139

4) Apply heat resistant grease sliding surface.

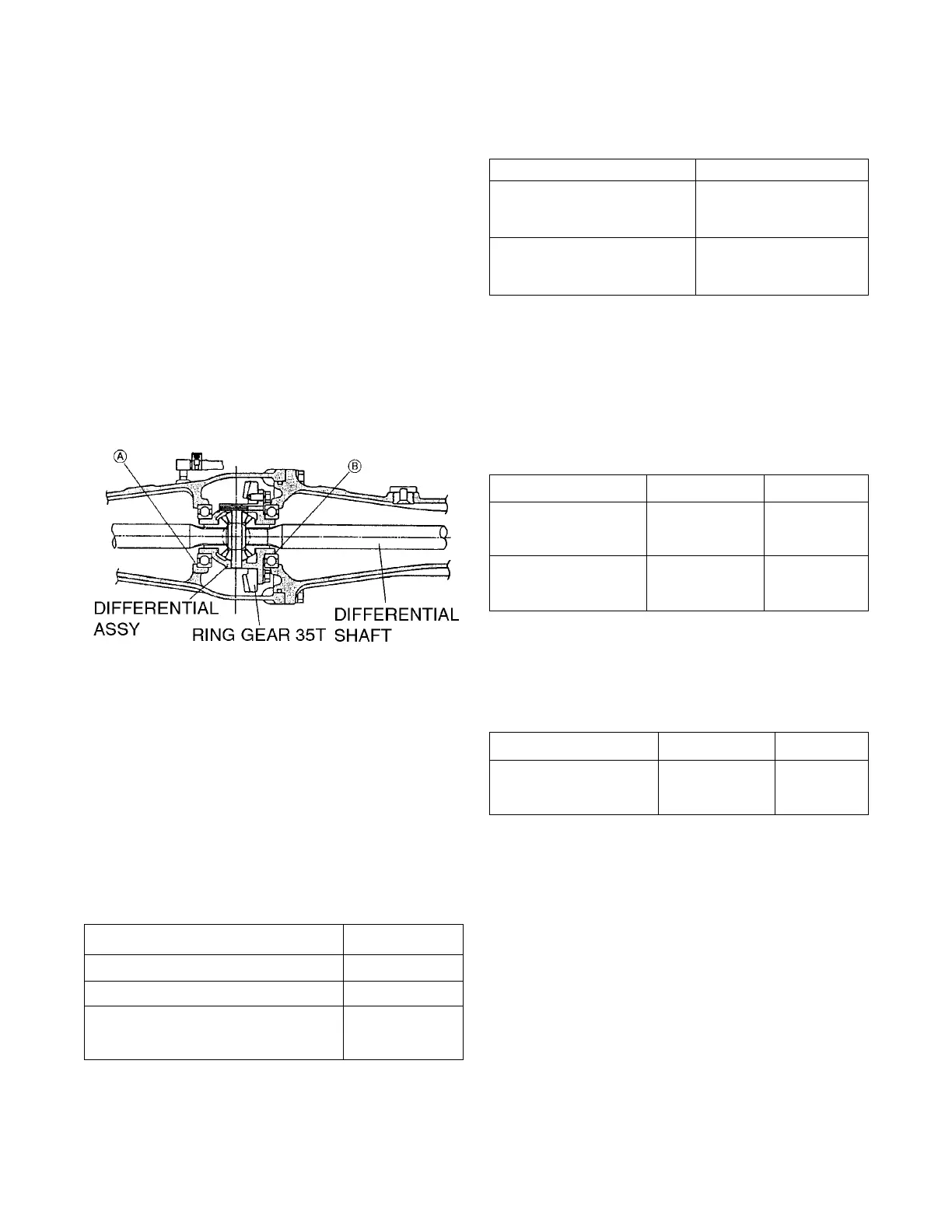

4. Diff. case installation

1) Adjust the backlash between ring gear and

pinion shaft to [0.0098~0.0138 in.] by liner at

(A).

2) Adjust end play of diff. case assy to

[0~0.004 in.] by liner at (B).

8-3. FRONT AXLE CHECK AND

MAINTENANCE

(1) BACKLASH

1. Check the backlash of diff. case assy and end

play. In case that the measurement value is

out of standard, readjust it.

Item

Standard value (in.)

Backlash of side gear and pinion 0.004~0.012

End play of diff. assy 0~0.004

Backlash between pinion 0.0098~

shaft and ring gear 0.0138

2. Check the backlash of bevel gears. In case

that the backlash is out of standard, readjust it.

Item Standard value (in.)

Backlash between bevel 0.008~0.0157

gear14T and 18T

Backlash between bevel 0.008~0.0157

gear 13T and 38T

(2) CLEARANCE AT BUSHING

1. Check the clearance between front bracket /

rear bracket and bushing. In case that the

clearance is out of service limit, replace the

bushing.

Item Standard value(in.) Service limit (in.)

Clearance between 0.0012~0.0026 0.0008

holder and front bracket

Clearance between case 0.0012~0.0032 0.0008

and rear bracket bushing

2. Check the clearance at bushing of final gear

case L.H./R.H.. In case that the clearance is

out of service limit, replace the bushing.

Item

Standard value(in.) Service limit(in.)

Clearance between king 0.00118 0.0079

pin case and bushing ~0.00315

Loading...

Loading...