HYDRAULIC SYSTEM

L3540-II, L4240-II, L5040-II, L5240-II, L5740-II , WSM

8-S14

5. DISASSEMBLING AND ASSEMBLING

[1] HYDRAULIC PUMP

• The hydraulic pump is precision machined and assembled: if disassemble once, it may be unable to keep

its original performance. Therefore, when the hydraulic pump fails, replacement should be carried out

with the hydraulic pump assembled except when emergency repair is unavoidable.

• When repair is required, follow the disassembly and servicing procedures shown below with utmost care.

• Be sure to test the hydraulic pump with a flowmeter before disassembling.

• After reassembly, be sure to perform break-in operation and ensure that there is nothing abnormal with

the hydraulic pump.

9Y1211167HYS0011US0

(1) Removing Hydraulic Pump Assembly

Bonnet and Side Skirt RH

1. Open the bonnet (1).

2. Remove the side skirt RH (2).

9Y1211167HYS0012US0

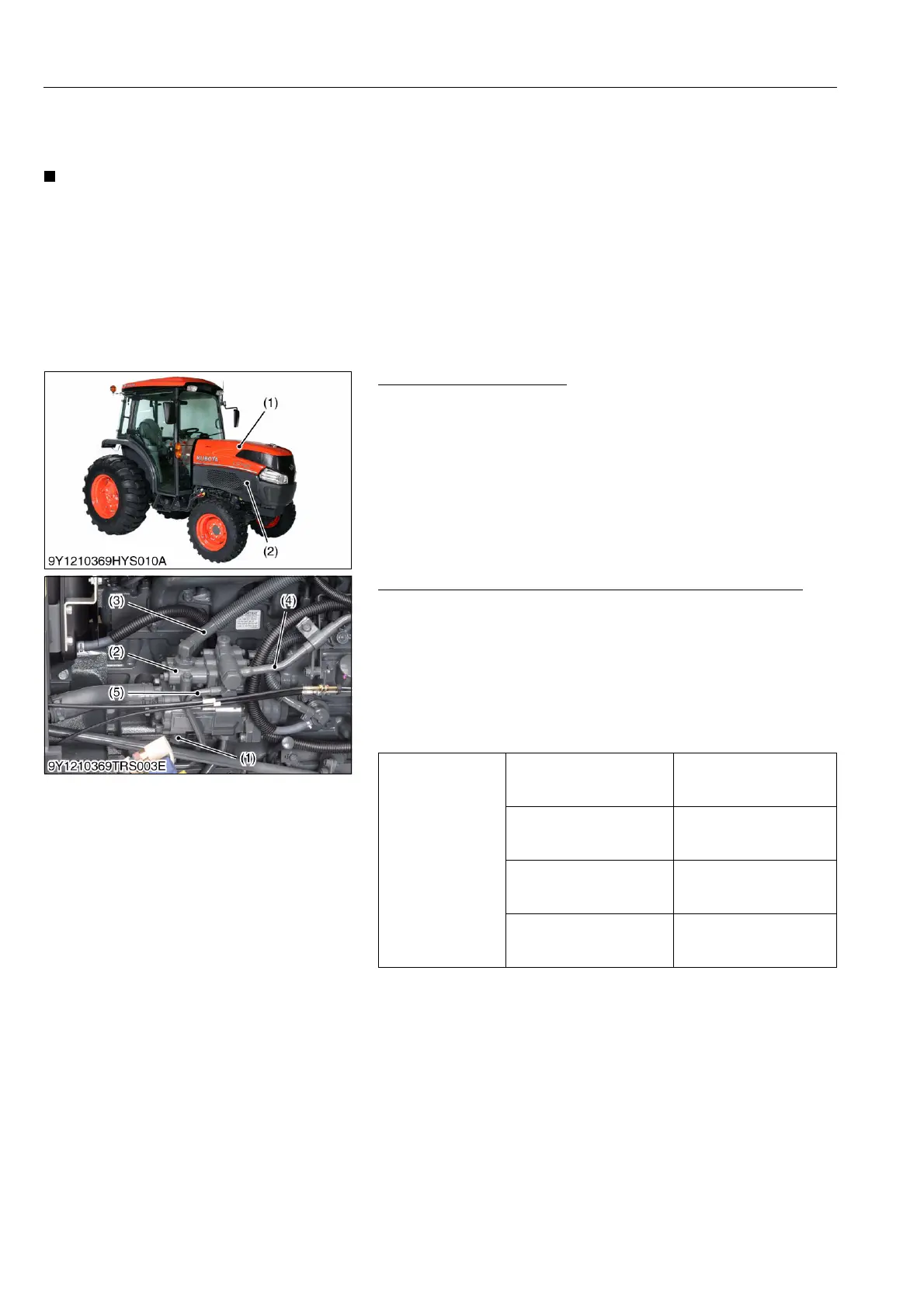

Regulating Valve (Manual Transmission and GST Models)

1. Disconnect the power steering delivery pipe (4) and return hose

(3).

2. Disconnect the GST/PTO delivery pipe (5) and regulator

delivery pipe (1).

3. Remove the regulating valve (2).

(When reassembling)

• Apply grease to the O-ring and be careful not to damage it.

• Install the copper washers firmly.

9Y1211167HYS0013US0

(1) Bonnet (2) Side Skirt RH

Tightening torque

Power steering delivery

pipe joint bolt

40 to 49 N·m

4.0 to 5.0 kgf·m

29 to 36 lbf·ft

GST/PTO delivery pipe

joint bolt

35 to 39 N·m

3.5 to 4.0 kgf·m

26 to 28 lbf·ft

Regulator delivery pipe

joint bolt

40 to 49 N·m

4.0 to 5.0 kgf·m

29 to 36 lbf·ft

Regulating valve mounting

screw

18 to 20 N·m

1.8 to 2.1 kgf·m

13 to 15 lbf·ft

(1) Regulator Delivery Pipe

(2) Regulating Valve

(3) Return Hose

(4) Power Steering Delivery Pipe

(5) GST/PTO Delivery Pipe

Loading...

Loading...