11-23

11

03257

[Installation]

• Make sure that the diameter of valve seat hole of cylinder head 23

conforms to the standard value.

E : Inlet valve seat hole diameter

F : Exhaust valve seat hole diameter

S

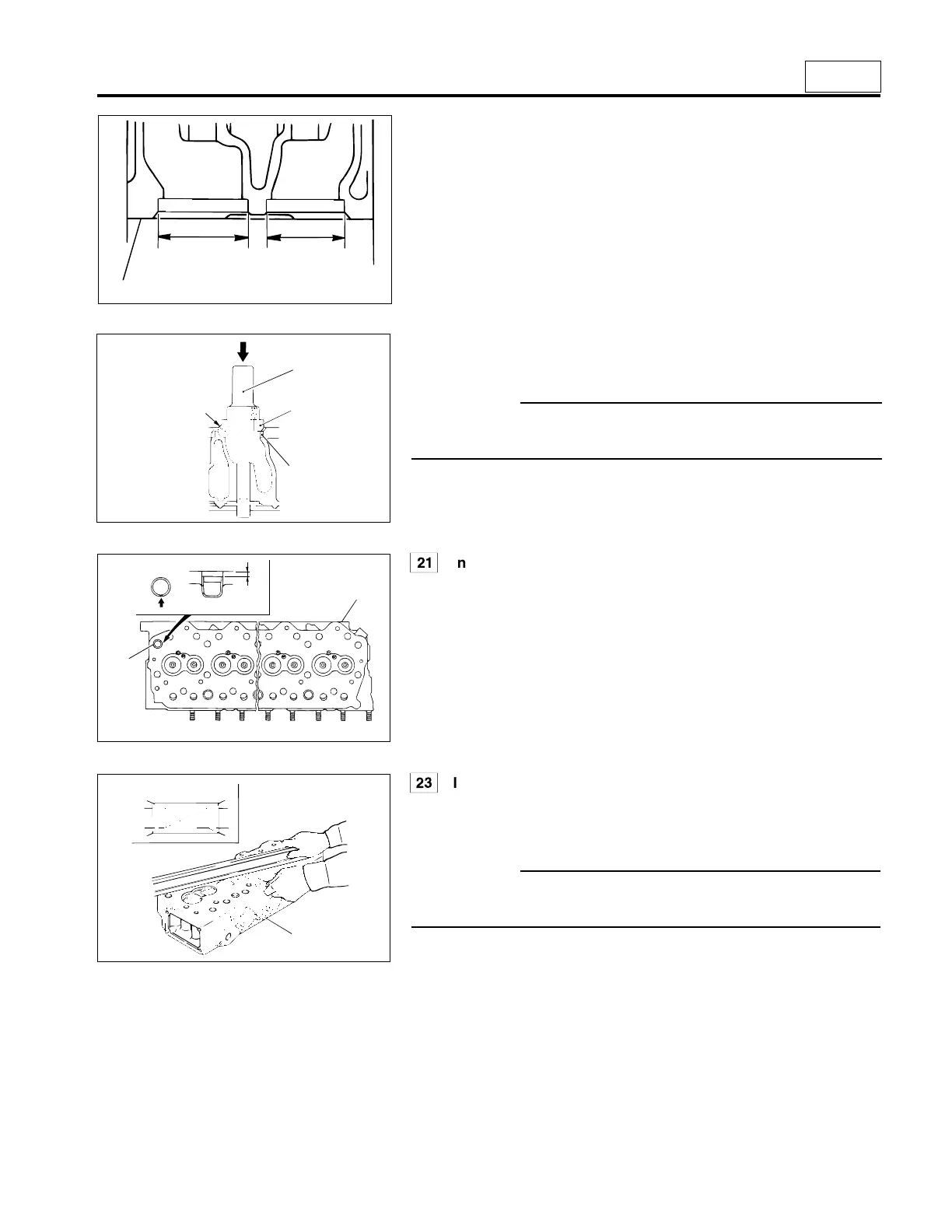

Inspection of cylinder head

Measure the extent of distortion of the bottom of cylinder head 23, and if

the measured value is higher than the standard value, grind using a

surface grinder.

CAUTION–

Be sure to keep the amount of grinding within the limit of the

height of cylinder head 23.

08400

12439

03262

• Immerse valve seats 19, 20 in liquid nitrogen and cool them substan-

tially. Press-fit into the cylinder head using 1 caulking tool body and

2 caulking rings inlet and exhaust.

