I,

e

e

p

a

.I

e

f

1-

J

f

j

s

e

y

e

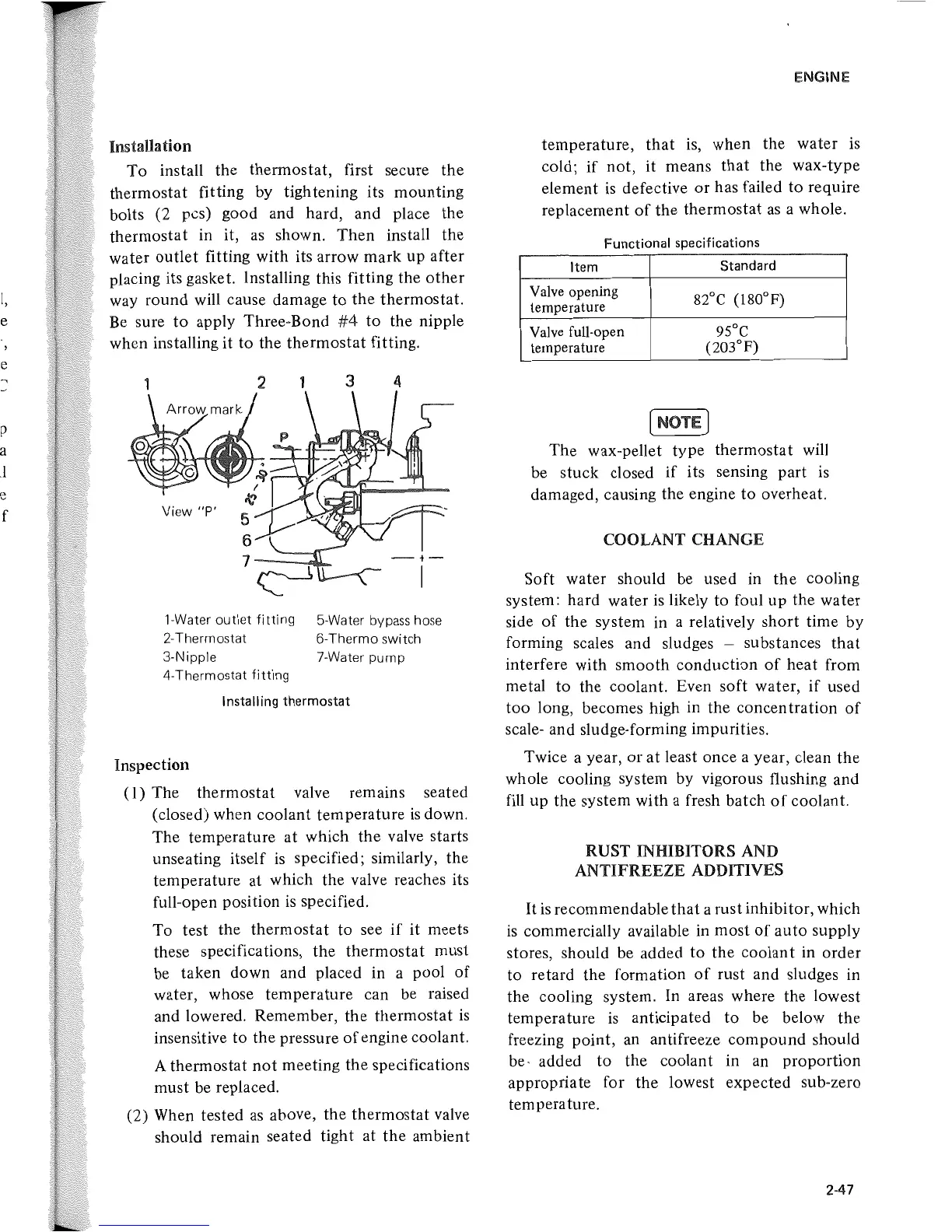

Installation

To

install

the

thermostat,

first secure

the

thermostat

fitting by tightening its

mounting

bolts (2 pes) good and hard, and place

the

thermostat

in it,

as

shown.

Then

install

the

water

outlet

fitting with its arrow

mark

up

after

placing its gasket. Installing this fitting

the

other

way

round

will cause damage

to

the

thermostat.

Be

sure

to

apply Three-Bond

#4

to

the

nipple

when installing it

to

the

thermostat

fitting.

1

2

1-Water

outlet

fitting

2-Thermostat

3-Nipple

4-Thermostat

fitting

3

4

5-Water

bypass

hose

6-Thermo

switch

7-Water

pump

Installing

thermostat

Inspection

(I)

The

thermostat

valve remains seated

(closed) when

coolant

temperature

is

down.

The

temperature

at which

the

valve starts

unseating itself

is

specified; similarly, the

temperature at which

the

valve reaches its

full-open position

is

specified.

To

test the

thermostat

to see

if

it meets

these specifications,

the

thermostat

must

be

taken

down and placed in a pool

of

water, whose

temperature

can be raised

and lowered. Remember,

the

thermostat

is

insensitive

to

the

pressure

of

engine coolant.

A

thermostat

not

meeting

the

specifications

must

be replaced.

(2) When tested

as

above,

the

thermostat

valve

should remain seated tight at

the

ambient

ENGINE

temperature,

that

is, when

the

water

is

cold;

if

not,

it

means

that

the

wax-type

element is defective

or

has failed

to

require

replacement

of

the

thermostat

as

a whole.

