11-31

11

06223

06224

12660

02090

(2) Degree of bend

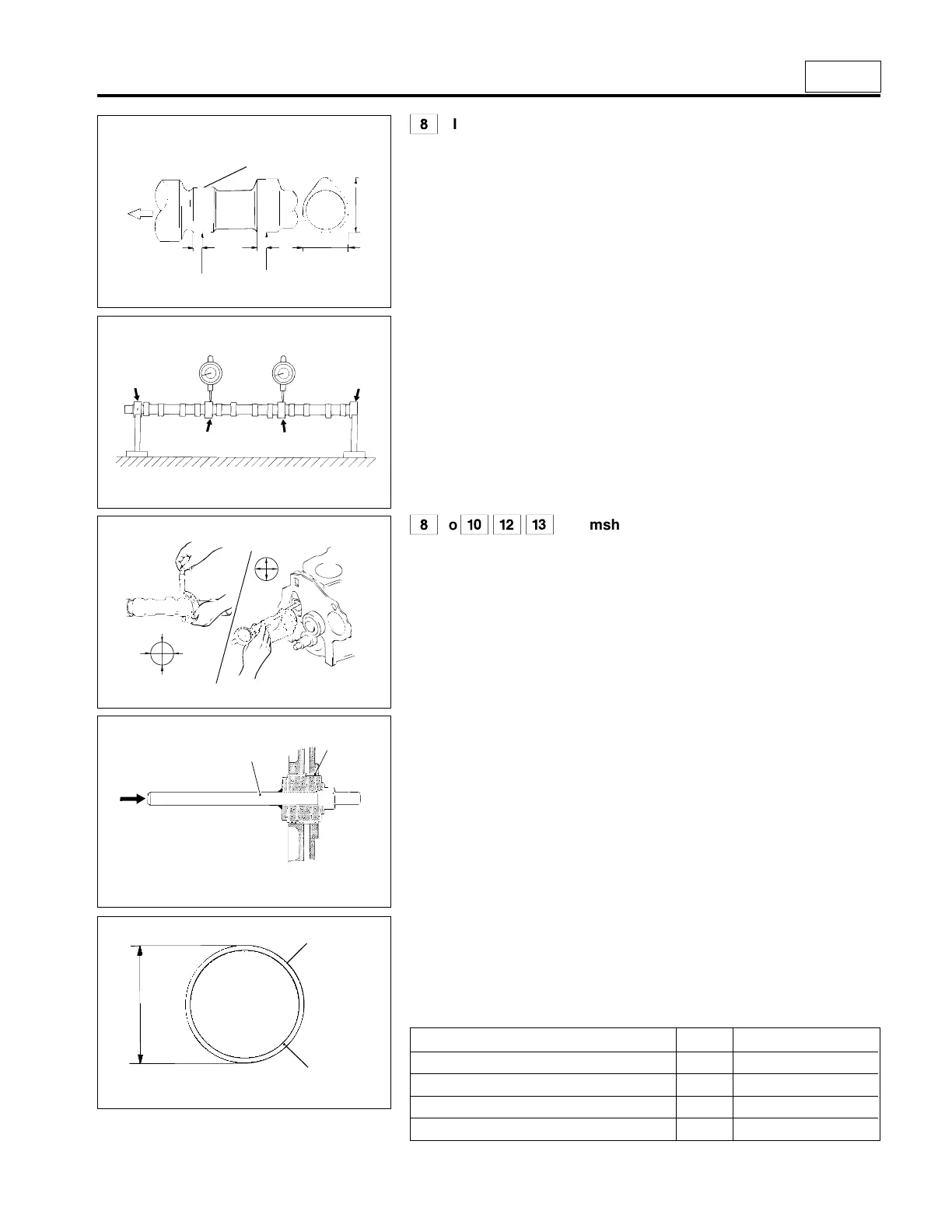

To measure deflection, support camshaft 8 at area E of No.1 journal,

and area F of No.4 journal . Then, measure the amount of deflection at

area G of No.2 journal, and area H of No.3 journal. If any of the

measured values is higher than the limit, replace the camshaft.

NOTE

Degree of bend of camshaft 8 is a half of the indicated value of

the gauge after rotating the shaft 360

°.

8

Inspection of camshaft

(1) Difference between long diameter and short diameter

If the measured value is lower than the limit, replace camshaft 8.

NOTE

Measure at point A, as illustrated, because the cam is tapered.

B : Long diameter

C : Short diameter

D : Front of the engine

8

to

FHI

Camshaft and camshaft bushing

[Inspection]

If the clearance is greater than the limit, replace the faulty parts.

