Electrical Installation 2 - 8

The use of UL listed closed-loop connectors or CSA certified ring connectors sized for the selected wire gauge is

recommended to maintain proper clearances when wiring the Drive. Install connectors per manufacturer recom-

mendation using the correct crimp tool. Table 2.3 lists a suitable closed-loop connector manufactured by JST Cor-

poration.

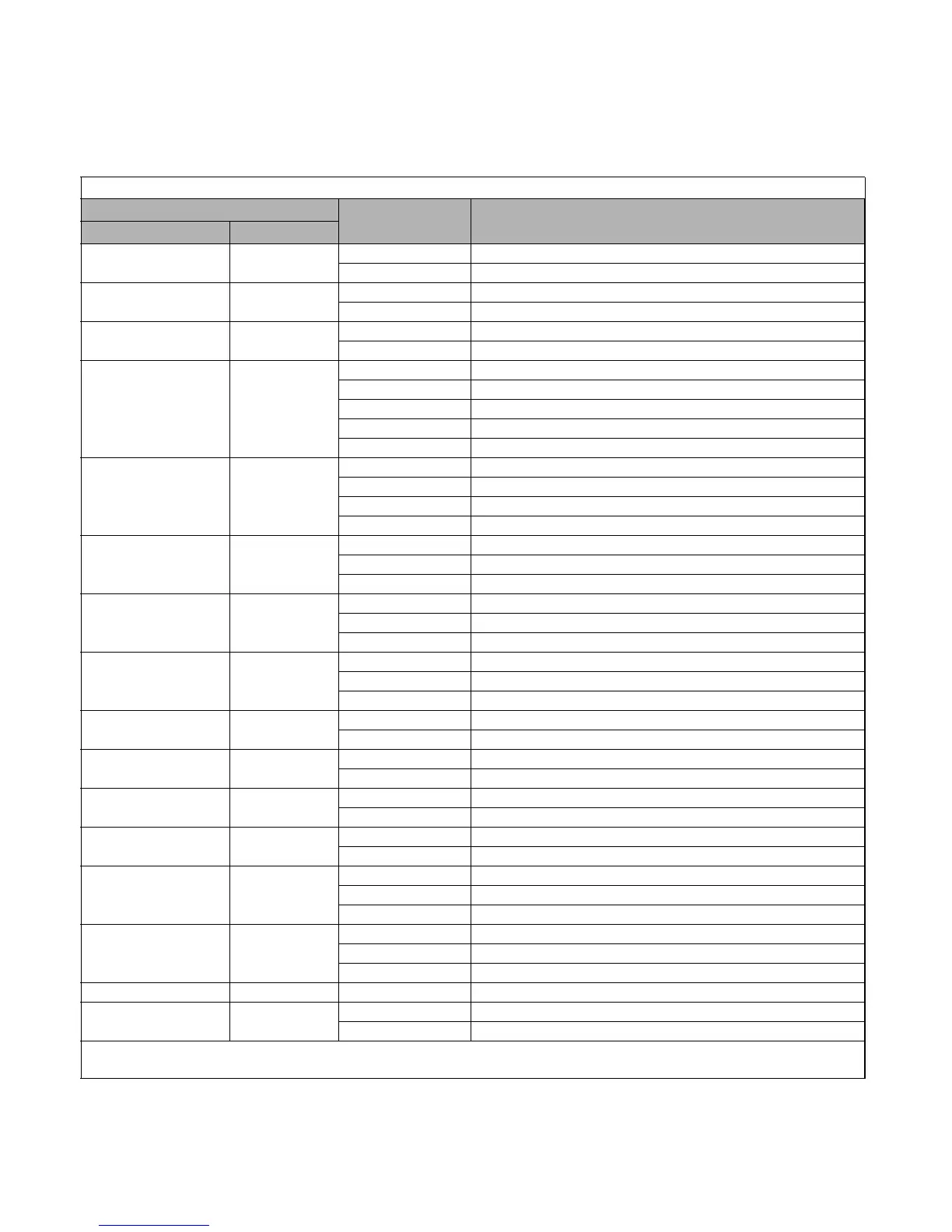

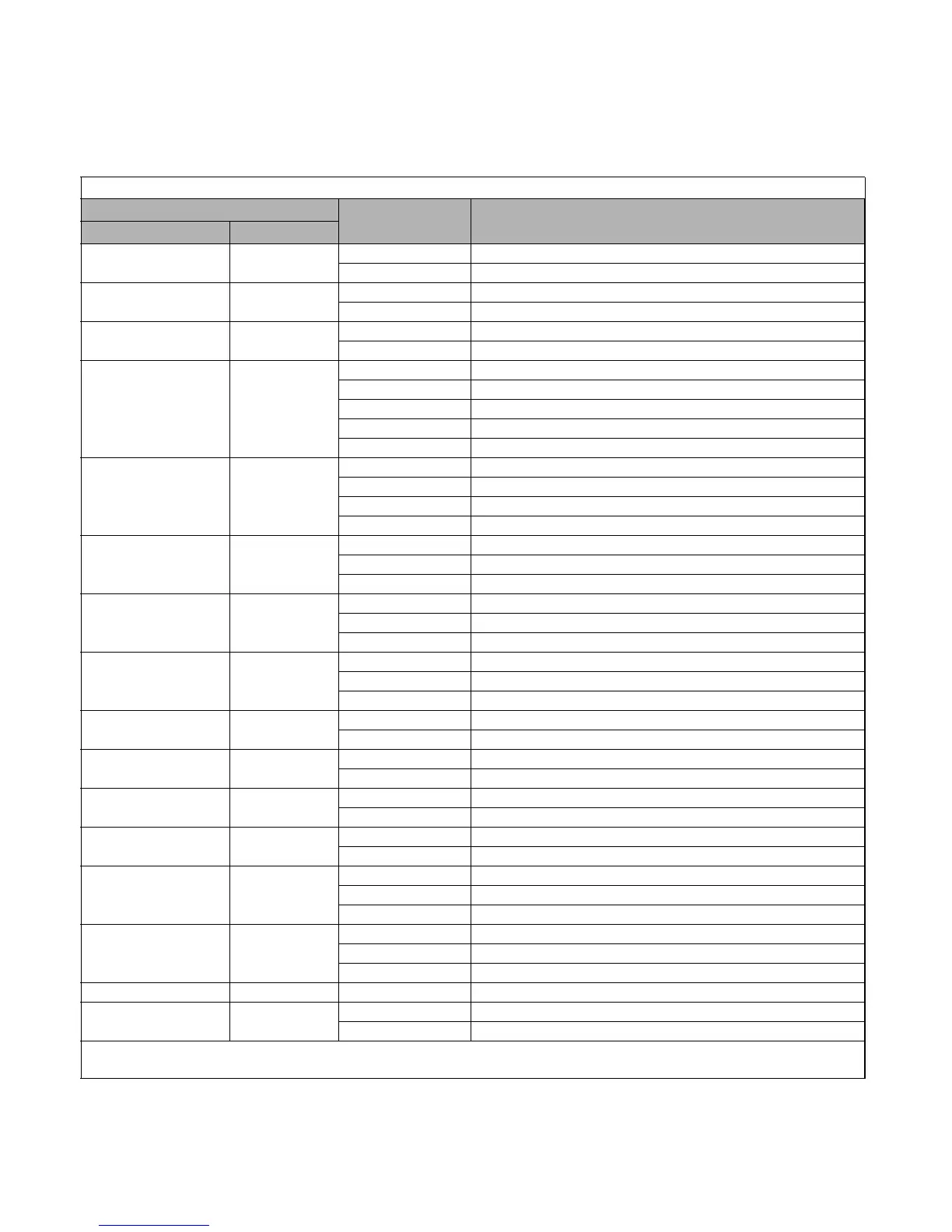

Table 2.3 Recommended Connectors for Terminal Connections

Wire Size *

Terminal Screw

Ring Tongue (R-Type) Closed-Loop Connectors (Lugs)

JST Corporation Part Numbers **

AWG mm

2

20 0.5

M3.5 1.25 - 3.7

M4 1.25 - 4

18 0.75

M3.5 1.25 - 3.7

M4 1.25 - 4

16 1.25

