11-21

11

78OP

Valve and valve seat

[Inspection]

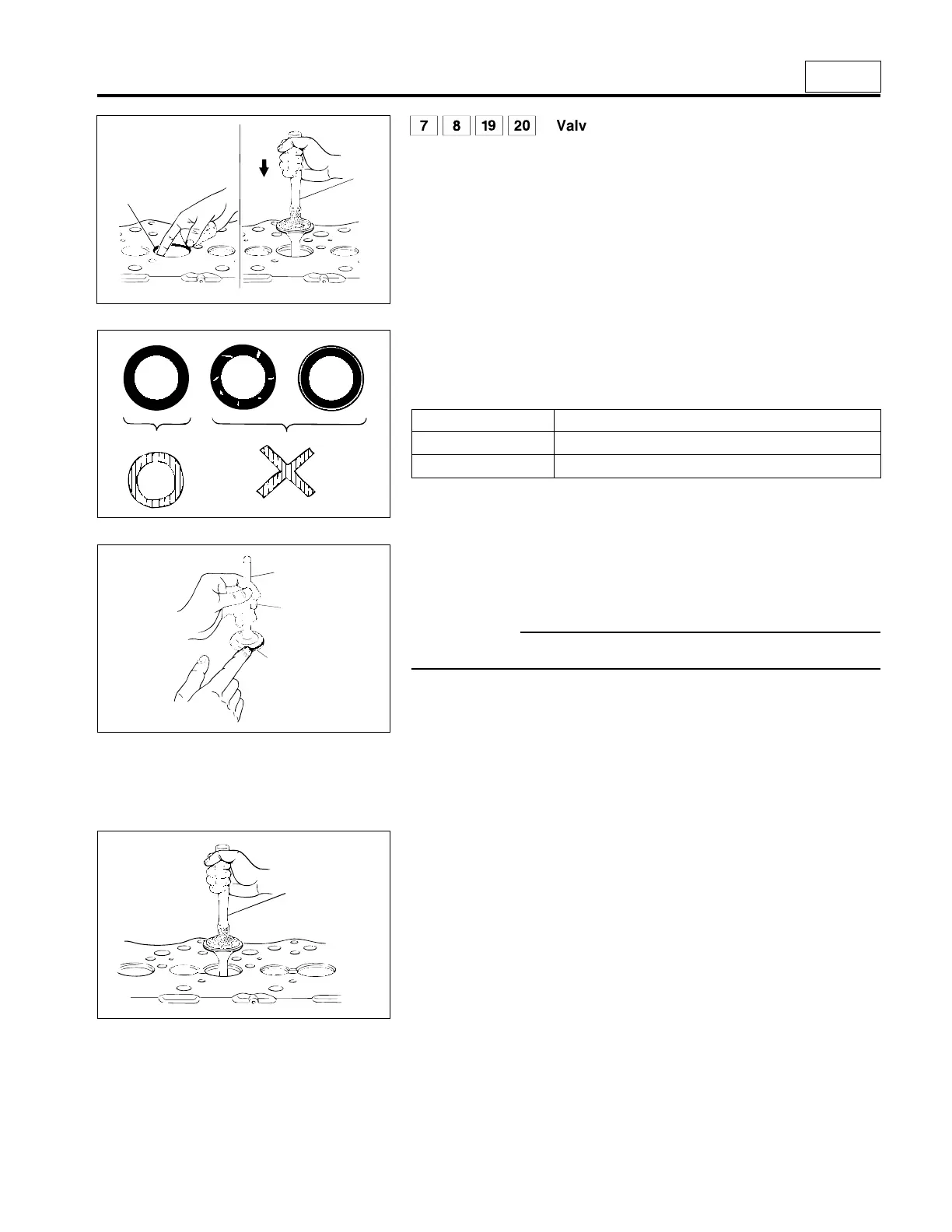

• Apply red lead evenly to entire surface A of valve seats 19, 20 that

contact valves 7, 8.

• Fit valves 7, 8 to valve seats 19, 20 and tap once without rotating.

NOTE

Be sure to carry out inspection under the condition that valves 7,

8 and all parts of valve guides 17, 18 are normal.

01968

A

0

01969

• Check how much red lead has transferred to valves 7, 8 to determine

the contact of the valve and the seat. According to the degree of

abnormality, take proper measures to correct it.

01970

B

A

[Correction]

Valve polishing is done in the following manner:

• Apply valve lapping compound thinly to contact surface A of valves

7,8 with valve seats 19, 20.

CAUTION–

Take care not to smear stems B of valves 7, 8 with the compound.

