94

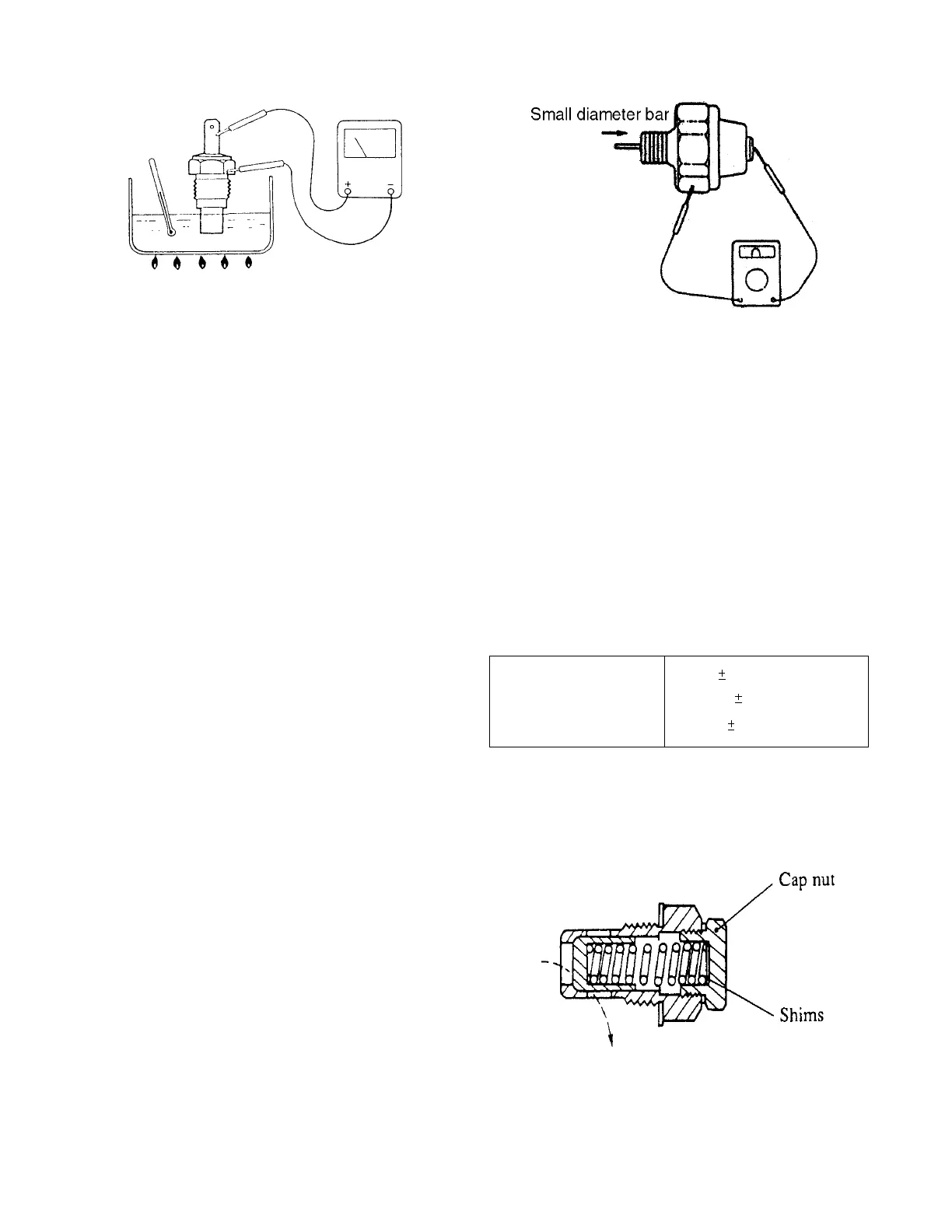

3.Pressure relief valve

(1)Check the valve seat for contact.

Check the spring for damage.

(2)Measure the oil pressure at which the

relief valve opens (the oil pressure with

the engine running at the rated rpm).

If the pressure is not correct, remove the

cap nut increase or decrease the amount of

shims. The engine oil pressure tap is

located on the right side of the engine.

Relief valve 3.5 0.5kgf/cm

2

opening pressure (50 7psi)

[343 49kPa]

(5)LUBRICATION SYSTEM

1.Oil pump

Visually check the pump for rough rotation or

other defects. Replace the pump assembly if

defective.

