81

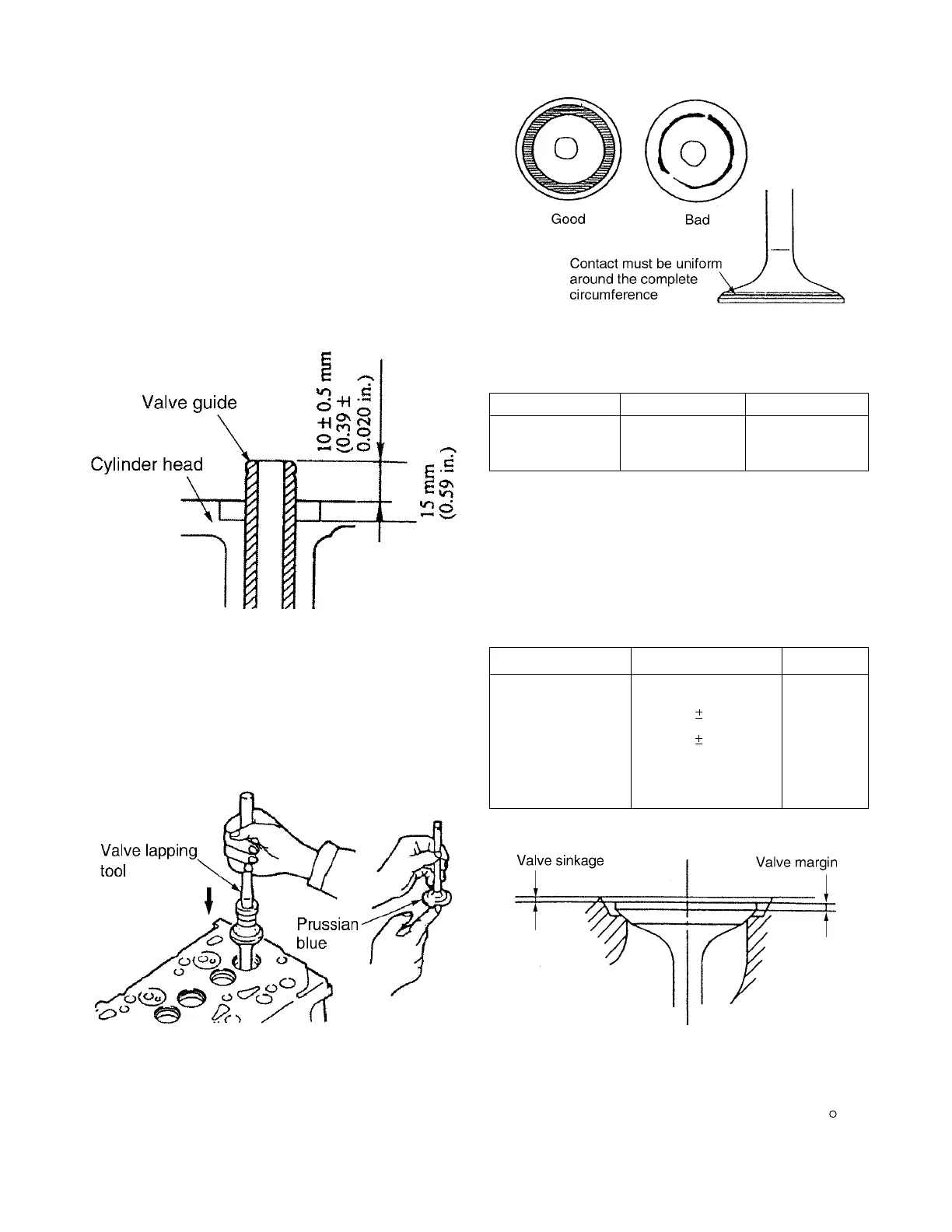

(b)Install a new guide into the cylinder

head by pushing it with an arbor press

from the upper side of the head until the

specified height to the top of the guide

is obtained.

(c)Insert a new valve into the guide and

make sure the valve slides in the guide

freely.

(d)After the valve guide has been replaced,

check the valve contact with its seat.

(4)Valves

(a)Put a small amount of Prussian blue or

read lead on the valve face. Hold the

valve with a valve lapping tool(com-

mercially available)and press it against

the seat to check its contact.

(b)The width of contact must be uniform all

the way around both seat and valve. If

the contact is bad, reface the valve and

seat.

