01-12

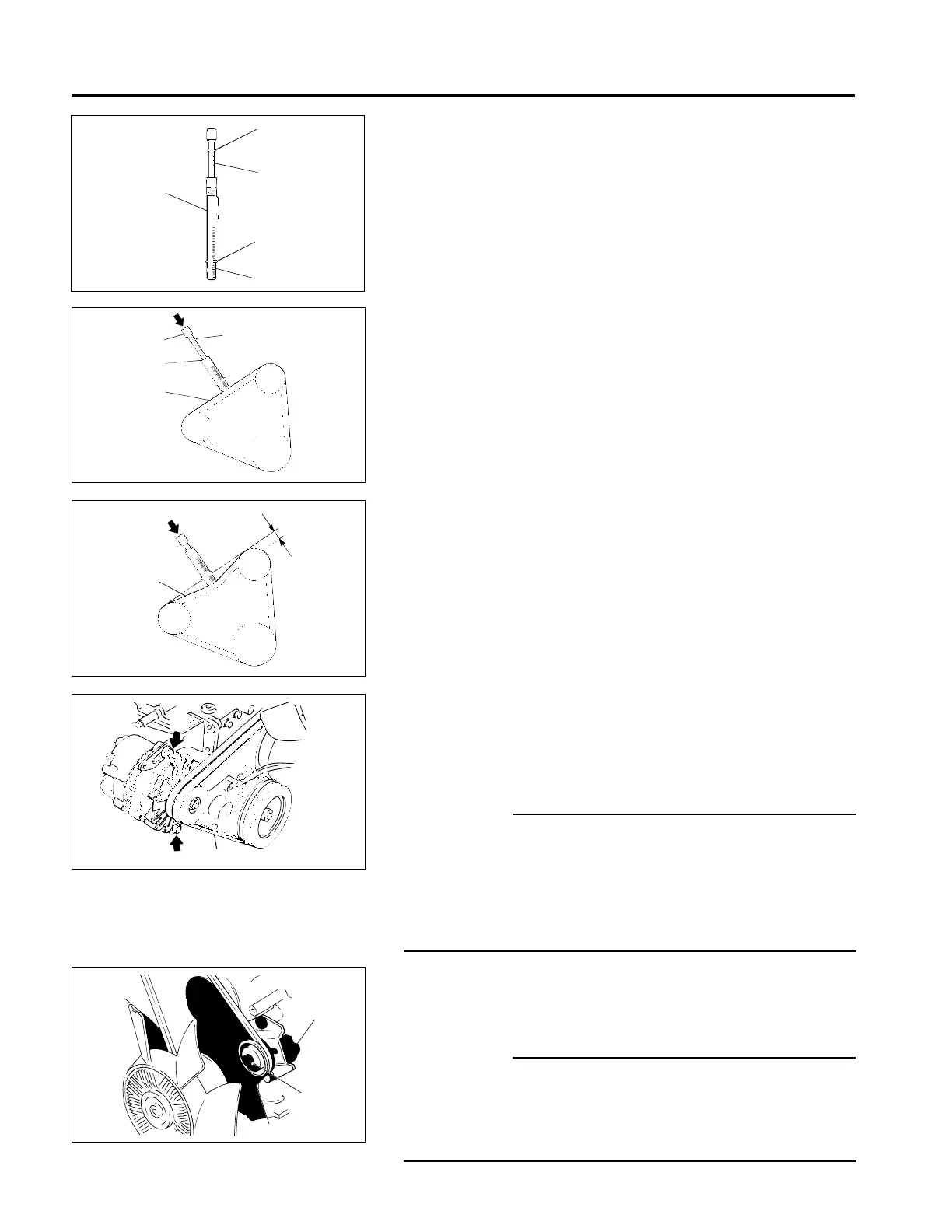

Use of special tool belt tension gauge

• Set upper O-ring G of 0 belt tension gauge to 98 N·m {72 lbf.ft,

10 kgf·m} (push load) on graduation H.

• Set lower O-ring J of 0 belt tension gauge to graduation K (maximum

flex of belt).

