..

Injection-quantity equalizing

adjustment

The three pumping elements are required

to

deliver the same

quantity

of

fuel for each

control rack position. The

requirement

is

satis-

fied by allowing the

two

plunger barrels to be

angularly repositioned while the third barrel

is

kept

fixed in place. There are two adjusting

plates, each functioning

as

a cam

to

angularly

reposition the barrel.

o

rr:;;J3)

..

W

0-.-

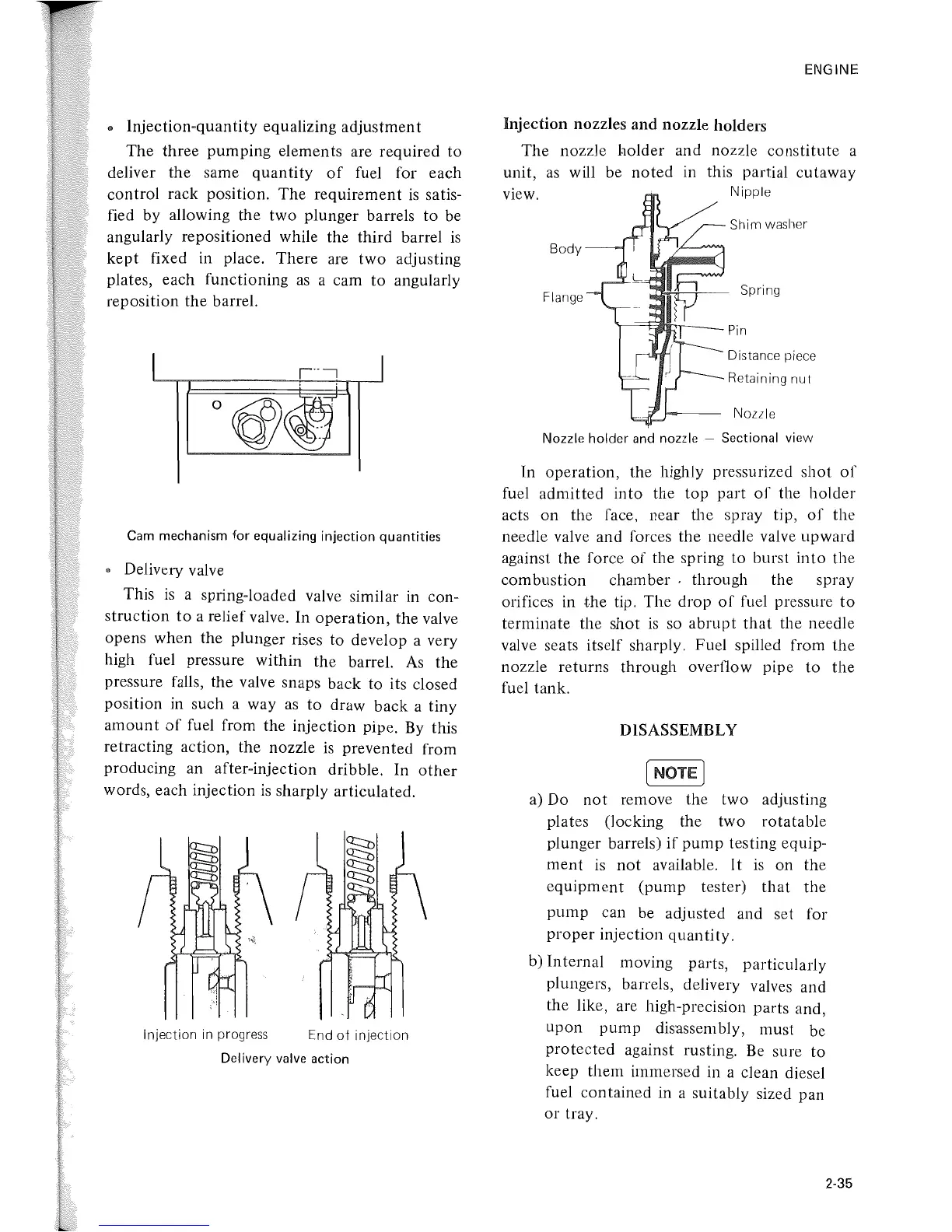

Cam

mechanism for equalizing injection quantities

Delivery valve

This

is

a spring-loaded valve similar

in

con-

struction

to

a relief valve. In operation, the valve

opens when the plunger rises

to

develop a very

high fuel pressure within the barrel.

As

the

pressure falls, the valve snaps back to its closed

position in such a way as to draw back a tiny

amount

of

fuel from the injection pipe. By this

retracting action, the nozzle is prevented from

producing an after-injection dribble. In

other

words, each injection

is

sharply articulated.

