Maintenance 7 - 3

Preventive Maintenance

If the Drive is used under the following conditions, it may be necessary to inspect more often:

• High ambient temperatures, humidity or altitudes above 3,300 feet.

• Frequent starting and stopping.

• Fluctuations of the AC power supply or load.

• Excessive vibration and/or shock loading.

• Poor environment, including dust, metal dust, salt, sulfuric acid, chlorine.

• Poor storage conditions.

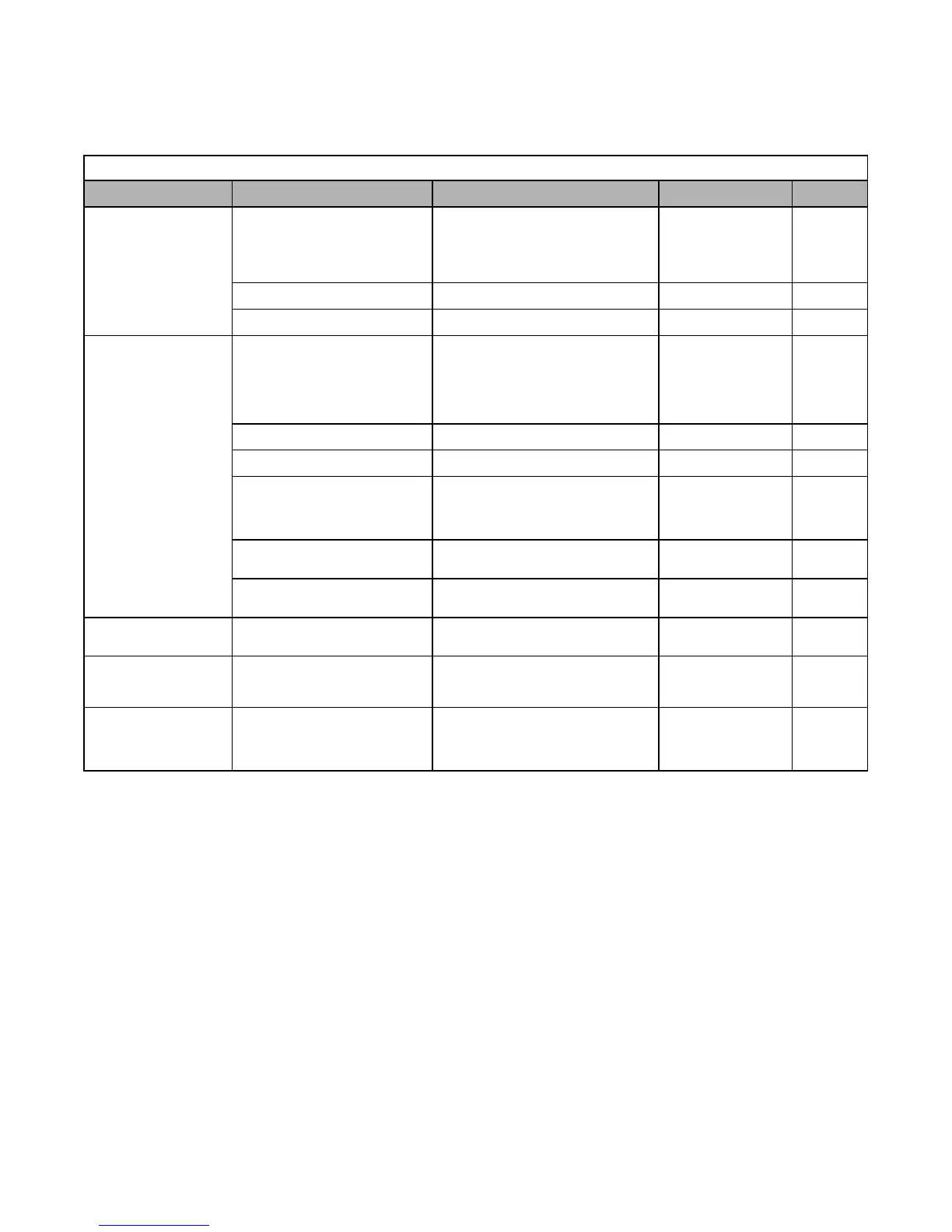

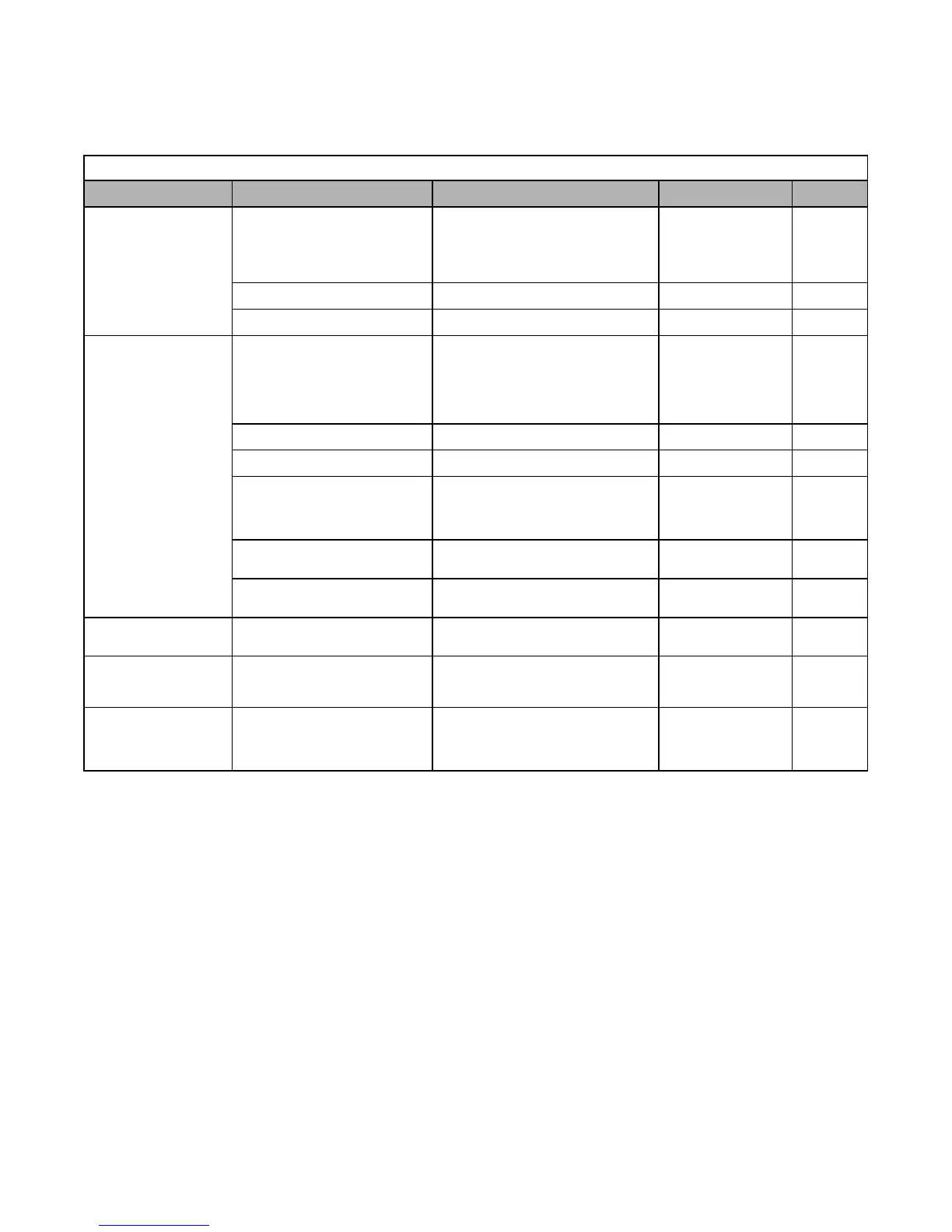

Table 7.3 Preventive Maintenance

Inspection Points Item Check Points Every 3-6 Months Yearly

General

Environment

Ambient temperature

Humidity

Dust

Harmful gas

Oil mist

X

X

X

X

X

Equipment Abnormal vibration or noise X

AC Power Supply Main circuit & control voltage X

AC Power Circuit &

Devices

Conductors & Wire

Connections

Loose lugs, screws & wires

Hot spots on parts

Corrosion

Bent conductors

Breakage, cracking or discoloration

Check spacing

X

X

X

X

X

X

Transformers & Reactors Discoloration or noise X

Terminal Blocks Loose, damaged X

DC Bus Capacitors

Leakage

Ruptures, broken, expansion

Capacitance & insulation

resistance

X

X

X

Relays & Contactors

Noisy

Contact discoloration

X

X

Soft Charge Resistors

Cracked

Discoloration

X

X

Control Circuits Operation

Speed reference voltage/current

I/O contact operation

X

X

Cooling System Cooling Fans/Fins & Heatsink

Abnormal fan noise

Loose connectors

Free of accumulation

X

X

X

Keypad/Display Digital Operator

LEDs

Monitor display values

Key functionality

Clean

X

X

X

X

Email: Sales@aotewell.com

Loading...

Loading...