Troubleshooting

6-5

Part 1024496_06

2014 Nordson Corporation

Returning the Melter Setup to Factory Settings

By returning the melter to its factory setting many common melter problems

can be isolated to either a problem with the melter settings or the melter

hardware.

To return the melter to its factory settings, simultaneously press and hold the

Setup key and the right‐display DOWN arrow key, and then, while holding

down these keys, cycle the melter control switch off and on. When the melter

restarts, release the two keys.

Identifying Electrical Components

Tables 6‐2 through 6‐5 describe the circuit board indicators, connection

points, and test points that are referred to in the troubleshooting flowchart.

Figure 6‐1 illustrates the location of each of these circuit board components.

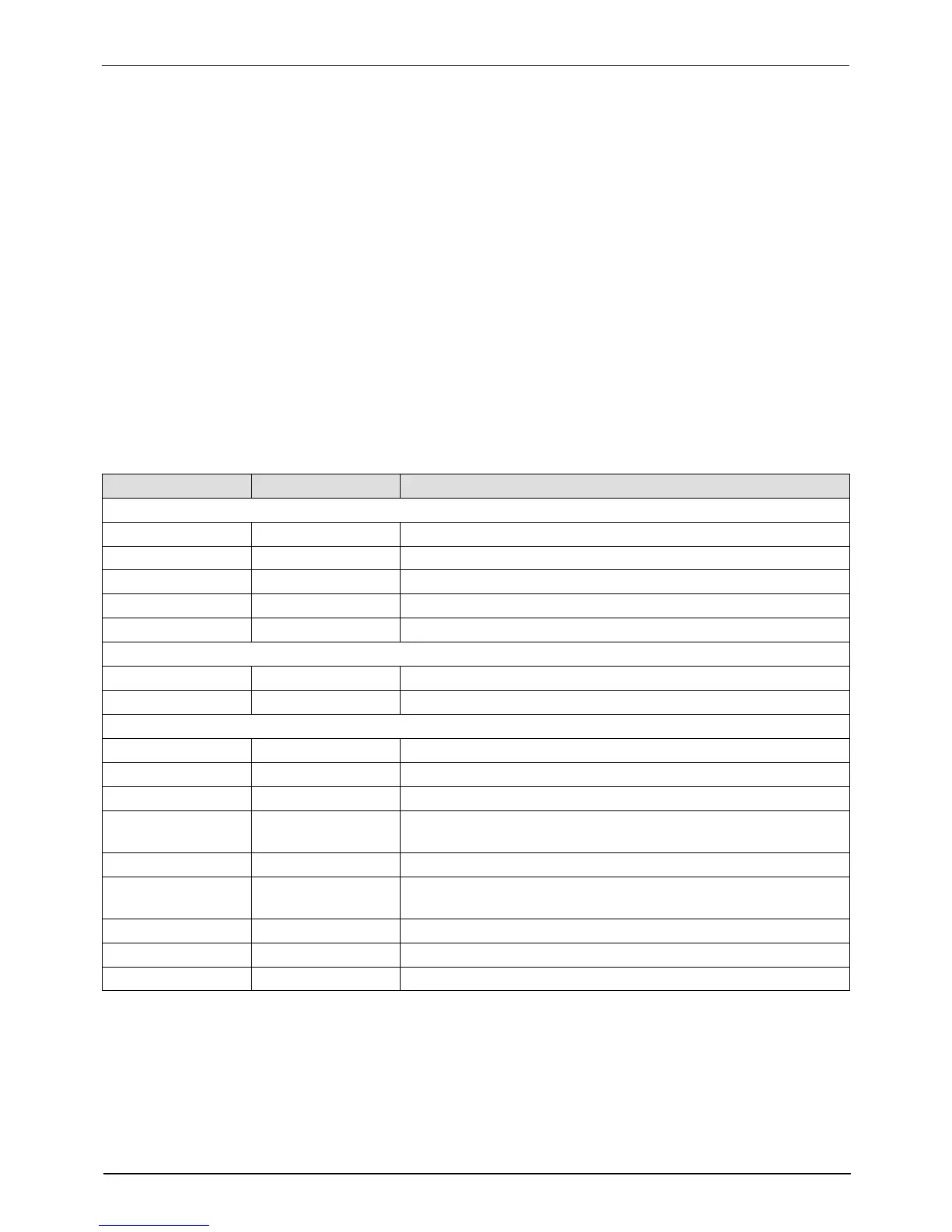

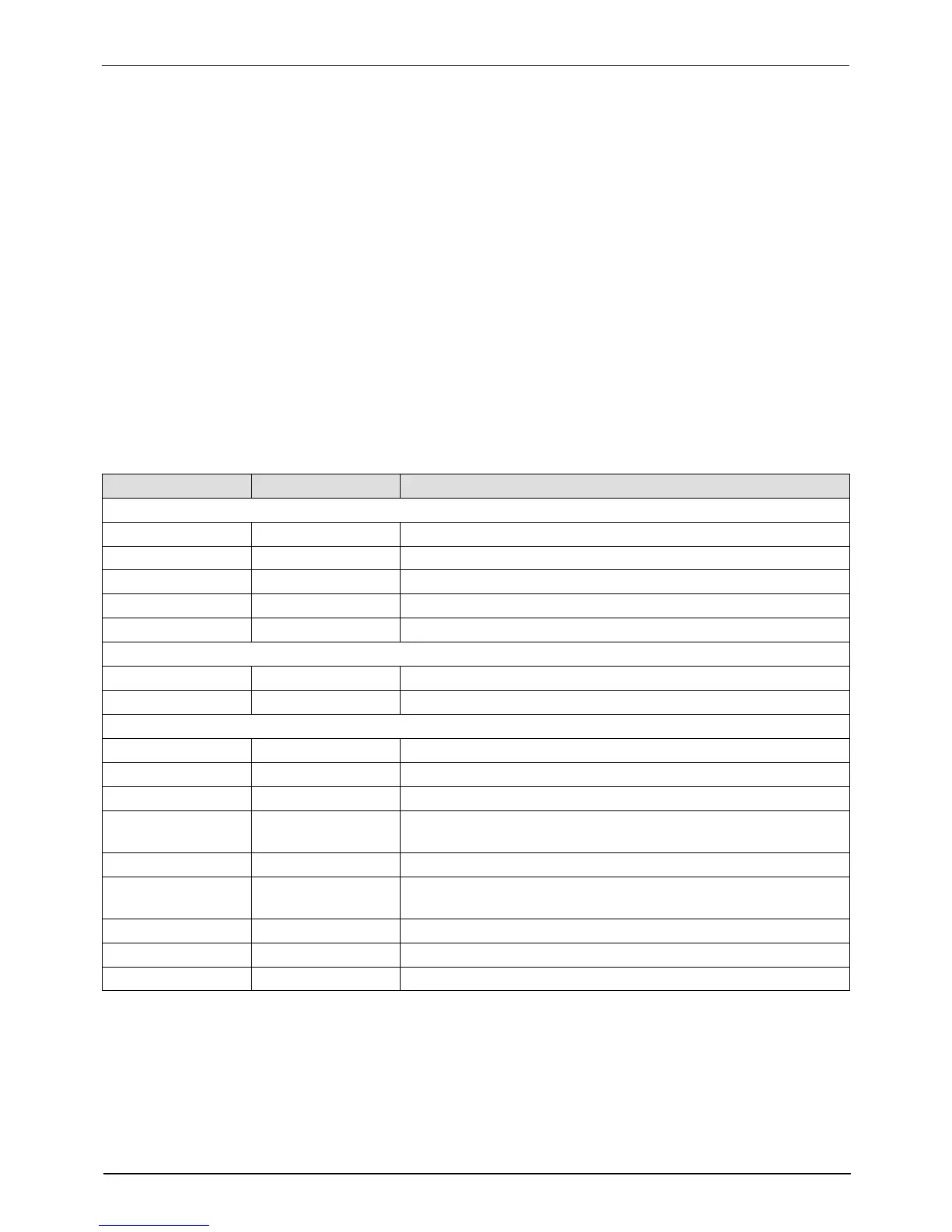

Table 6‐2 Main PCA

Item Number Type Description

Indicators

DS1 LED (Yellow) Control signal for tank heater

DS2 Neon (Orange) Power available for tank and manifold heaters after fuses F1/F2

DS3 LED (Yellow) Control signal for manifold heater

DS4 Neon (Orange) Power available into main board after fuses F3/F4

DS5 LED (Green) +5 VDC control voltage present on board

Fuses

F1/F2 — 15 A, 250 V, Fast‐acting,

1

/

4

inch

F3/F4 — 2 A, 250 V, Slow‐blow, 5 x 20 mm

Connection Points

J1/J2 Jumper Voltage configuration plug with and without neutral

TB1 Input AC power into board

TB2 Input/output Output contacts 1–6. Input contacts 7–14

J5 Input/output Control signal between main board and 6‐hose expansion

board

J6 Output Power harness for tank and manifold heaters

J7 Input/Output Control signal harness (RTD, control switch, thermostat,

solenoid). See Figure 6‐2 for pin‐out.

J8 Input/Output Analog/digital signal cable

J9 Output Control signal to 400/480 VAC transformer

J10 Input AC power out to 6‐hose expansion board

Loading...

Loading...