NOTE

• Start with medium grit compound (120 to 150 grit) and for finish-

ing up, use finer grit (200 grit or finer).

• Mixing with a small amount of engine oil will make the compound

consistent and make even application easier.

7, 8

01971

• Tap valves 7, 8 against valve seats 19, 20 several times while rotating

the valves slightly at each strike.

• Clean off the compound with gas oil.

• Apply engine oil to contact surface A of valve seats 19, 20 and smooth

the surface.

• Check the contact of valves 7, 8 and valve seats 19, 20.

• If contact does not take place completely around the seat, replace

valve seats 19, 20.

0

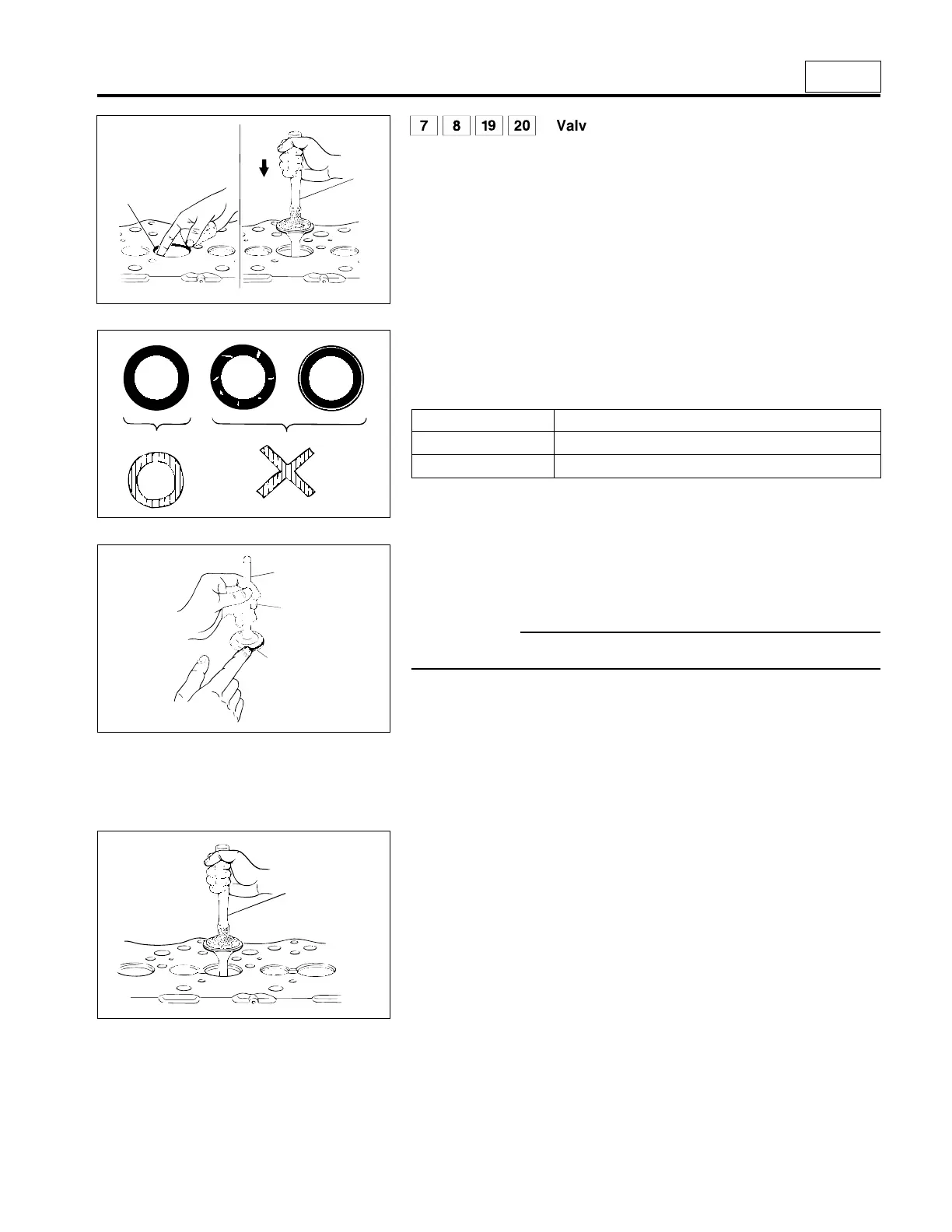

Contact conditions Correction measures

Minor fault Valve lapping

Major fault Repair of valve and seat or replacement of both

Loading...

Loading...