M3.5 1.25 - 3.7

M4 1.25 - 4

14 2

M3.5 2 - 3.7

M4 2 - 4

M5 2 - 5

M6 2 - 6

M8 2 - 8

12 / 10 3.5 / 5.5

M4 5.5 - 4

M5 5.5 - 5

M6 5.5 - 6

M8 5.5 - 8

88

M5 8 - 5

M6 8 - 6

M8 8 - 8

614

M5 14 - 5

M6 14 - 6

M8 14 - 8

422

M5 22 - 5

M6 22 - 6

M8 22 - 8

3 / 2 30 / 38

M6 38 - 6

M8 38 - 8

1 / 1/0 50 / 60

M8 60 - 8

M10 60 - 10

2/0 70

M8 70 - 8

M10 70 - 10

3/0 80

M10 80 - 10

M16 80 - 16

4/0 100

M10 100 - 10

M12 100 - 12

M16 100 - 16

250 / 300MCM 125 / 150

M10 150 - 10

M12 150 - 12

M16 150 - 16

400MCM 200 M12 200 - 12

650MCM 325

M12 x 2 325 - 12

M16 325 - 16

* Wire sizes are based on 75 degrees Celsius copper wire.

** Equivalent connector can be used.

Email: Sales@aotewell.com

Loading...

Loading...