Loading...

Loading...

Do you have a question about the Belarus 3522.5 and is the answer not in the manual?

Lists key parameters and technical data of the tractor.

Presents the arrangement of controls and instruments located within the tractor cab.

Provides information on operational parameters and system failures via gauges and lamps.

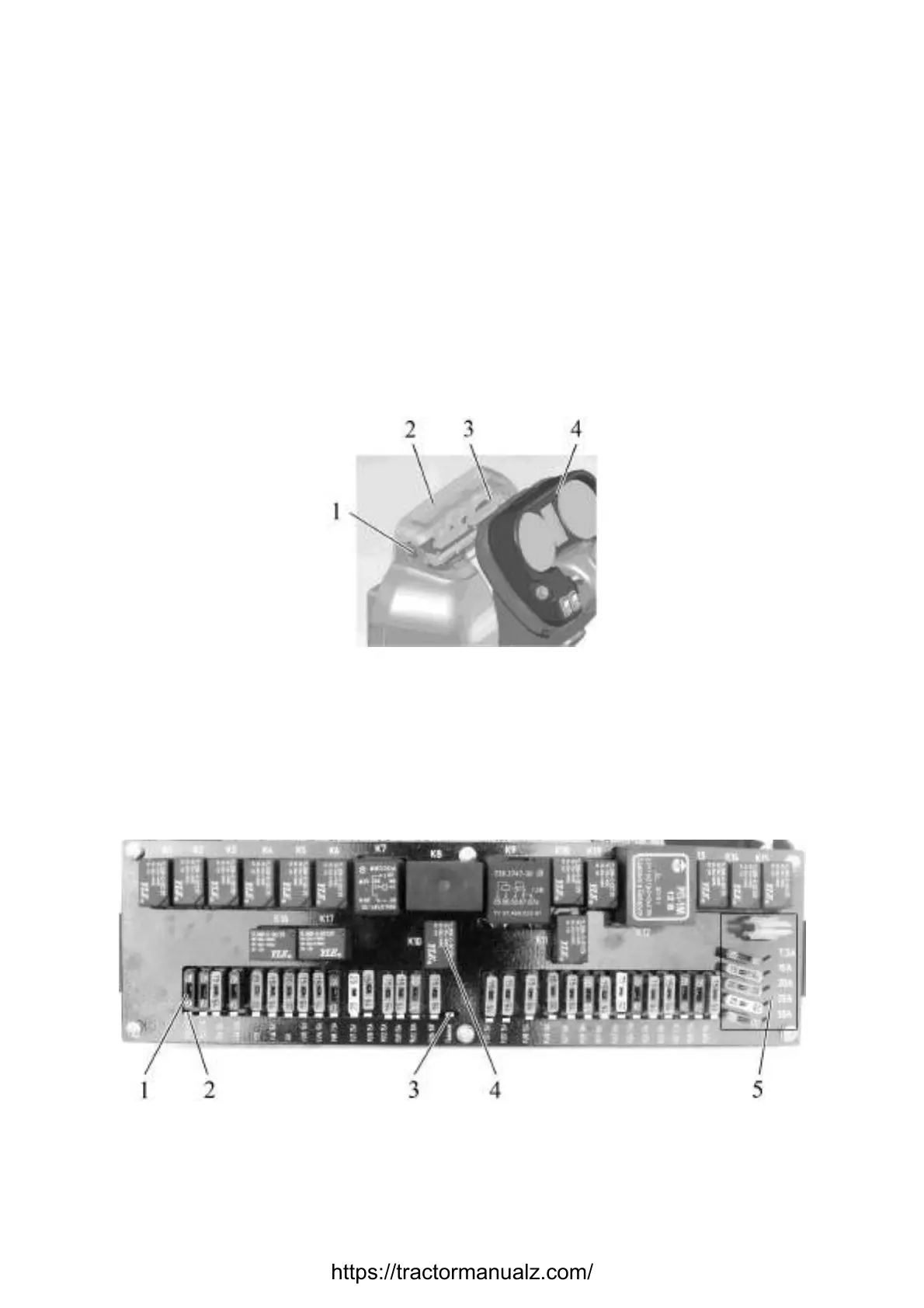

Covers general information on hydrostatic steering control and reverse valve switch.

Details the process of switching gearbox ranges, creeper control, and CECS.

Outlines the functions and components of the CECS.

Covers the EHS electronic system, joysticks, OPU, and flow restriction.

Explains the EECS, its components, and its function in engine operation.

Covers the gearbox structure, speed unit, and range shifting mechanisms.

Explains the components of the rear axle, including main gear, differential, and final drives.

Covers general information on the disk brakes and their service control.

Presents the hydraulic circuit diagram and component locations for transmission systems.

Details the front driving axle, including its central reduction unit and wheel hub drives.

