ENGINE

Camshaft and timing gears

The camshaft

is

a high-carbon steel forging

having three journals by which

it

is

fitted

into

and held by

the

cylinder block. Its journal and

cam faces are induction-hardened for increased

resistance

to

wear. Lube oil

is

pressure-fed from

cylinder block

to

each camshaft journal. By a

recess or

notch

provided in the rear journal, lube

oil

is

intermittently supplied through

the

cylinder

head in order

to

lubricate the rocker arms and

related parts

of

the valve mechanism. An oil

hole which permits an excess

of

the oil

to

return

to

the oil pan

is

drilled in the rear

end

of

the

shaft.

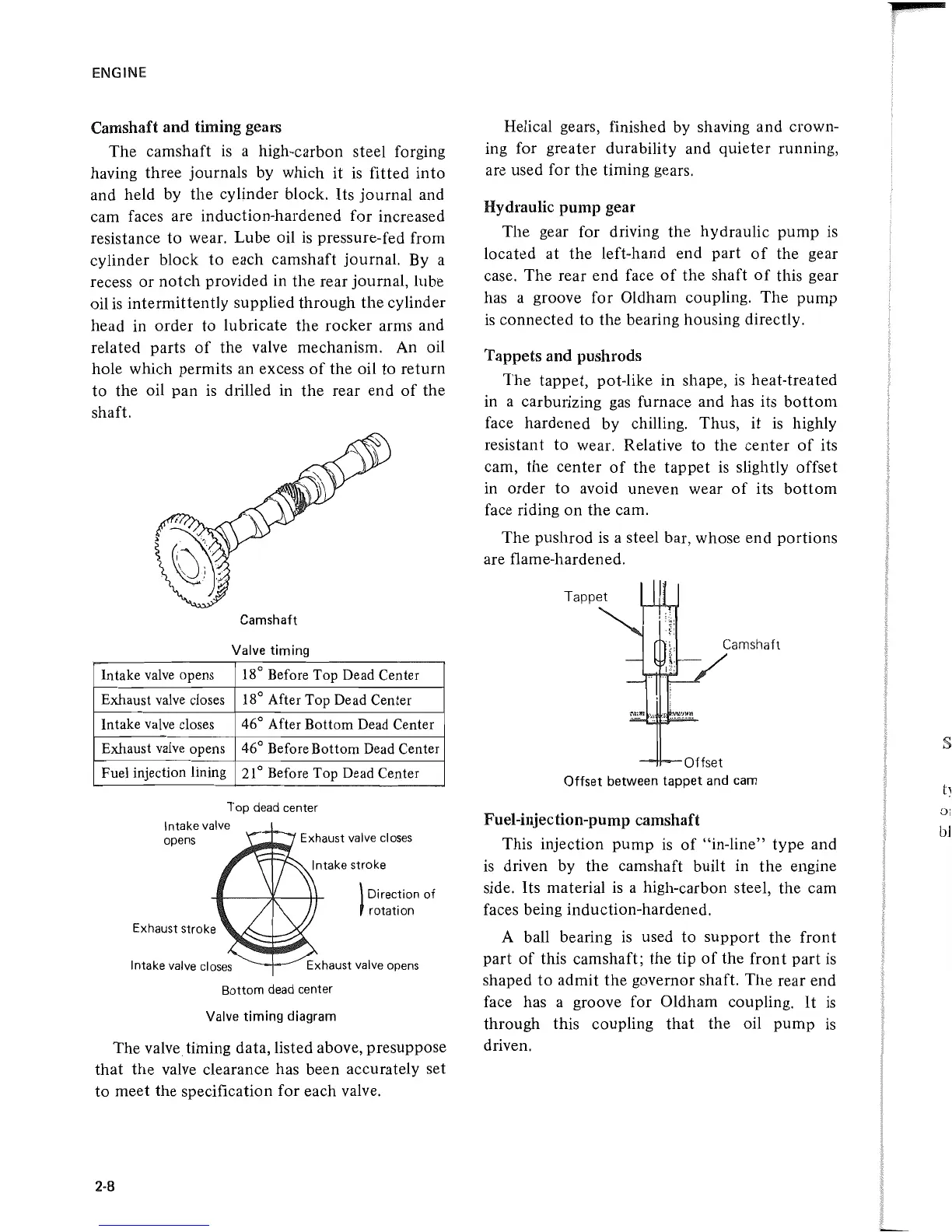

Camshaft

Valve timing

Intake

valve

opens 18° Before Top Dead Center

Exhaust

valve

closes 18° After Top Dead Center

Intake

valve

closes

46° After

Bottom

Dead Center

Exhaust

valve

opens

46° Before

Bottom

Dead Center

Fuel injection lining

21

0

Before Top Dead Center

Top

dead

center

Intake valve

opens

Exhaust valve closes

Exhaust

stroke

Bottom

dead

center

Valve timing diagram

\

Direc~ion

of

f

rotation

The valvetirning data, listed above, presuppose

that

the

valve clearance has been accurately set

to

meet the specification for each valve.

2·8

Helical gears, finished by shaving and crown-

ing for greater durability and quieter running,

are used for the timing gears.