2.Oil pressure switch

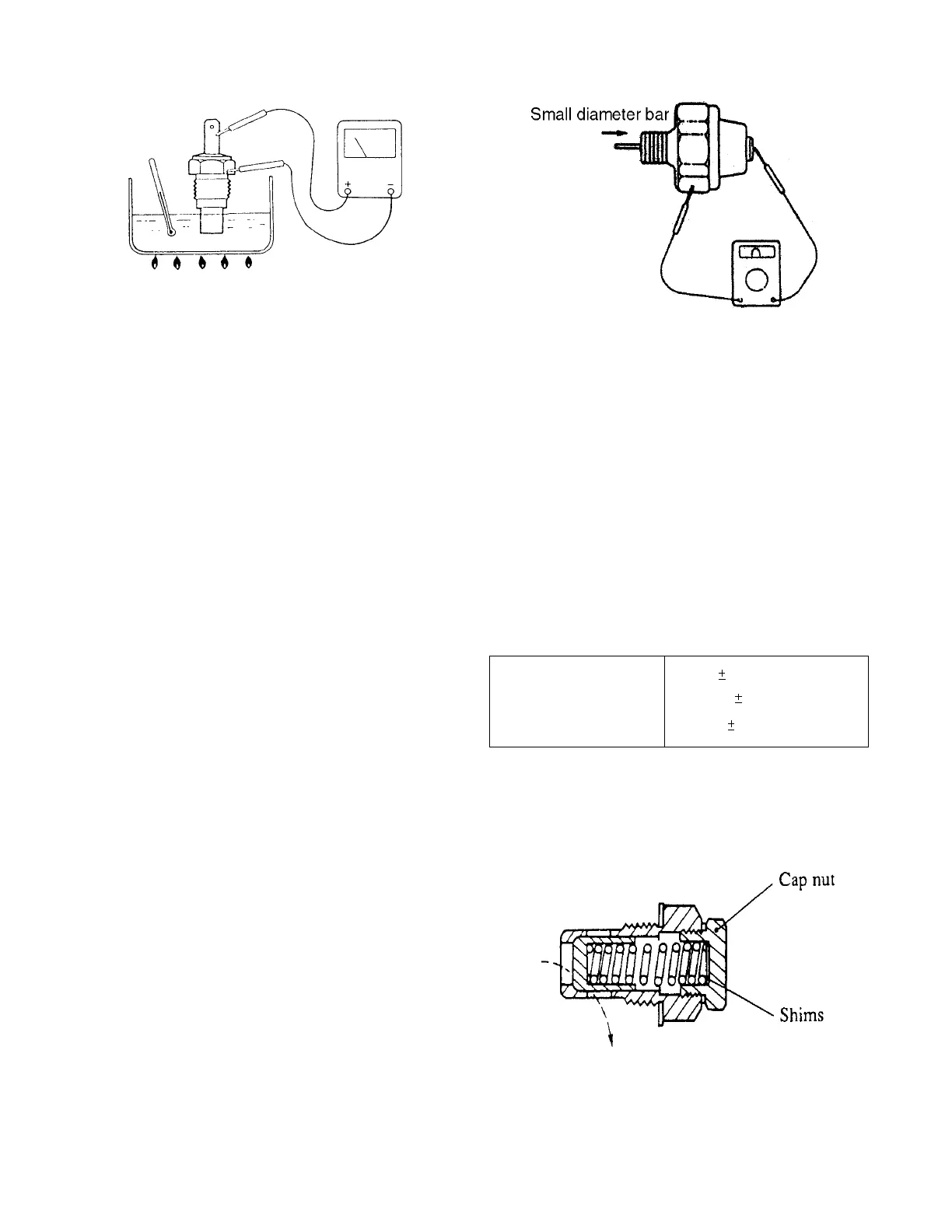

(1)Test for continuity between the terminal

and body with an ohmmeter as shown in the

illustration. No continuity is the cause for

replacing theswitch.

(2)Insert a small diameter bar into the oil hole

in the switch and lightly push it in to test

for no continuity as shown in the illustra-

tion. Any continuity is the cause for

replacing the switch.

(3)Apply a pressure air of 0.5kgf/cm

2

(7psi)

(49kpa)to the switch through the oil

hole to test for no continuity.

Any continuity is the cause for replacing

the switch. Also, check for air leaks.

Any air leak is an indication of a ruptured

diaphragm. In such a case, replace the switch.

Loading...

Loading...