47

(numerator) high

bit*10000

Group 2 Electronic

gear ratio

(denominator) low

bit*1

Group 2 Electronic

gear ratio

(denominator) high

bit*10000

Note: P0-11~P0-14 is all about the parameters of electronic gear ratio, P0-11, P0-12 is group 1, P0-13,

P0-14 is group 2, but the priority of P0-11 and P0-12 is higher than that of P0-13 and P0-14. Only

when P0-11 and P0-12 are set to 0, the ratio of electronic gear P0-13 and P0-14 will take effect. When

P0-11, P0-12, P0-13 and P0-14 are all set to 0, P0-92, P0-93, P0-94 and P0-95 will take effect.

The "electronic gear" function has two main applications: one is to adjust the number of command

pulses required by the motor to rotate one turn to ensure that the motor speed can meet the required

speed. For example, the maximum pulse frequency of the upper computer PLC is 200 KHz. If the

electronic gear ratio is not modified, the motor needs 10,000 pulses to rotate one circle, then the

maximum speed of the motor is 1200 rpm. If the ratio of the electronic gear is 131072:5000, or the

number of pulses per revolution is 5000, then the motor can reach 2400 rpm speed.

Take 17-bit encoder motor as an example: the ratio of electronic gears is 131072:10000 or the

number of pulses per revolution is 10000, and the highest frequency of pulse transmitted by PLC is 200

KHz.

Electronic gear ratio is 131072:5000 or pulses per rotation is 5000, PLC max output pulse

frequency is 200KHz.

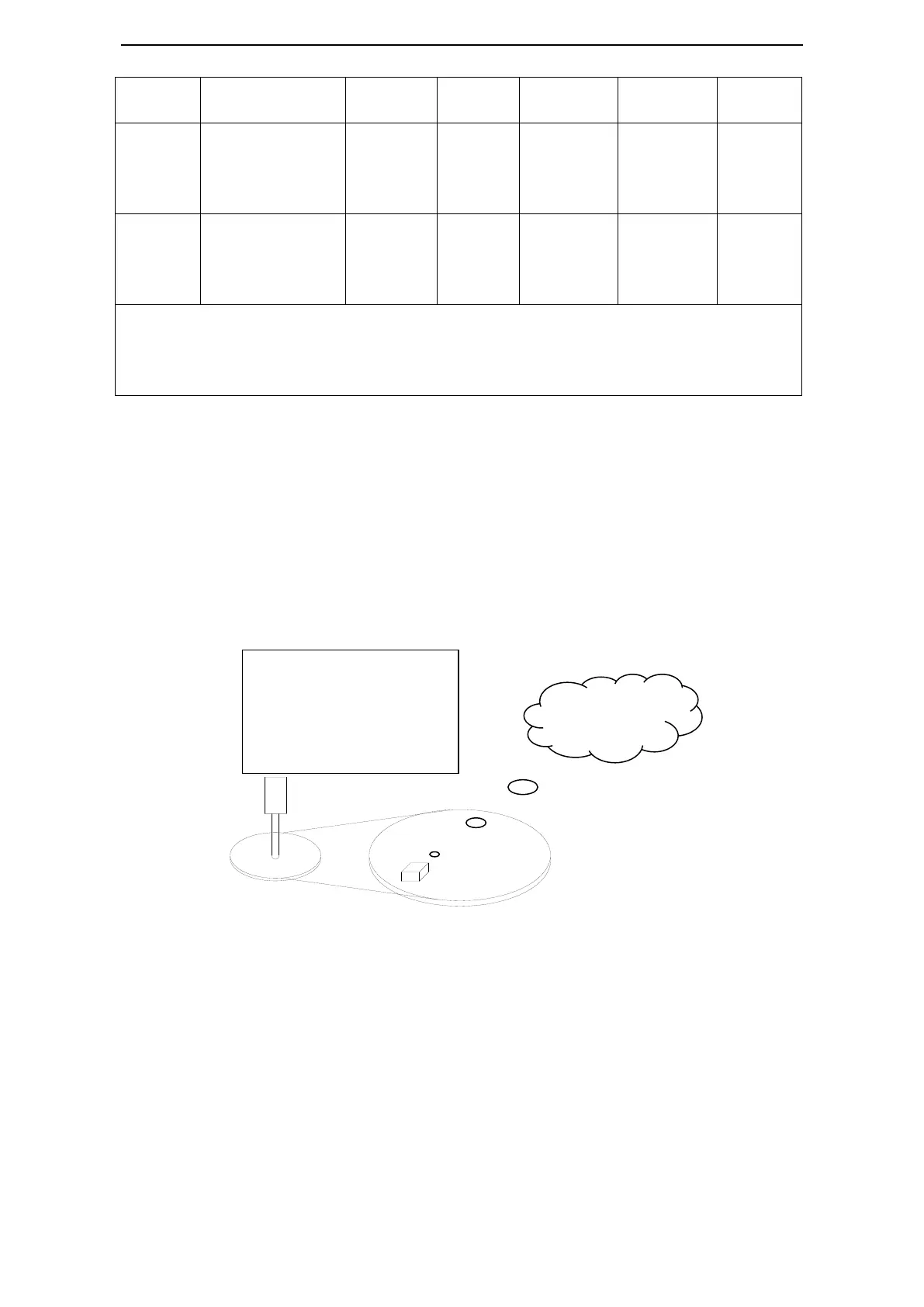

Two circle radius ratio: 2:1

Big circle run one rotation

(need 20000 pulses), small

circle run two rotations.

Loading...

Loading...