278 Rockwell Automation Publication 2080-UM002L-EN-E - November 2021

Appendix F PID Function Blocks

How to Autotune Before you autotune, you need to:

• Verify that your system is constant when there is no control. For

example, for temperature control, process value should remain at room

temperature when there is no control output.

• Configure the set point to 0.

• Set Auto Input to False.

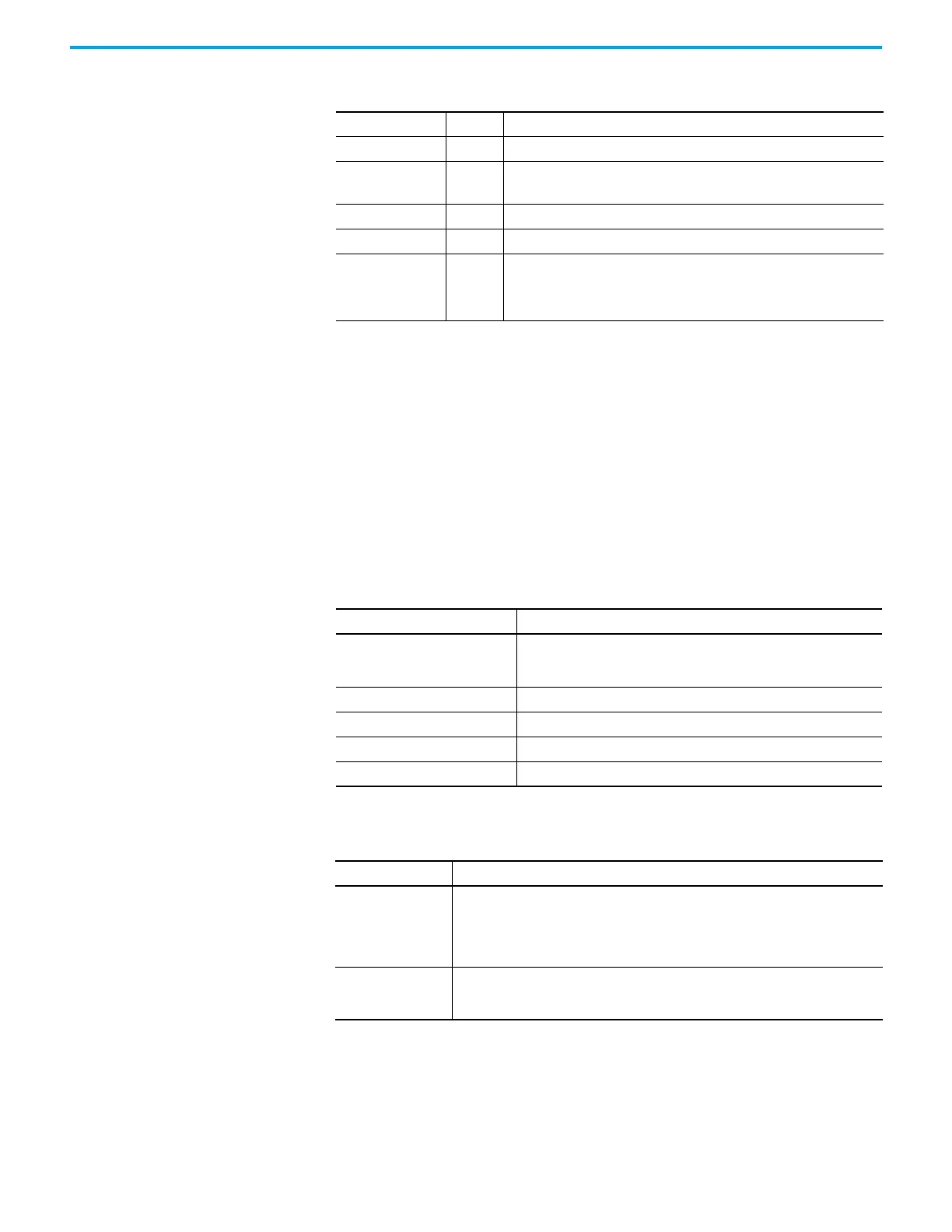

• Set the Gain parameter as follows:

