11-9

11

Inspection and Adjustment of Valve Clearance

Service standards Unit : mm {in.}

Location Maintenance item Standard value Limit Remedy

— Valve clearance (When engine is cold) 0.4 {0.016} — Adjust

12406

Inspect and adjust the valve clearance while the engine is cold in the

following way.

[Inspection]

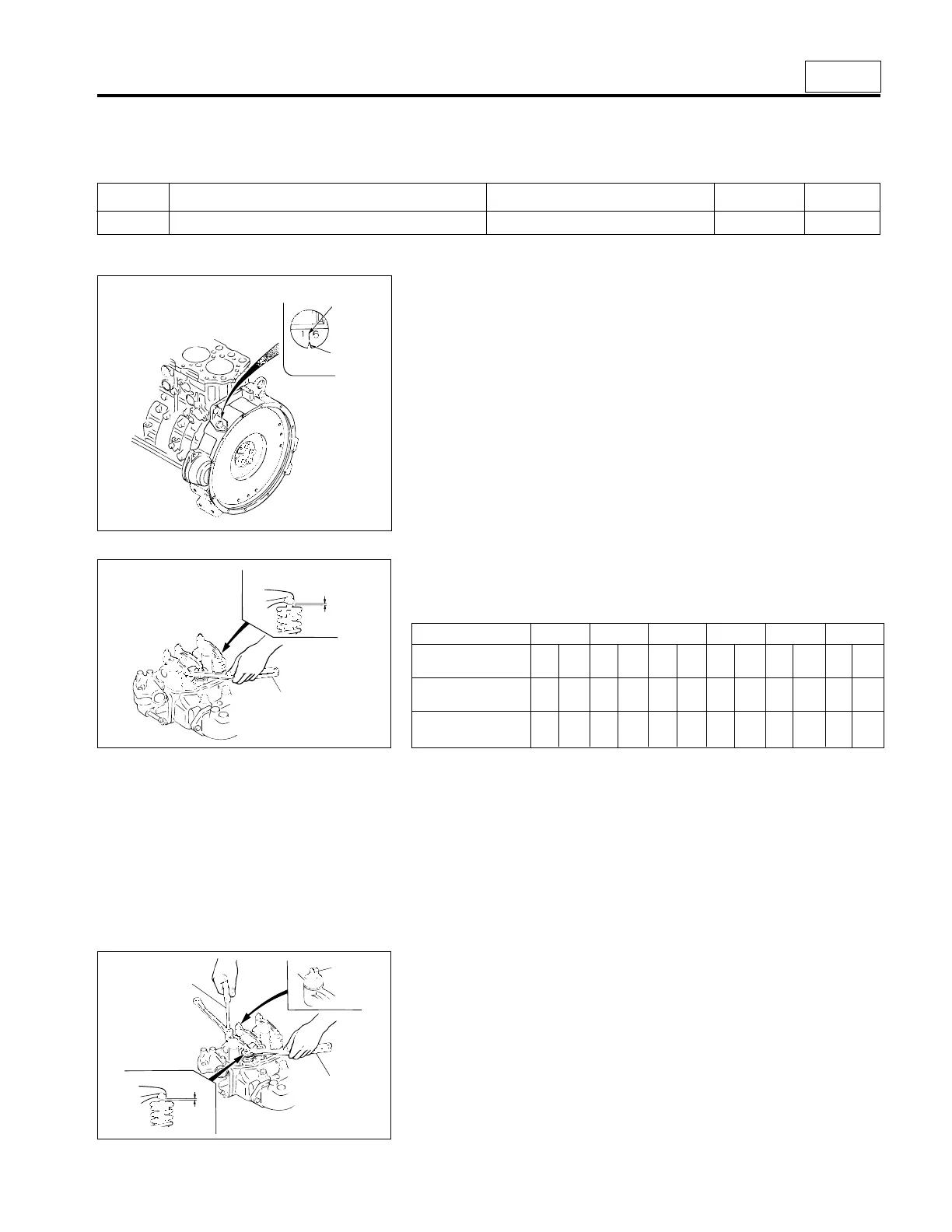

• Crank the engine to move No.1 or No.6 piston to top dead center, and

align stamped marks “1, 6” on the flywheel with pointer 1 on the

flywheel housing.

NOTE

The cylinder whose push rod is not pushing up the inlet/outlet

rocker is the one whose piston is at top dead center.