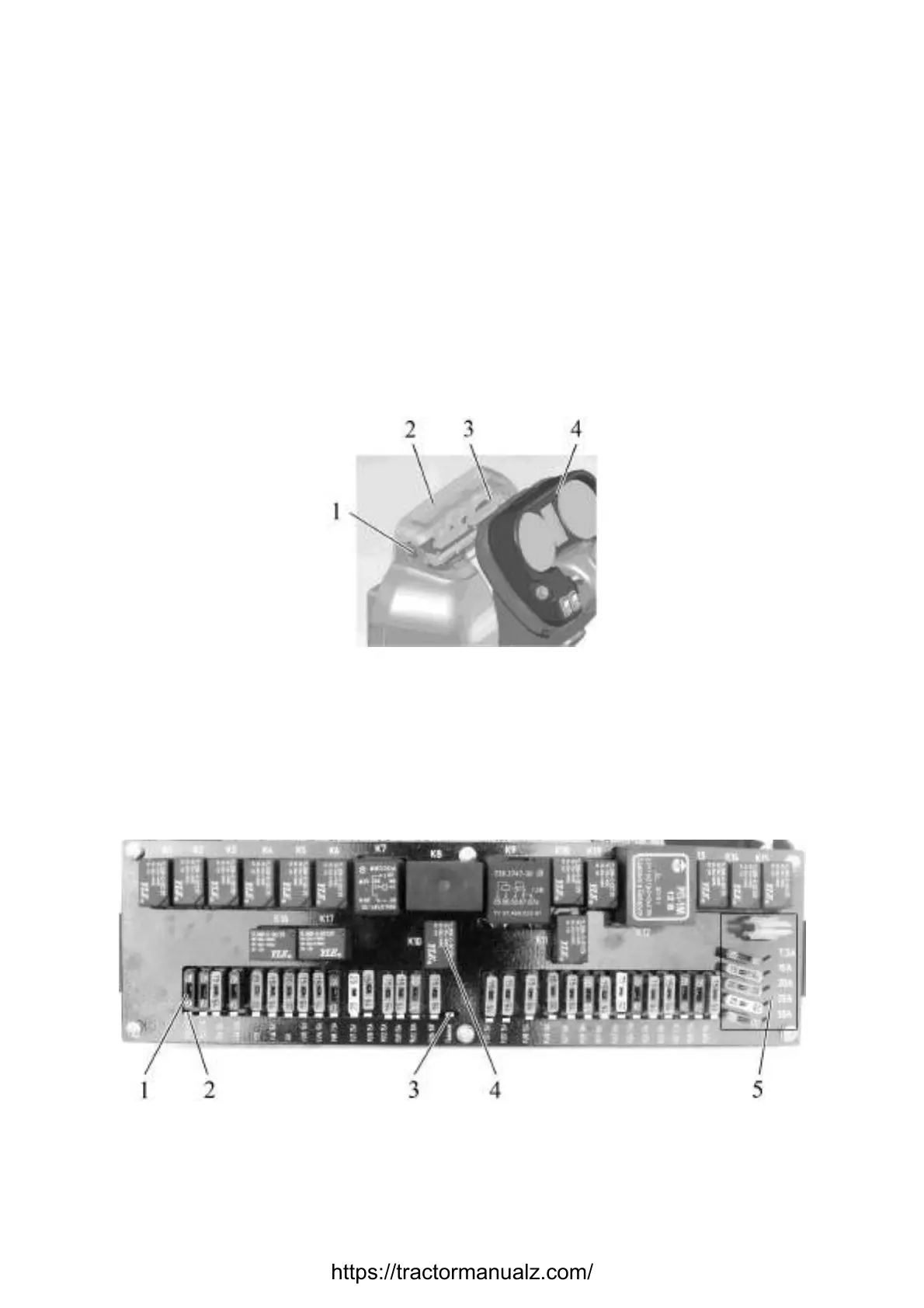

Covers the electronic control systems for differential lock, FDA, and PTO shafts.

Explains the HSC system, dosing pumps, and steering hydraulic cylinders.

Details the HLL system, its components, and hydraulic circuit diagrams.

Explains the electronic control system for the rear lift linkage and its components.

Provides essential instructions and warnings to be read before tractor use.

Details general safety measures, fire safety, and precautions for operation.

Outlines procedures for stopping the tractor, engine emergency stop, and accident response.

Provides general guidelines for all maintenance services, emphasizing engine manual for details.

Details maintenance tasks based on operating hours (shift, 125, 250, 500, 1000 hours).

Provides essential safety requirements for performing maintenance and repair services.

Lists possible failures in electronic systems for gearbox, axles, PTO, and troubleshooting methods.

Details possible hydraulic system failures for RLL/FLL control and troubleshooting guidelines.

Covers EHS distributor failures, indication, causes, and troubleshooting steps.

Provides guidelines for troubleshooting electrical equipment failures.