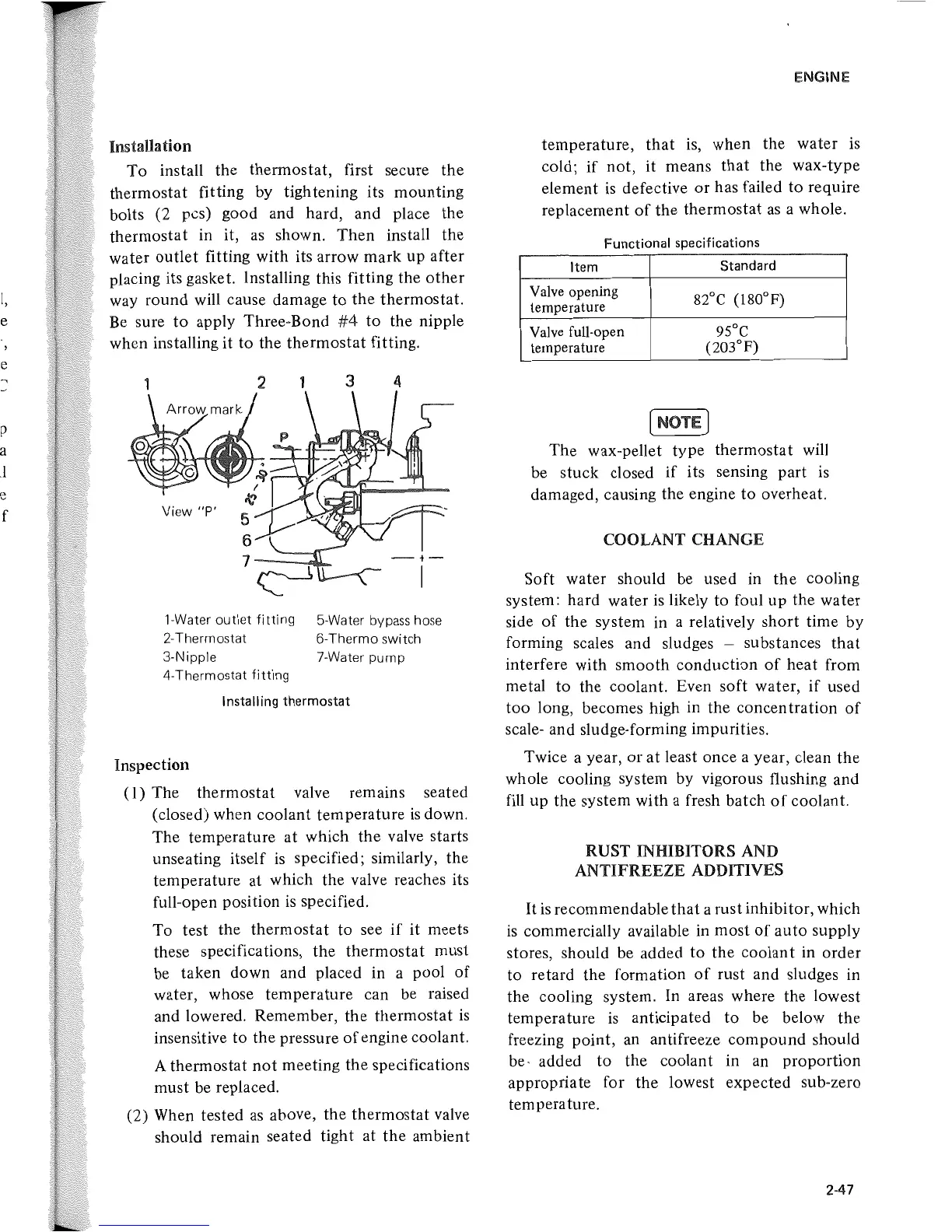

Functional specifications

Item

Standard

Valve opening

82°C (180°F)

temperature

Valve full-open

95°C

temperature

(203°F)

[NOTE]

The

wax-pellet

type

thermostat

will

be

stuck

closed

if

its sensing

part

is

damaged, causing the engine

to

overheat.

COOLANT CHANGE

Soft

water

should be used in

the

cooling

system: hard water is likely

to

foul

up

the

water

side

of

the

system in a relatively

short

time

by

forming scales and sludges - substances

that

interfere with

smooth

conduction

of

heat

from

metal

to

the coolant. Even soft water,

if

used

too

long, becomes high in the

concentration

of

scale- and sludge-forming impurities.

Twice a year,

or

at

least once a year, clean

the

whole cooling system

by

vigorous flushing and

fill

up

the

system with a fresh

batch

of

coolant.

RUST INHIBITORS AND

ANTIFREEZE ADDITIVES

It

is

recommendable

that

a rust inhibitor, which

is

commercially available in

most

of

auto

supply

stores, should be added

to

the

coolant

in

order

to

retard the formation

of

rust and sludges in

the cooling system.

In

areas where

the

lowest

temperature

is

anticipated

to

be below

the

freezing

point,

an antifreeze

compound

should

be added

to

the coolant in an

proportion

appropriate for

the

lowest

expected

sub-zero

temperature.

2·47

Loading...

Loading...