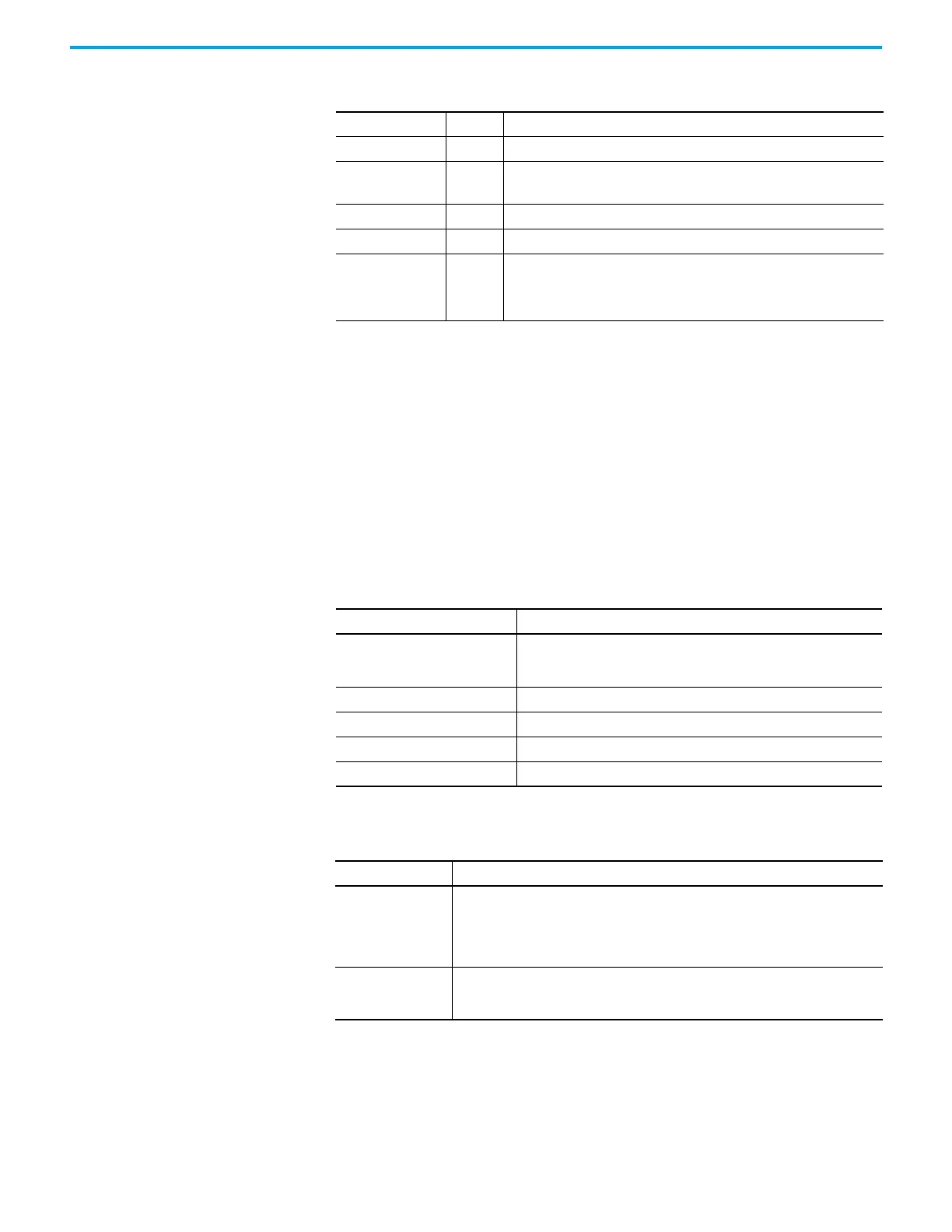

• Set the AT_Parameter as follows:

Table 63 - AT_Param Data Type

Parameter Type Description

Load REAL Load parameter for auto tuning. This is the output value when starting AutoTune.

Deviation REAL

Deviation for auto tuning. This is the standard deviation used to evaluate the

noise band needed for AutoTune (noise band = 3* Deviation)

(1)

(1) The application engineer can estimate the value of ATParams.Deviation by observing the value of Process input. For example, in a

project that involves the control of temperature, if the temperature stabilizes around 22 °C, and a fluctuation of 21.7…22.5 °C is

observed, the value of ATParams.Deviation will be (22.5…21.7)/2=0.4.

Step REAL Step value for AutoTune. Must be greater than noise band and less than ½ load.

ATDynamSet REAL Waiting time in seconds before abandoning auto tune.

ATReset BOOL

Determines whether the output value is reset to zero after an AutoTune

sequence:

TRUE = Reset output to zero.

FALSE = Leaves output at Load value.

Table 64 - GAIN Parameter Values

GAIN Parameter Value

DirectActing

According to operation:

TRUE (for example, Cooling), or

FALSE (for example, Heating)

DerivativeGain 0.5

ProportionalGain 0.0001

TimeIntegral 0.0001

TimeDerivative 0.0

Table 65 - AT_Parameter Values

AT Parameter Recommendation

Load

Every ‘Load’ provides a saturated process value over a period of time. Adjust the load to the

value for the saturated process value you want.

IMPORTANT: If a load of 40 gives you a process value of 30 °C over a period of time, and you

want to tune your system to 30 °C, you should set the load to 40.

Deviation

This parameter plays a significant role in the autotune process. The method of deriving this

value is explained later in this section. It is not necessary to set this parameter prior to

autotuning. However, if you already know the deviation, it is fine to set it first.

Loading...

Loading...