FRONT

AXLE

& STEERING

LINKAGE

SYSTEM

INSPECTION

Clean the disassembled

parts

by washing.

Inspect gears and pinions

to

be sure

their

teeth

are in good condition. Check

to

be sure

that

each bearing

is

capable

of

smooth

rotation.

Examine each enclosure

part

(housing, case and

the like) for evidence

of

cracking and repair

or

replace cracked parts,

if

any.

REASSEMBLY

Before commencing reassembly, be sure

that

necessary replacements and repair

jobs

have all

been effected and

that

each

part

meets

the

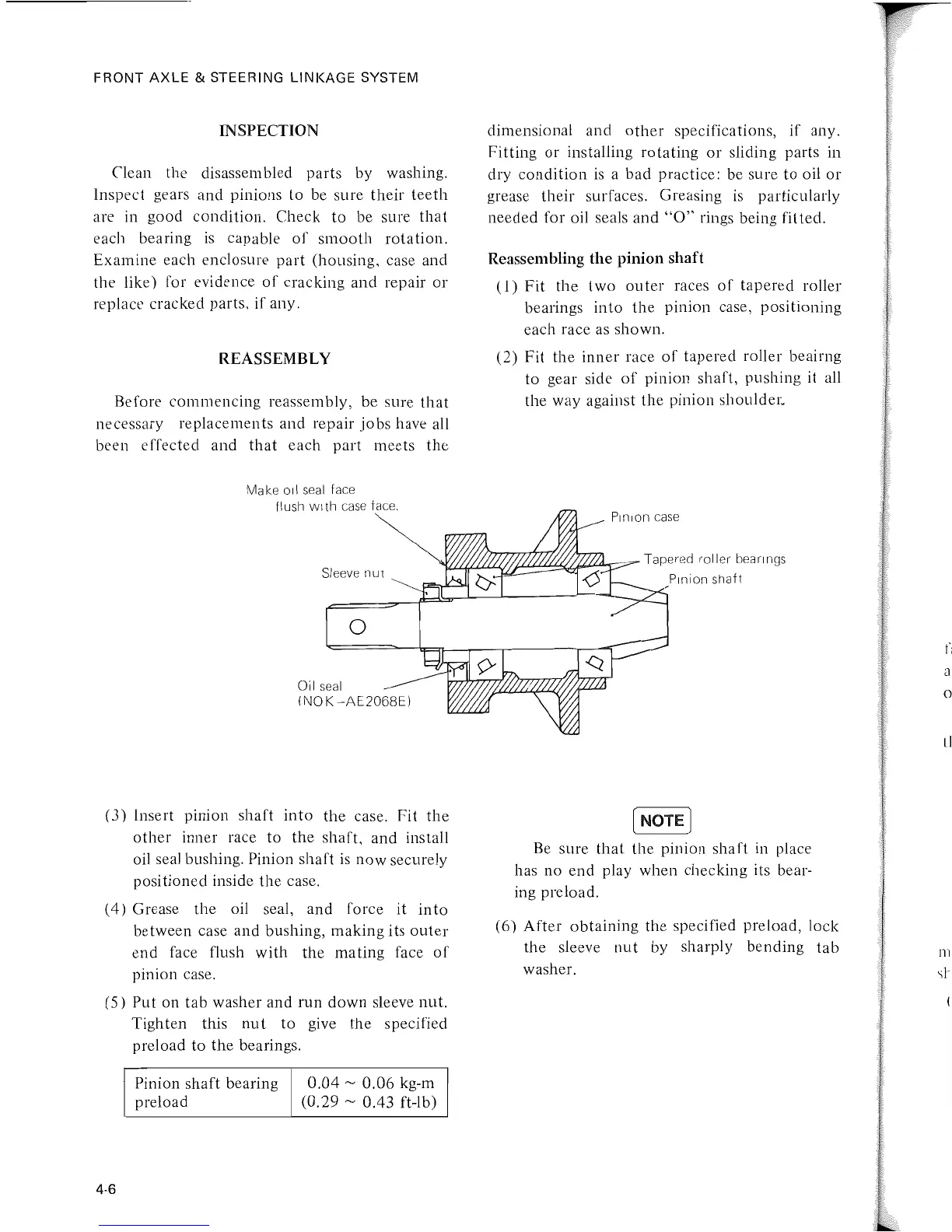

Make oil

seal

face

flush

with

case

face.

dimensional and

other

specifications,

if

any.

Fitting or installing

rotating

or

sliding parts in

dry

condition

is

a bad practice: be sure

to

oil

or

grease

their

surfaces. Greasing is particularly

needed for oil seals and

"0"

rings being fitted.

Reassembling

the pinion

shaft

(I)

Fit

the

two

outer

races

of

tapered

roller

bearings

into

the

pinion case, positioning

each race

as

shown.

(2)

Fit

the

inner

race

of

tapered roller beairng

to

gear side

of

pinion shaft, pushing it all

the way against the pinion shoulder..

