CANopen

4 Installation

4-5

L BA2175 EN 2.0

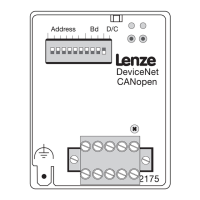

4.4 Structure of a CAN bus system (Example)

The CAN bus system is designed as 2 conductor type (twisted pair) shielded with additional mass

and termination at both ends of the line (see

(^ 4-6) ).

Data can be send and received as follows:

• Max. 3 process data channels (PDO = Process Data Object)

– Process data are send via the process data channel and are used for high-speed and

high-priority control tasks. Typical process data are, for instance, setpoints and actual

values for a controller.

• 2 parameter data channels(SDO = Service Data Object)

– Parameters are transferred at lower priority than process data. Parameters are set or

changed during, for instance, commissioning or changing the product.

– Parameters are accessed via the parameter data channel of the 2175 fieldbus module to

the Lenze controller codes or corresponding CANopen objects (detailed description in

chapter CANopen parameter setting).

– 2 masters can be connected to the controllers because of the 2 parameter channels. Thus,

parameters can be changed directly at the controller during operation of a machine or

system networked via PLC, using a PC (e.g. with the user software Global Drive Control) or

a keypad. The second parameter data channel can be accessed with an offset of 64 via the

address set (switch or L-C0009). For instance, if a PLC addresses the controller with

address 1 and a second commanding unit address 65, the same controller will be

addressed. Please note that the last telegram determines a parameter when it is accessed

by two units ( see “Server SDO Parameters”

(^ 6-35) ).

Note!

Please note that the last telegram determines a parameter when it is accessed by two units.

See chapter 5, if you do not use the front switch to enter baud rate and address.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.actechdrives.com - Email: info@actechdrives.com

Loading...

Loading...