03613

MAINTENANCE OPERATIONS

03614

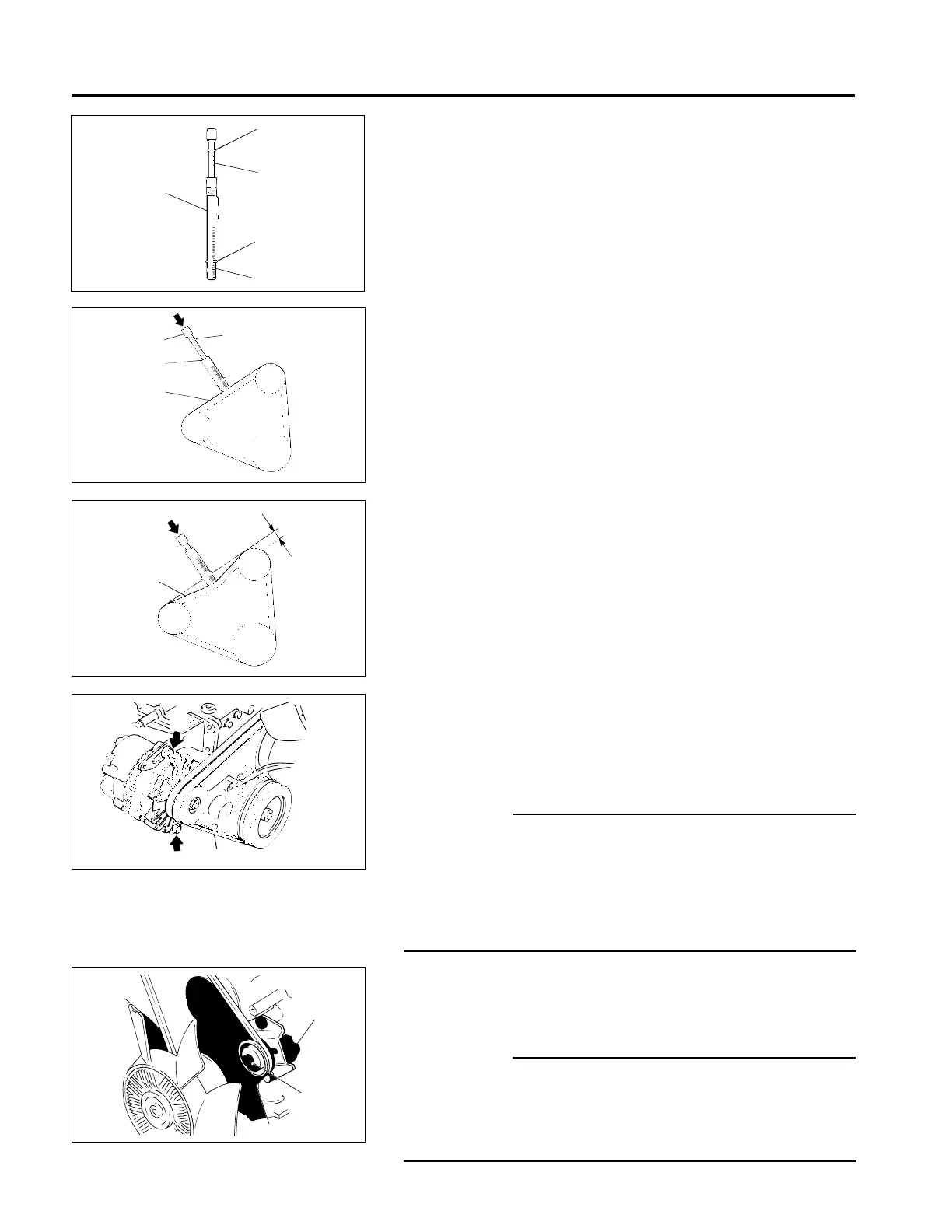

• Place 0 belt tension gauge at the center of V-belts 1, 2 perpendicu-

larly as illustrated and push top L all the way down until upper O-ring

G hits upper edge M.

03615

• Measure the extent of flex A of V-belts 1, 2 at this point, and if the

measured value deviates from the standard value, adjust as follows:

11519

[Adjustment]

(1) Adjustment of tension of V-belt for fan

• Loosen alternator mounting bolts N (two points), and adjust the

tension of V-belts 2 by moving adjusting bolt P.

• After adjustment, tighten the bolts N, P securely.

CAUTION–

• Bear in mind that excessive tension of V-belts 2 might damage

the belts and bearings that engage with the V-belts.

• Be sure to replace V-belts 2 as a set to maintain even tension

between them.

• Be careful not to let oil stick to V-belts 2. If oil gets onto the

belts, it causes slipping, resulting in overheating and insuffi-

cient battery charging.

(2) Adjustment of tension of V-belt for air-conditioner

• Loosen tension pulley mounting nut Q, and adjust the tension of

V-belt 1 moving adjusting bolt R.

• After adjustment, tighten mounting nut Q securely.

CAUTION–

• Bear in mind that excessive tension of V-belt 1 might damage

the belt and bearings that engage with the V-belt.

• Be careful not to let oil stick to V-belt 1. If oil gets onto the belt,

it causes slipping, resulting in poor performance of the air

conditioner.

11520

N

2

A

1, 2

1, 2

M

L

G

K

J

0

G

H

P

1

Q

R

Loading...

Loading...