gs,

ast

his

he

.sis

he

).4

le

(2) Push ball bearing (H)

onto

rear-side shaft,

bringing

the

bearing all the way

until

it

meets the circlip (G)

on

the

rear end.

Installing

the

shaft

(F)

in transmission case,

mount

collar

(I)

and gear

23T

(P), with its

claws coming

on

the rear side.

(3)

Fit

the collar

(0)

to

the

shaft,

(F)

making

sure

the

splined fit is

smooth.

<Front-side

shaft>

(l)

Grease

"0"

ring and fit

it

to

PTO shifter.

Install the shifter by bringing

it

in to trans-

mission case.

(2) Install circlip (L)

on

the

rear

portion

of

front-side shaft, (J)

and

mount

the

inner

race

of

ball bearing

..

(M)

(3) Set circlip (D

on

that

part

of

front-side

shaft

where gear

30T

takes its position.

Mount

thrust liner

(E)and

gear

30T

(be sure

to

loc(!te its clutching claws on the

correct

side), fit

thrust

liner,

(E)

and retain

them

by

installing circlip. (K)

(4)

Put

on gear 20T-26T,

locating

the

claws on

the

correct side, and feed

the

front-side

shaft

into

transmission case.

(5) Set the shifter on gear 20T-26T, and posi-

tion the shaft

(1)

and

shifter

in place,

and install ball bearing

(B)

on

front

side.

TRANSMISSION SYSTEM

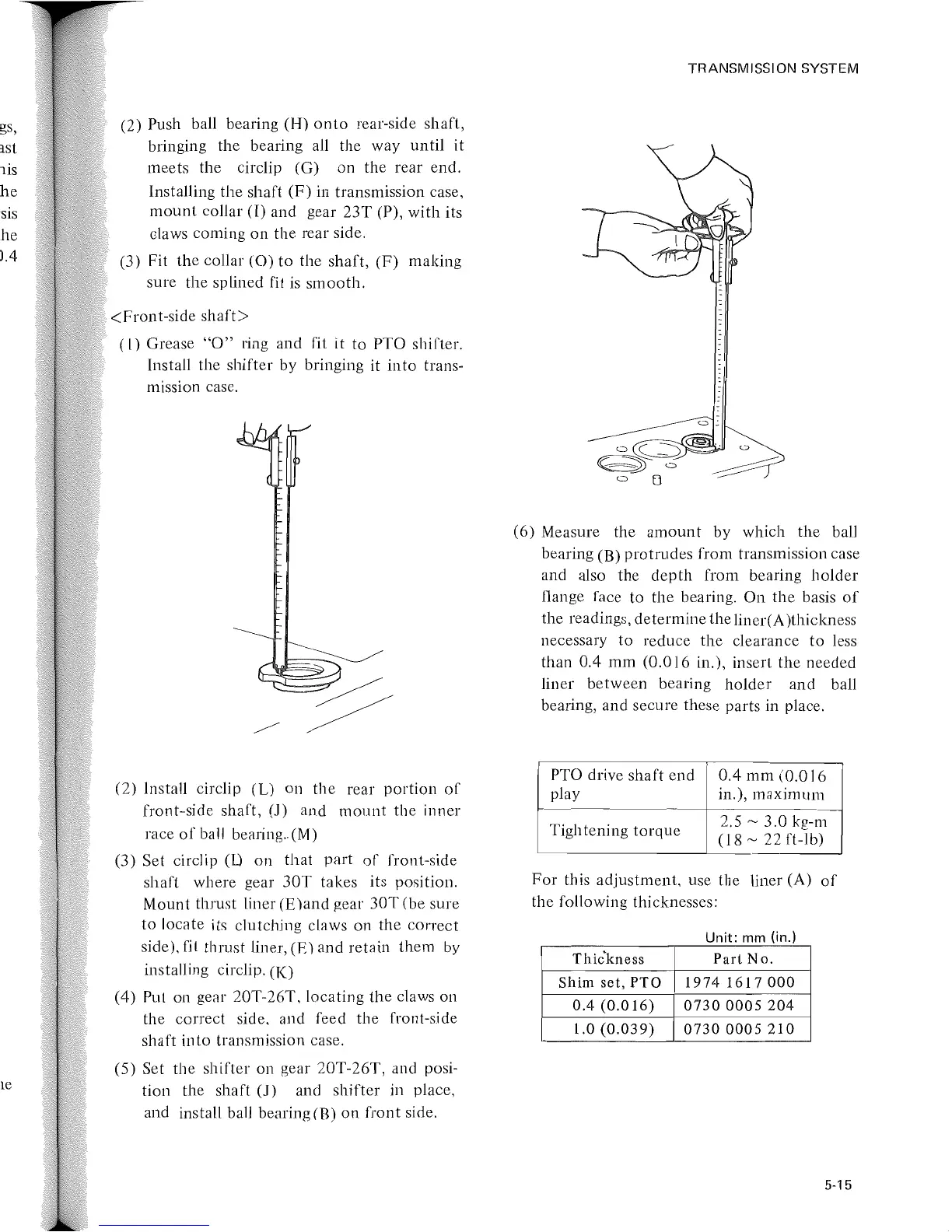

(6) Measure the

amount

by which

the

ball

bearing (B)

protrudes

from transmission case

and also

the

depth

from bearing

holder

flange face

to

the bearing.

On

the

basis

of

the readings, determine theliner(A)thickness

necessary

to

reduce

the

clearance

to

less

than

0.4

mm

(0.016

in.), insert the

needed

liner

between

bearing

holder

and

ball

bearing, and secure these parts in place.

PTO drive

shaft

end

0.4

mm

(0.016

play

in.), m(!ximum

Tightening

torque

2.5

~

3.0

kg-m

(18

~

22 ft-lb)

For

this

adjustment,

use the liner (A)

of

the following thicknesses:

Unit·

mm

(in)

Thic'kness

Part

No.

Shim

set,

PTO

1974

1617000

0.4

(0.016)

0730

0005

204

1.0

(0.039)

07300005210

5-15

Loading...

Loading...