Hydraulic

pump gear

The gear for driving

the

hydraulic

pump

is

located at the left-hand end part

of

the gear

case. The rear end face

of

the shaft

of

this gear

has a groove for Oldham coupling. The pump

is

connected to

the

bearing housing directly.

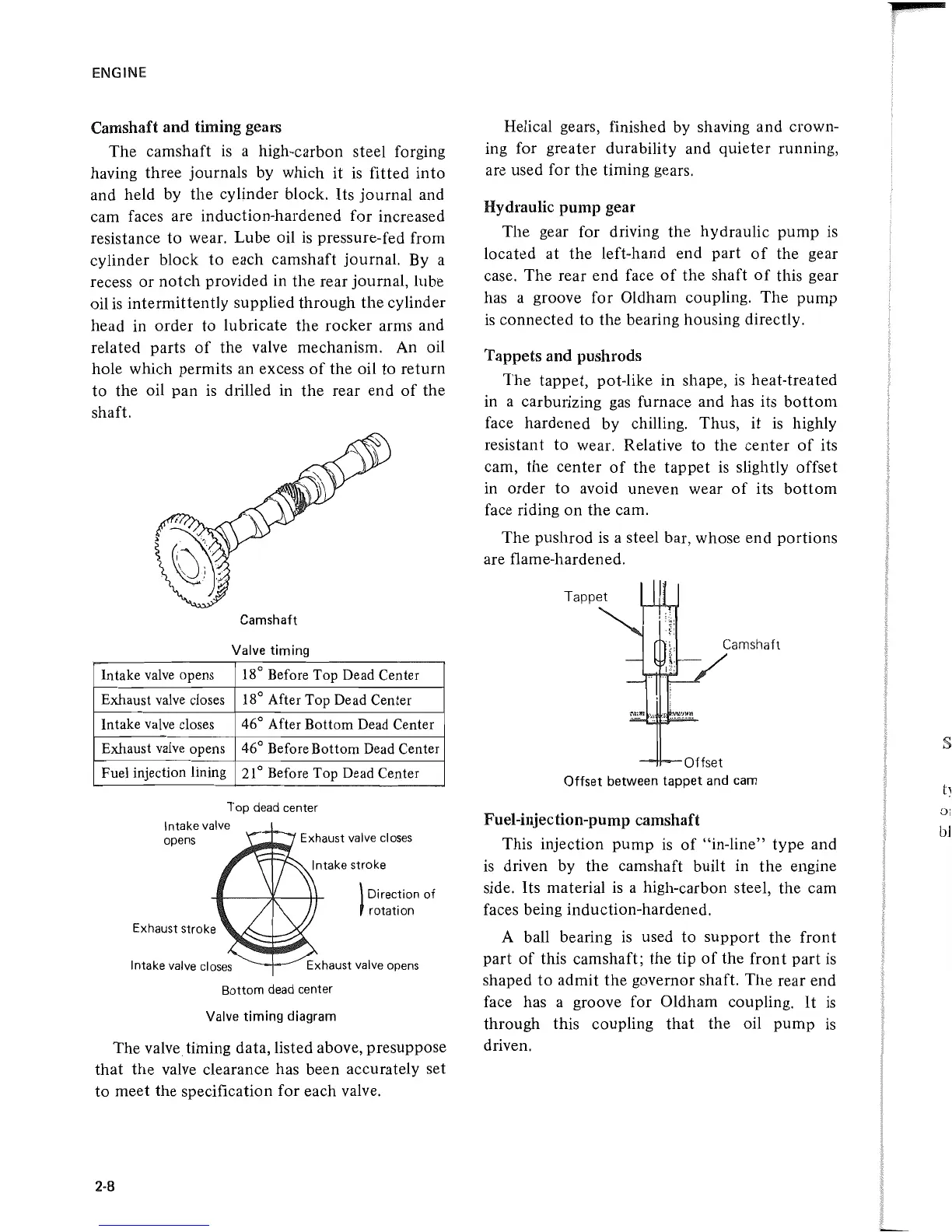

Tappets and pushrods

The tappet, pot-like in shape,

is

heat-treated

in a carburizing

gas

furnace and has its

bottom

face hardened by chilling. Thus, it

is

highly

resistant

to

wear. Relative to

the

center

of

its

cam,

the

center

of

the

tappet

is

slightly offset

in order

to

avoid uneven wear

of

its

bottom

face riding on

the

cam.

The pushrod

is

a steel bar, whose end portions

are flame-hardened.

Offset between tappet and cam

Fuel-injection-pump camshaft

This injection

pump

is

of

"in-line" type and

is

driven by

the

camshaft built in

the

engine

side. Its material

is

a high-carbon steel, the cam

faces being induction-hardened.

A ball bearing

is

used

to

support

the front

part

of

this camshaft; the tip

of

the

front part

is

shaped

to

admit the governor shaft. The rear end

face has a groove for Oldham coupling.

It

is

through this coupling

that

the oil

pump

is

driven.

f

(

c

t

s

0]

bl

Loading...

Loading...