“1, 6”

1

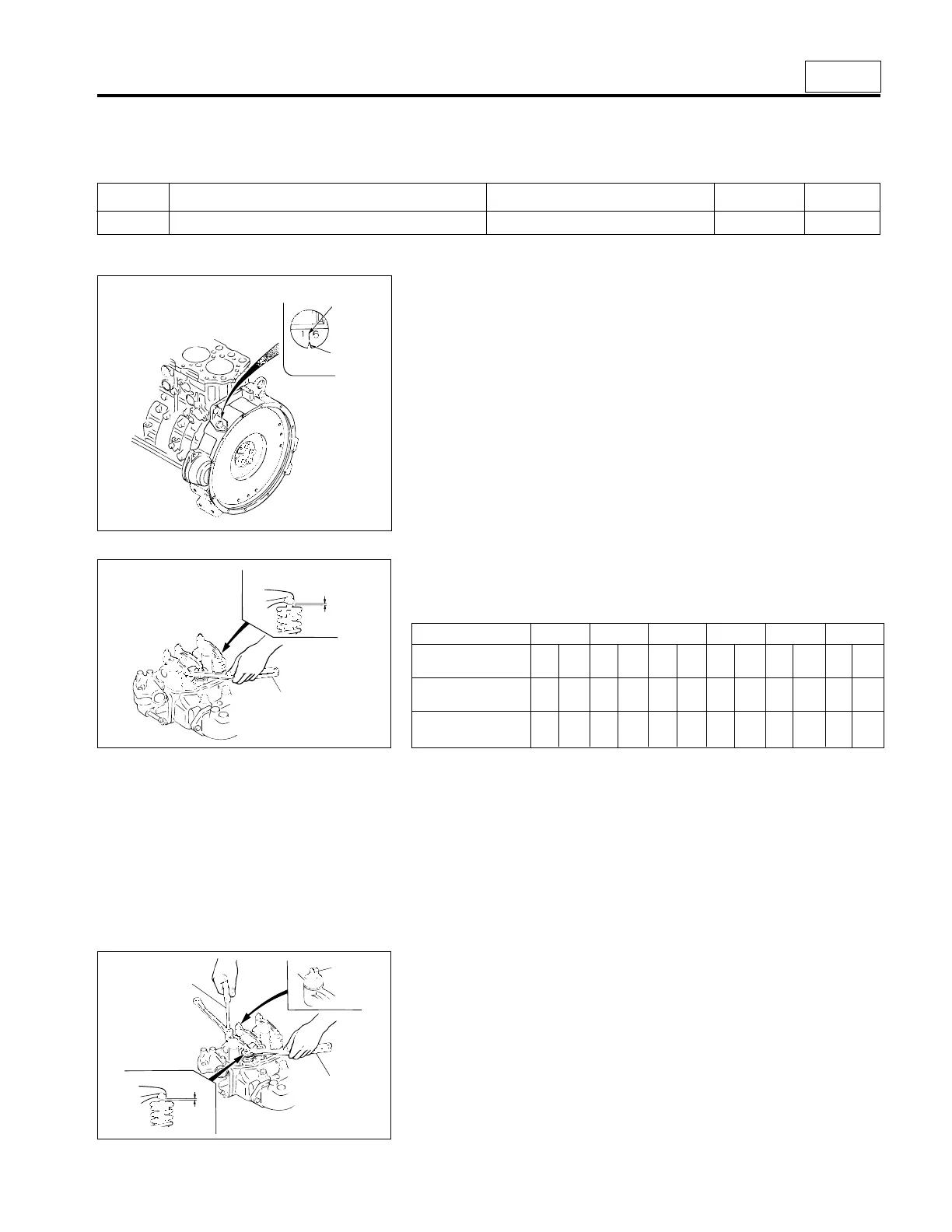

• Measure valve clearance A when either No.1 or No.6 piston is at top

dead center in accordance with the following tabulated sequence of

each valve.

06205

A

2

Piston No. 1 2 3 4 5 6

Valve In- Ex- In- Ex- In- Ex- In- Ex- In- Ex- In- Ex-

arrangement take haust take haust take haust take haust take haust take haust

No.1 piston at top

dead center ● ● ● ✕✕● ● ✕✕● ✕✕

No.6 piston at top

dead center ✕✕✕● ● ✕✕● ● ✕ ● ●

NOTE

Be sure when taking measurements using feeler gauge 2 that

some resistance is felt when inserting the gauge. If the gauge can

be inserted freely without any resistance, an accurate measure-

ment cannot be obtained.

• If the measured value deviates from the limit, adjust as follows:

06206

5

4

2

3

A

[Adjustment]

• Adjust valve clearance A so that feeler gauge 2 encounters some

resistance when it is inserted. Do this by loosening lock nut 3 and

turning adjusting screw 4.

• After adjusting, tighten adjusting screw 4 using screwdriver 5 and

tighten lock nut 3. Reinspect valve clearance A using feeler gauge 2.

Loading...

Loading...