CAUTION–

Be sure, when press-fitting, to place the chamfered side G of 2

caulking rings inlet and exhaust against valve seats 19, 20.

• After installation of valve seats 19, 20, work until they contact valves 7,

8 smoothly.

Q

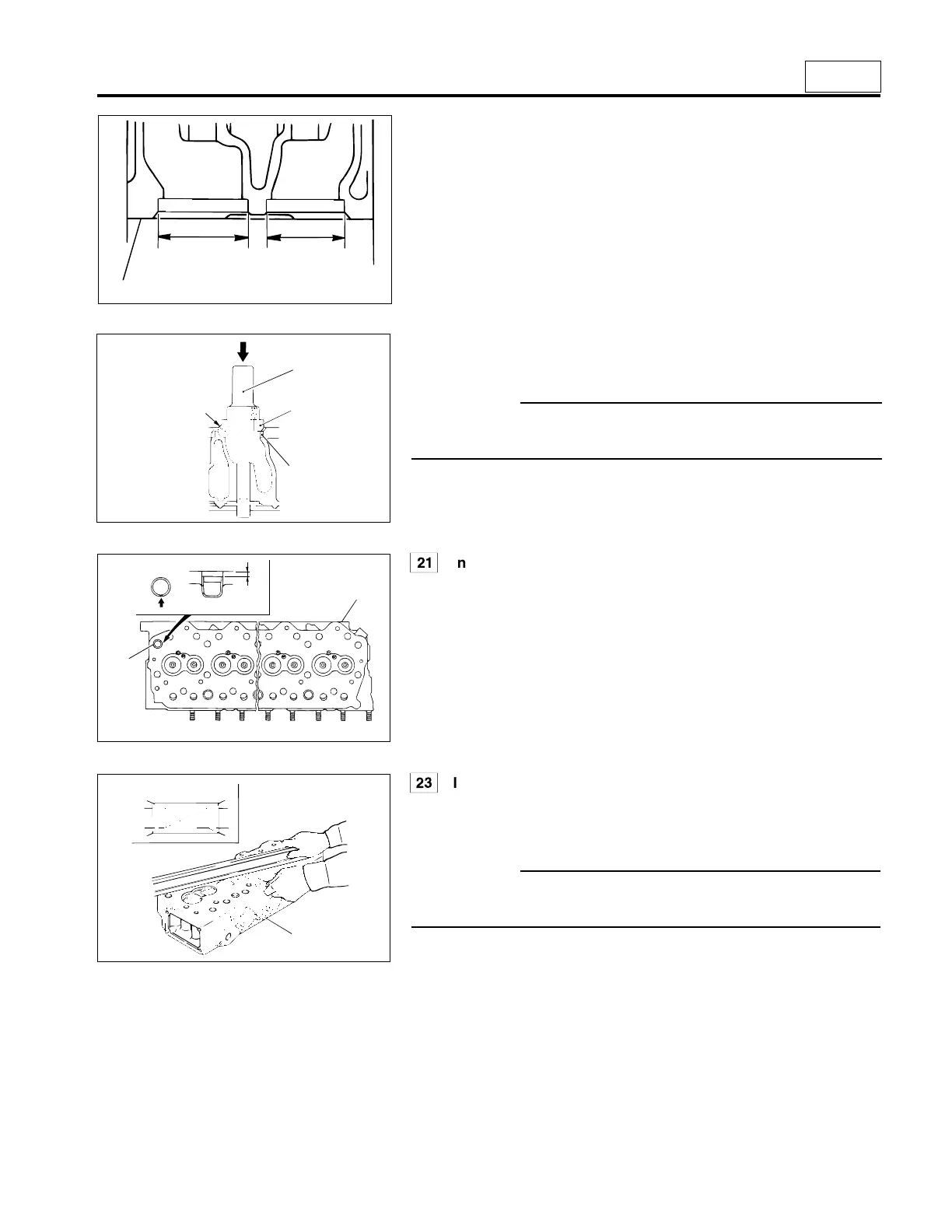

Installation of water director

• With indent A set in the direction as illustrated, press-fit water director

21 into cylinder head 23 to the specified depth.

1

2

19, 20

G

23

23

E

F

{1.81

+0.00098

in.}

0

{1.54

+0.00098

in.}

0

ø39

+0.025

mm

0

ø46

+0.025

mm

0

4mm

{0.16 in.}

A

21

23

Loading...

Loading...