Injection in progress

End

of

injection

Del

ivery valve action

ENGINE

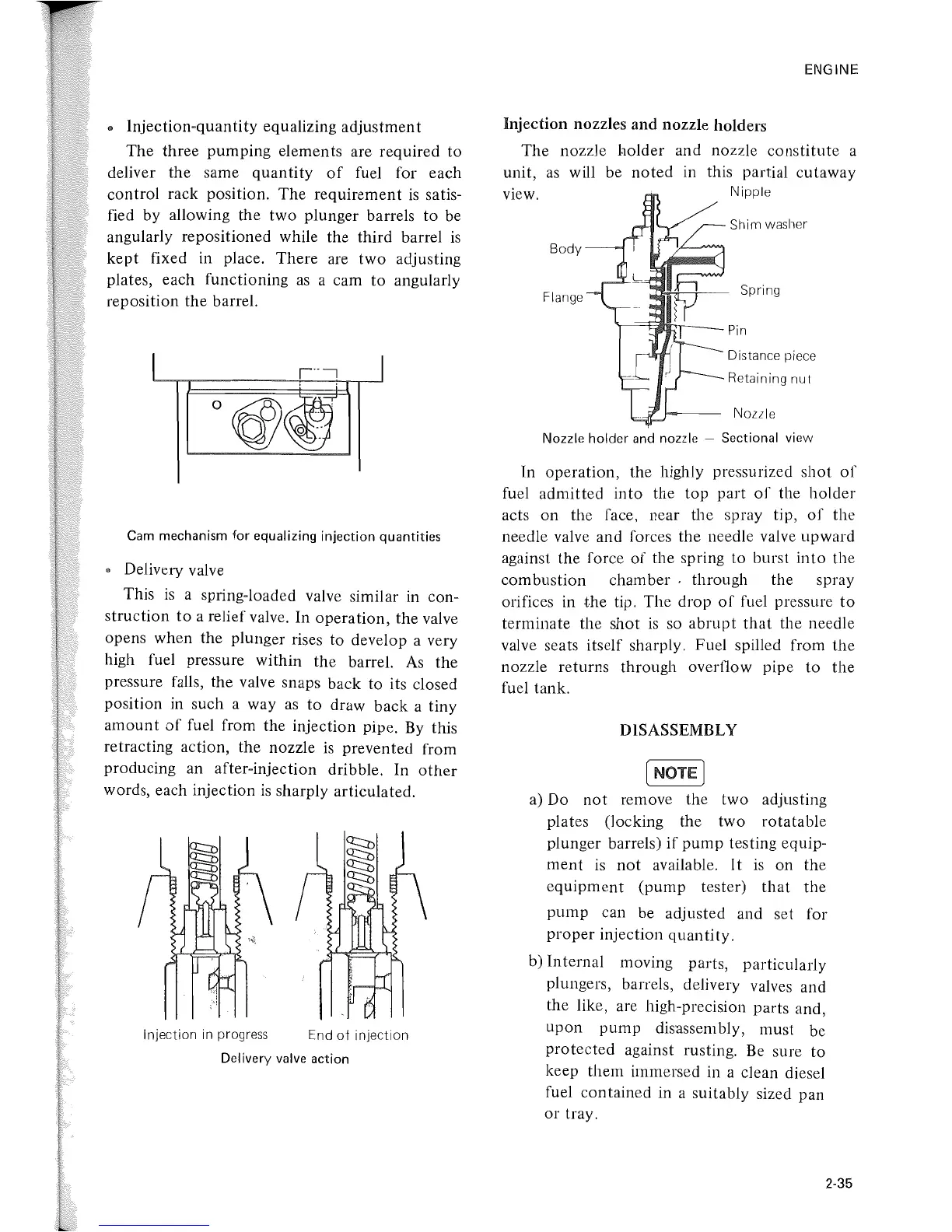

Injection nozzles

and

nozzle holders

The nozzle

l:l.Older

and nozzle

constitute

a

unit,

as

will be

noted

in this partial cutaway

view.

Body

Flange

Nipple

Shim

washer

Spring

Pin

Distance piece

Retaining

nut

Nozzle

Nozzle holder and nozzle - Sectional view

In operation, the highly pressurized

shot

of

fuel

admitted

into the top

part

of

the

holder

acts on the face, near the spray tip,

of

the

needle valve and forces the needle valve upward

against

the

force

of

the spring

to

burst

into

the

combustion

chamber.

through the spray

orifices in

the

tip. The drop

of

fuel pressure

to

terminate the

shot

is

so

abrupt

that

the needle

valve seats itself sharply. Fuel spilled from the

nozzle returns through overf1ow pipe

to

the

fuel tank.

DISASSEMBLY

[NOTE]

a) Do

not

remove the two adjusting

plates (locking the two rotatable

plunger barrels)

if

pump

testing equip-

ment

is

not

available.

It

is

on

the

equipment

(pump tester)

that

the

pump

can be adjusted and set for

proper

injection

quantity.

b) Internal moving parts, particularly

plungers, barrels, delivery valves and

the like, are high-precision parts and,

upon

pump

disassembly, must be

protected

against rusting.

Be

sure

to

keep

them

immersed in a clean diesel

fuel contained in a suitably sized pan

or tray.

2-35

Loading...

Loading...