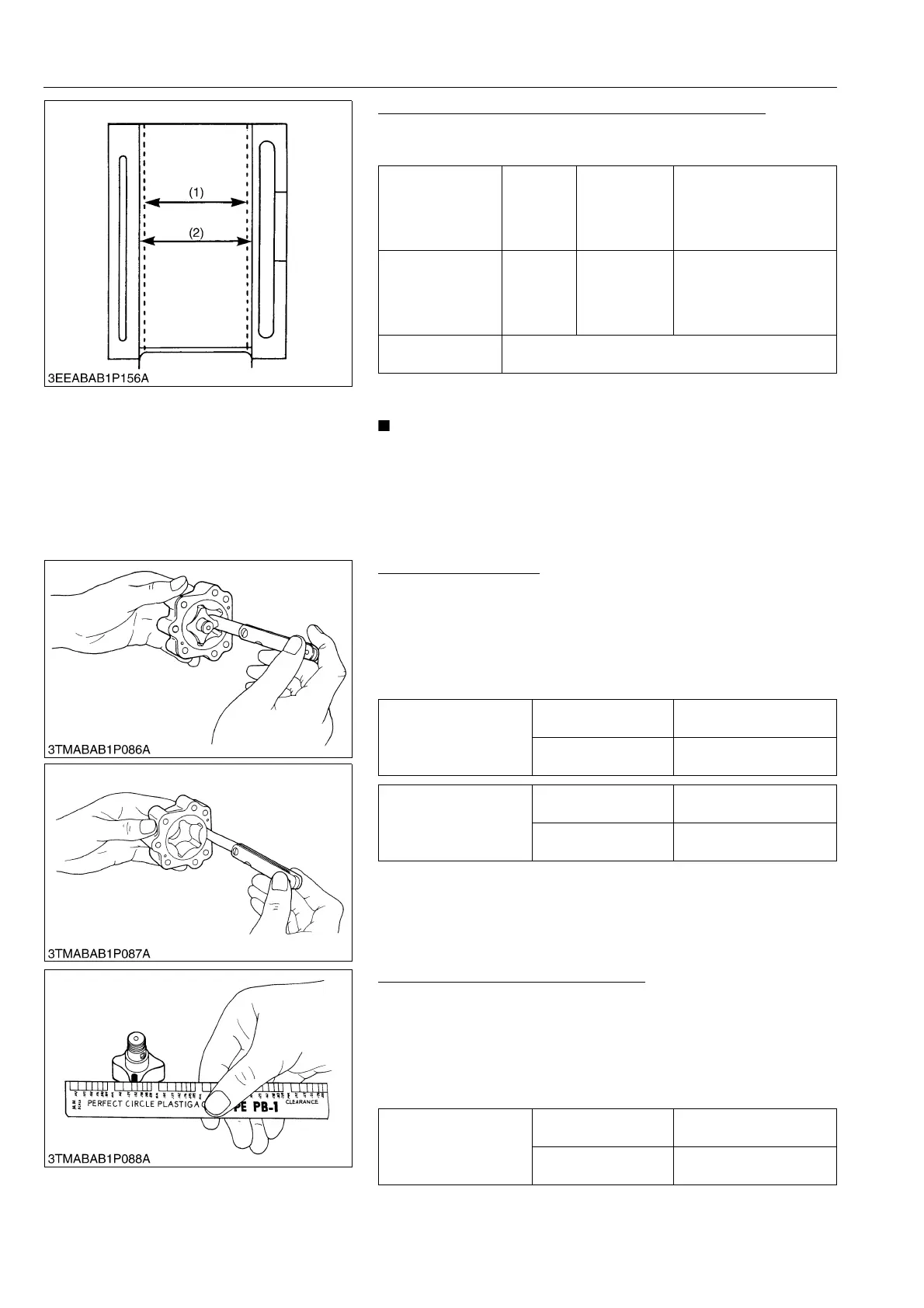

Rotor Lobe Clearance

1. Measure the clearance between lobes of the inner rotor and the

outer rotor with a feeler gauge.

2. Measure the clearance between the outer rotor and the pump

body with a feeler gauge.

3. If the clearance exceeds the factory specifications, replace the

oil pump rotor assembly.

9Y1211167ENS0096US0

Clearance between Rotor and Cover

1. Put a strip of plastigage onto the rotor face with grease.

2. Install the cover and tighten the screws.

3. Remove the cover carefully, and measure the width of the press

gauge with a sheet of gauge.

4. If the clearance exceeds the factory specifications, replace oil

pump rotor assembly.

9Y1211167ENS0097US0

Oversize cylinder

I.D.

Factory

specifica-

tion

D1703-M,

D1803-M,

V2203-M,

V2403-M,

V2403-M-T

87.250 to 87.272 mm

3.4351 to 3.4359 in.

Maximum wear

Allowable

limit

D1703-M,

D1803-M,

V2203-M,

V2403-M,

V2403-M-T

+0.15 mm

+0.0059 in.

Finishing

Honing to 2.20 to 3.00 mm μR max.

(0.0867 to 0.118 in. μR max.)

(1) Cylinder I.D. (Before Correction) (2) Oversize Cylinder I.D.

Clearance between inner

rotor and outer rotor

Factory specification

0.030 to 0.14 mm

0.0012 to 0.0055 in.

Allowable limit

0.20 mm

0.0079 in.

Clearance between outer

rotor and pump body

Factory specification

0.11 to 0.19 mm

0.0044 to 0.0074 in.

Allowable limit

0.25 mm

0.0098 in.

Clearance between inner

rotor and cover

Factory specification

0.105 to 0.150 mm

0.00414 to 0.00590 in.

Allowable limit

0.20 mm

0.0079 in.

Loading...

Loading...