TRANSMISSION SYSTEM

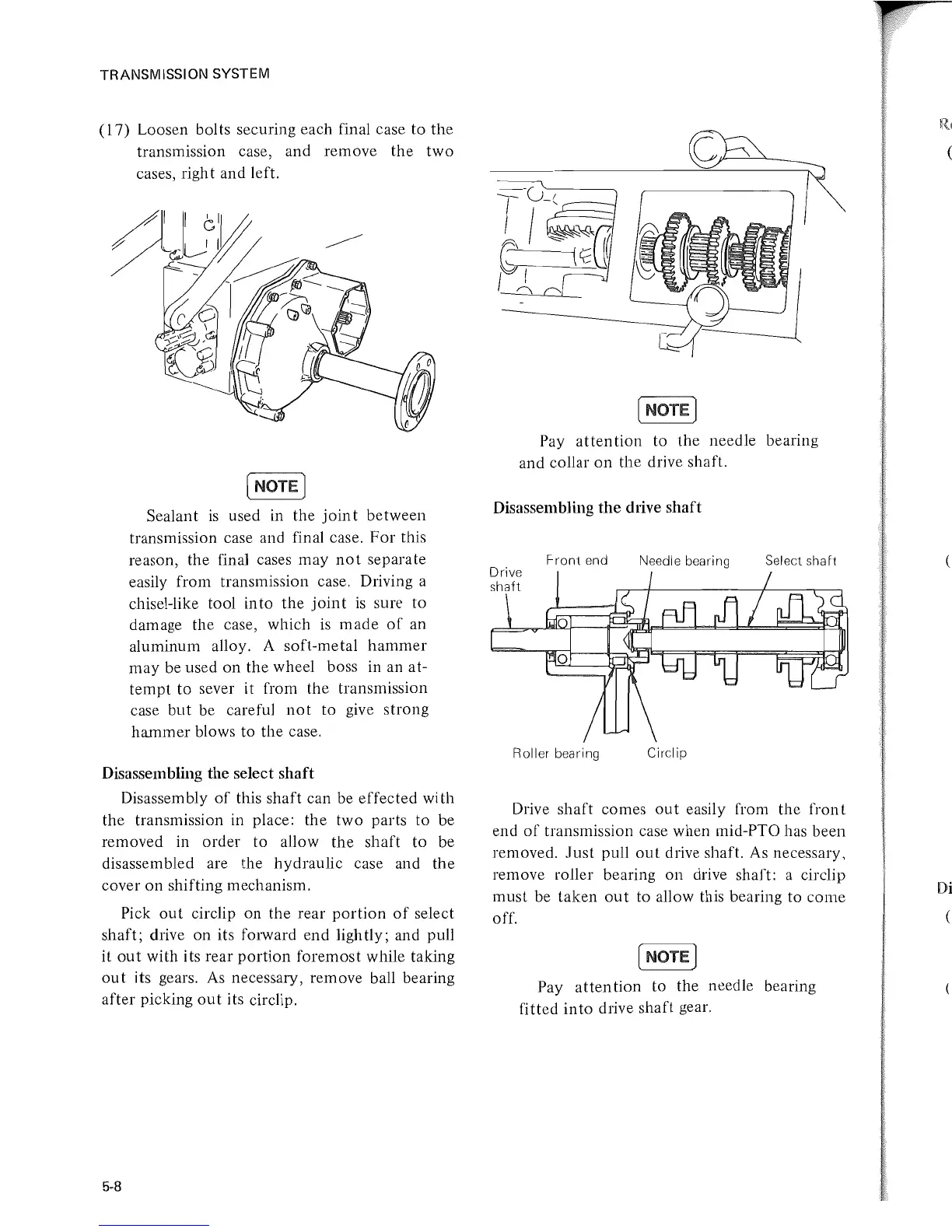

(17) Loosen bolts securing each final case

to

the

transmission case, and remove

the

two

cases, righ t and left.

[NOTE]

Sealan t

is

used in the join t between

transmission case and final case.

For

this

reason, the final cases may

not

separate

easily from transmission case. Driving a

chisel-like tool

into

the

joint

is

sure to

damage the case, which

is

made

of

an

aluminum alloy. A soft-metal

hammer

may be used on the wheel boss

in

an a

t-

tempt

to

sever

it

from the transmission

case

but

be careful

not

to give strong

hammer

blows

to

the case.

Disassembling the select

shaft

Disassembly

of

this shaft can be effected with

the transmission in place: the two parts to be

removed in order to allow

the

shaft to be

disassembled are the hydraulic case and the

cover

on

shifting mechanism.