Camshaft bushing

[Removal]

Remove No.3 camshaft bushing 13, and No.4 camshaft bushing 12 from

the rear end of the crankcase.

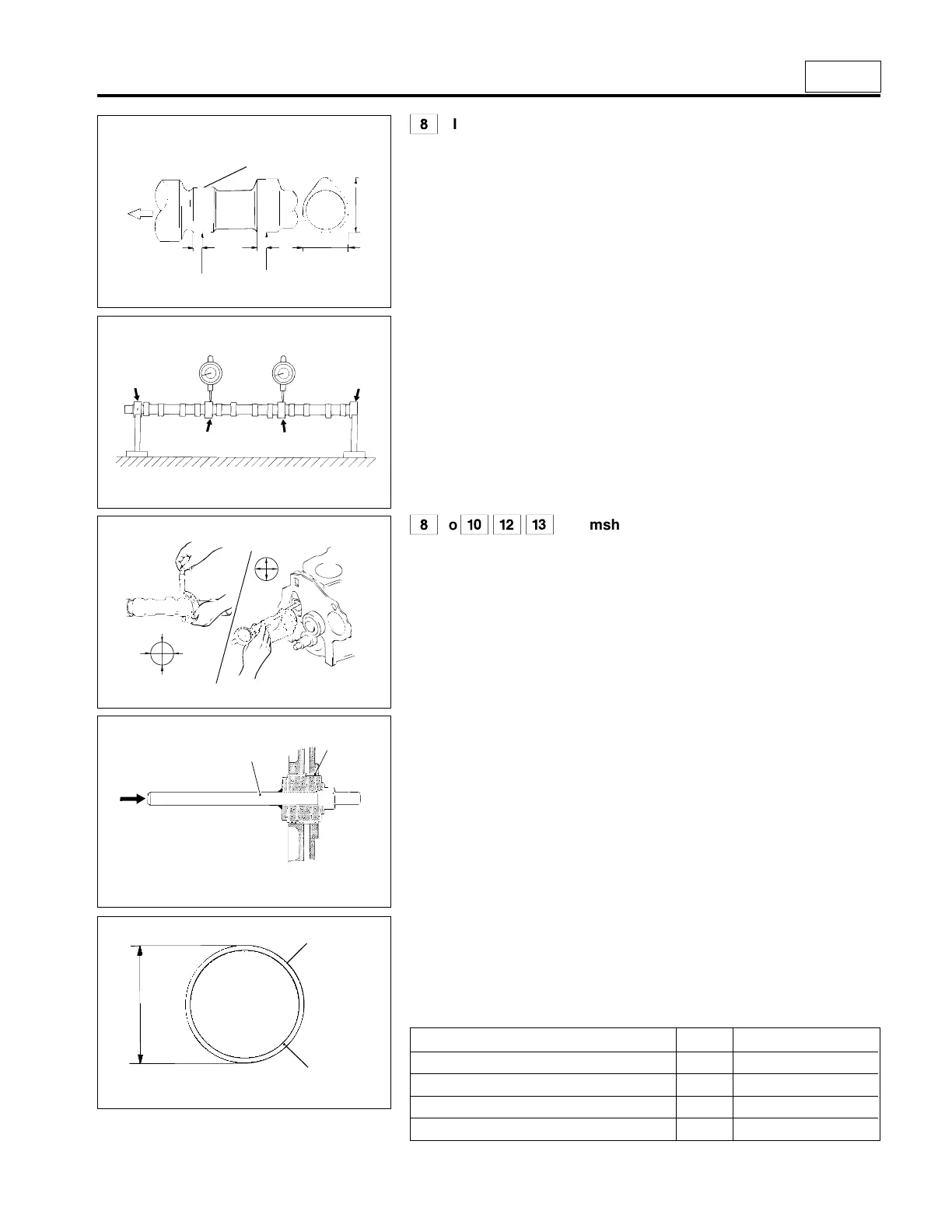

[Press-fitting]

• Identify, by referring to the table below, No.1 to No.4 camshaft bush-

ings by noting marks “1”, “2”, “3”, “4” on camshaft bushings 9, 10,

12, 13. If you cannot identify the mark, measure outer diameter A of

the bushing and refer to the table below.

Bushing No. (from the front of the engine) Mark

Outer diameter A (mm {in.})

No.1 1 ø58.50 {2.30}

No.2 2 ø58.06 {2.28}

No.3 3 ø57.5 {2.26}

No.4 4 ø57.06 {2.25}

03552

A

A

D

B

C

8

7.5 mm

{0.30 in.}

7.5 mm

{0.30 in.}

9, 10, 12, 13

0

H

G

E

F

“1”, “2”, “3”, “4”

9, 10, 12, 13

A

Loading...

Loading...