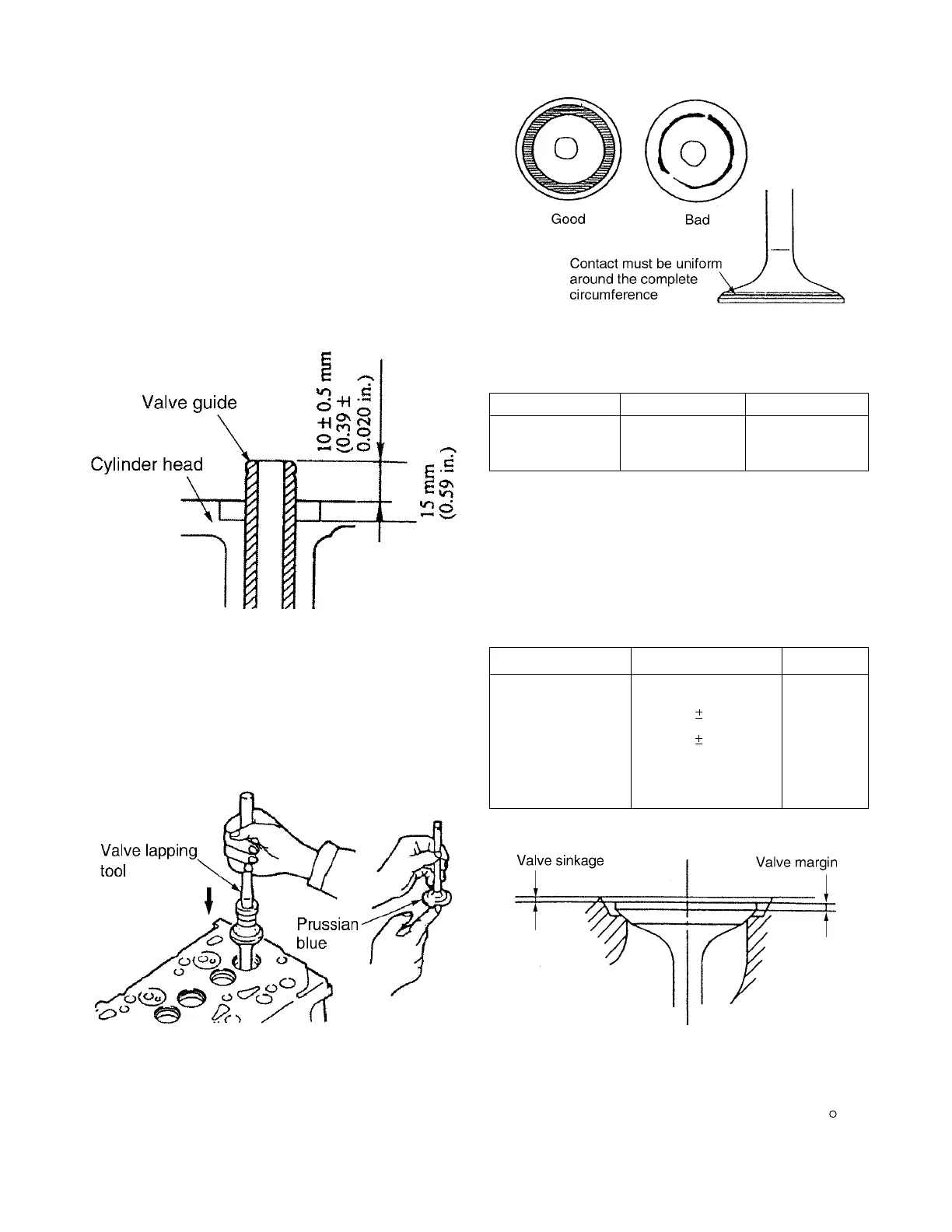

(c)If the valve margin(valve lip thickness)

exceeds the limit, replace the valve.

Unit:mm(in.)

Item Standard Limit

Valve margin 1.0(0.039) 0.5(0.020)

(lip thickness)

(d)If the valve sinkage(the dimension from

the top of a closed valve to the face of

cylinder head)exceeds the limit, recon-

dition the valve seat or replace the

cylinder head assembly.

Unit:mm(in.)

Item Standard Limit

Valve sinkage

(dimension from 0.05 0.25 1.5

top of closed (0.020 0.0098) (0.059)

valve to face

of head)

(5)Valve refacing

(a)Set the valve refacer at an angle of 45

and grind the valve.

Loading...

Loading...