Pinion

case

Sleeve

nut

'ftL¥CLLJ.~e~~6f~~~Tapered

roller

bearings

Pinion shaft

o

Oil

seal

(NO

K-AE2068E)

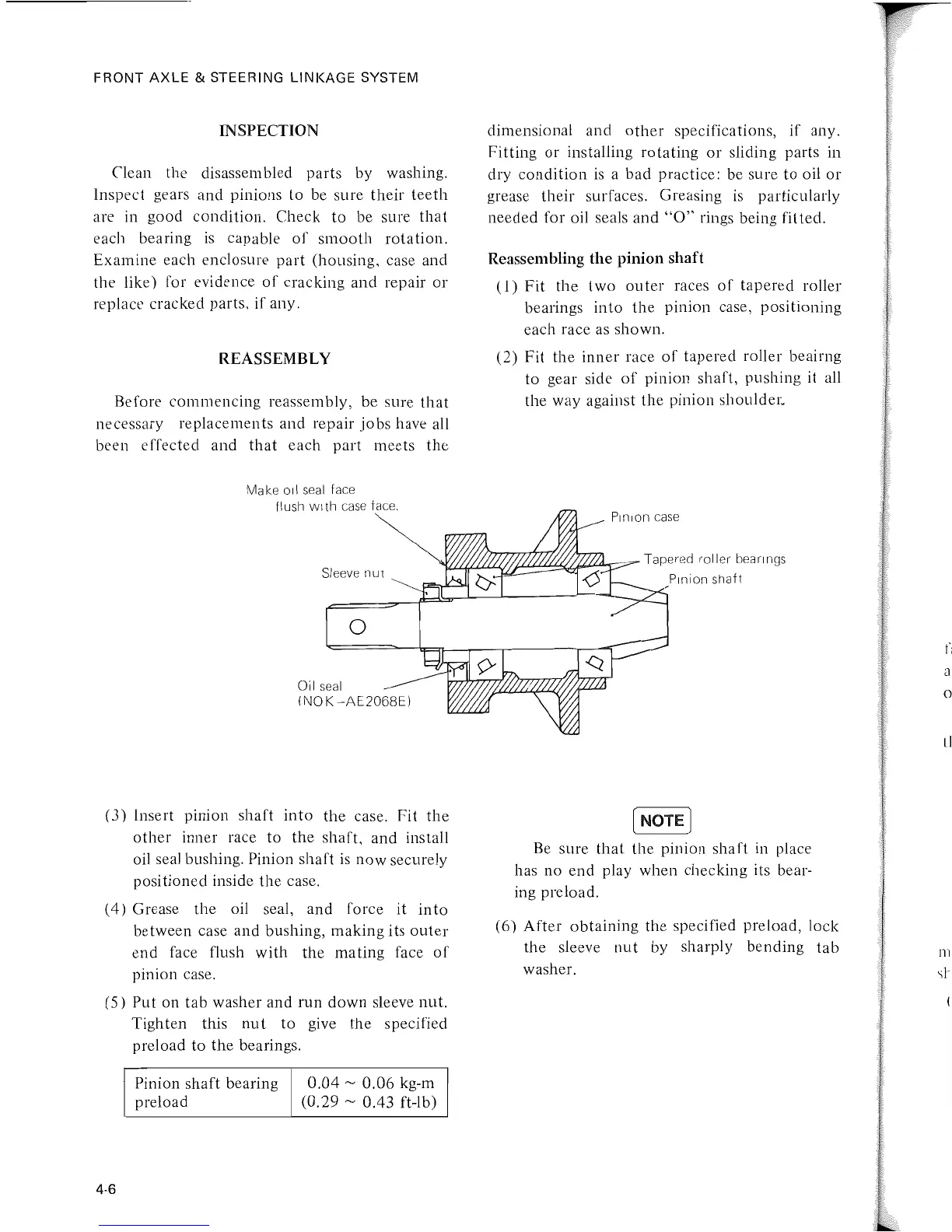

(3) Insert pinion

shaft

into

the

case.

Fit

the

other

inner race

to

the

shaft,

and

install

oil seal bushing. Pinion

shaft

is

now

securely

positioned inside the case.

(4) Grease the oil seal,

and

force it

into

between case and bushing,

making

its

outer

end face flush

with

the

mating face

of

pinion case.

(5)

Put

on

tab

washer and run

down

sleeve nut.

Tighten this

nut

to

give

the

specified

preload

to

the

bearings.

Pinion shaft bearing

preload

0.04

~

0.06 kg-m

(0.29

~

0.43 ft-Ib)

[NOTE]

Be

sure

that

the pinion

shaft

in place

has no end play when checking its bear-

ing preload.

(6)

After

obtaining

the

specified preload, lock

the sleeve

nut

by sharply bending tab

washer.

f:

a

o

tl

Loading...

Loading...