Pick

out

circlip on the rear

portion

of

select

shaft; drive on its forward end lightly; and pull

it

out

with its rear

portion

foremost while taking

ou t its gears.

As

necessary, remove ball bearing

after picking

out

its circlip.

5-8

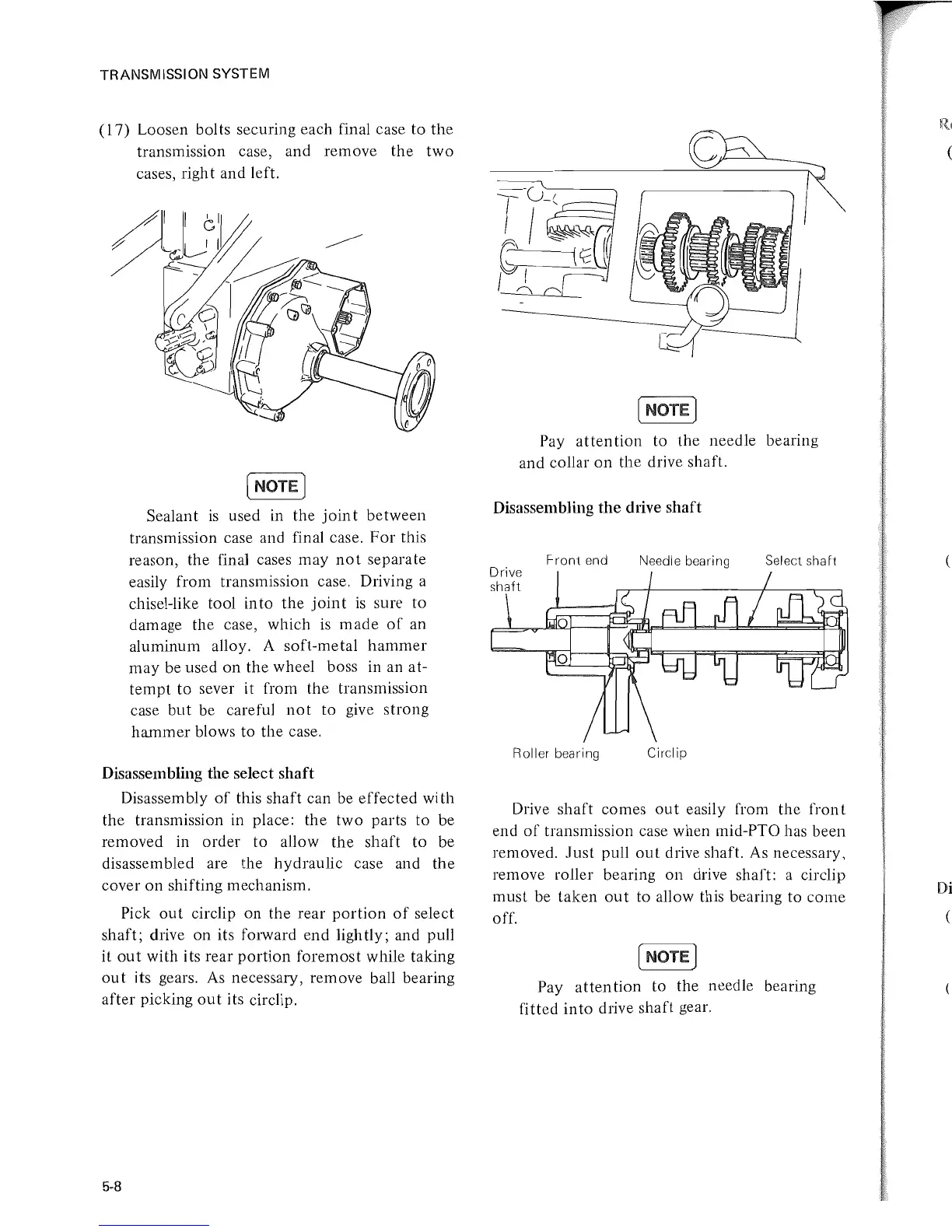

[NOTE]

Pay

attention

to

the needle bearing

and collar

on

the

drive shaft.

DisassembJing

the

drive shaft

Front

end

Needle bearing

Select shaft

Roller bearing

Circlip

Drive shaft comes

out

easily from the

front

end

of

transmission case when mid-PTO has been

removed.

Just

pull

out

drive shaft.

As

necessary,

remove roller bearing on drive shaft: a circlip

must be taken

out

to allow this bearing to come

off.

[NOTE]

Pay

attention

to the needle bearing

fitted

into

drive shaft gear.

Loading...

Loading...