Rockwell Automation Publication 2080-UM002L-EN-E - November 2021 77

Chapter 7

Motion Control

Generally two types of motion control are used in Micro800 controller motion

applications that have Kinetix 3 servo drives.

• Indexed Motion – Micro800 controller issues position

indexes to the

servo drive

using Modbus RTU communications or discrete I/O. Used for

simple positioning. See publication CC-QS025

for building block

example.

• PTO Motion – Micro800 controller uses pu

lse and direction outputs to

the servo drive for precise control of position and v

elocity with Modb

us

RTU

communications or discrete I/O for feedback. Micro800

motion

configuration and instructions make programming easy. See

publication

CC-QS033

for building block example.

PTO Motion Control Certain Micro830, Micro850, and Micro870 controllers, shown in Table 6,

support motion control through high-speed pulse-train outputs (PTO). PTO

functionality refers to the ability of a controller to accurately generate a

specific number of pulses at a specified frequency. These pulses are sent to a

motion device, such as a servo drive, which in turn controls the number of

rotations (position) of a servo motor. Each PTO is exactly mapped to one axis,

to allow for control of simple positioning in stepper motors and servo drives

with pulse/direction input.

As the duty cycle of the PTO can be changed dynamically, the PTO can also be

used as a pulse width modulation (PWM) output.

PTO/PWM and motion axes support on the Micro830, Micro850, and Micro870

controllers are summarized below.

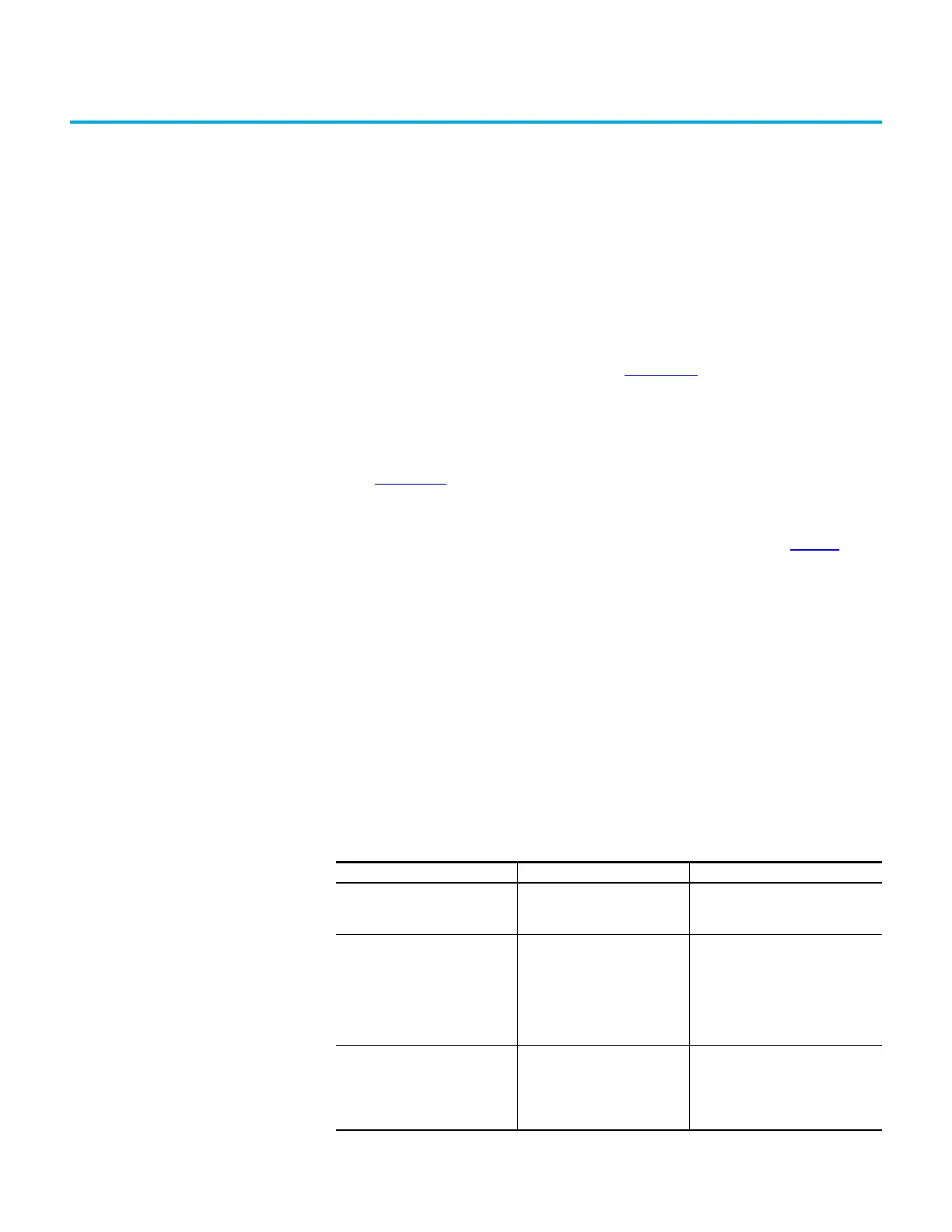

Table 6 - PTO/PWM and Motion Axis Support on Micro830, Micro850, and Micro870

Controller PTO (built-in) Number of Axes Supported

10/16 Points

(1)

2080-LC30-10QVB

2080-LC30-16QVB

(1) For Micro830 catalogs, Pulse Train Output functionality is only supported from firmware revision 2 and later.

11

24 Points

2080-LC30-24QVB

(1)

2080-LC30-24QBB

(1)

2080-LC50-24QVB

2080-LC50-24QBB

2080-LC70-24QBB

2080-LC70-24QBBK

22

48 Points

2080-LC30-48QVB

(1)

2080-LC30-48QBB

(1)

2080-LC50-48QVB

2080-LC50-48QBB

33

Loading...

Loading...