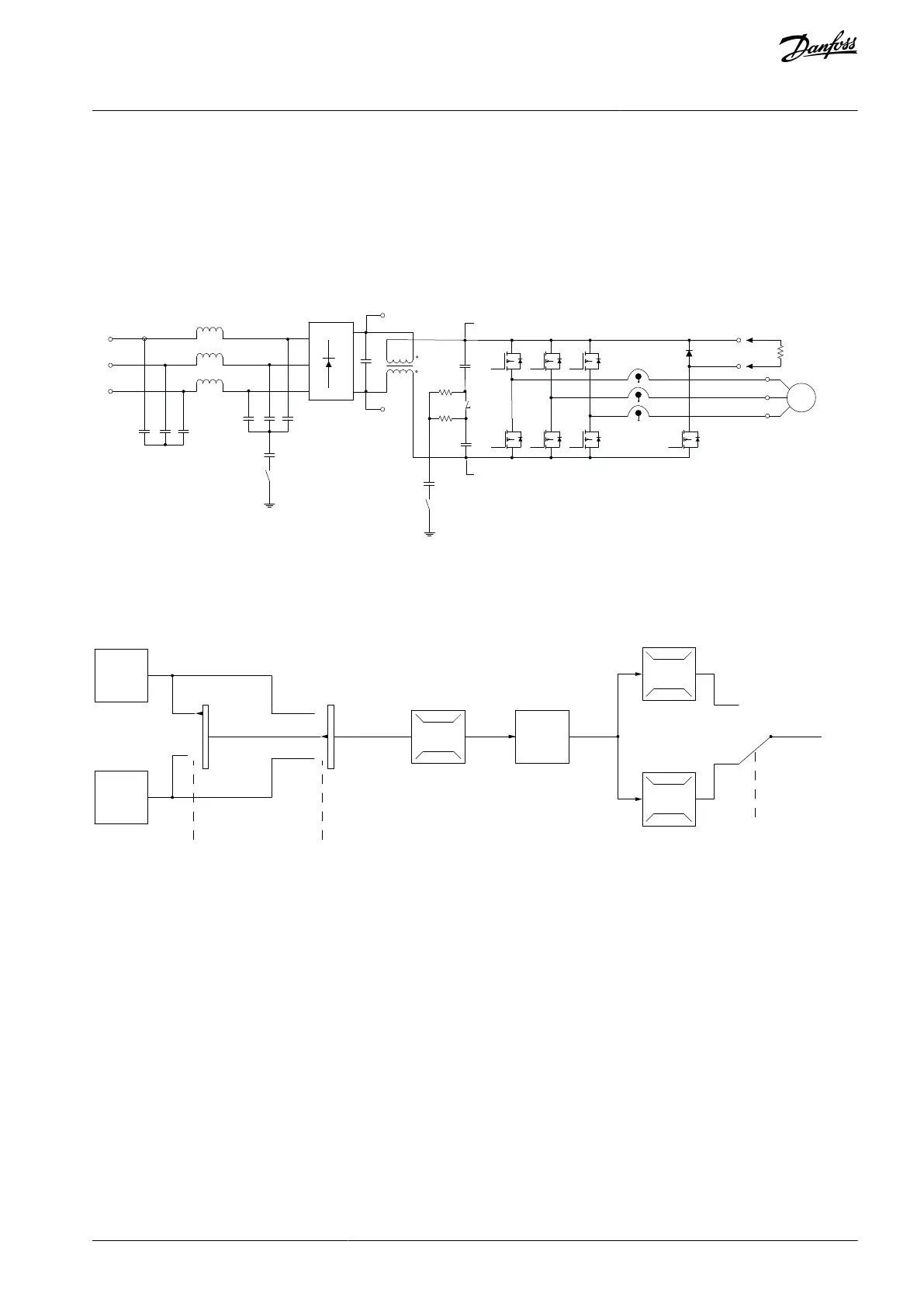

11.4 Control Principle

The drive recties AC voltage from mains into DC voltage, after which the DC voltage is converted into an AC current with a variable

amplitude and frequency.

The drive supplies the motor with variable voltage/current and frequency, standard induction motors, and non-salient PM motors.

The drive manages various motor control principles such as U/f special motor mode and VVC

+

. Short-circuit behavior of the drive

depends on the 3 current transducers in the motor phases.

The VLT® drives can run in open-loop and closed-loop application. Select the conguration mode when programming the drive.

Inrush

R inr

Load sharing -

Load sharing +

LC Filter -

(5A)

Illustration 90: Control Structure Diagram

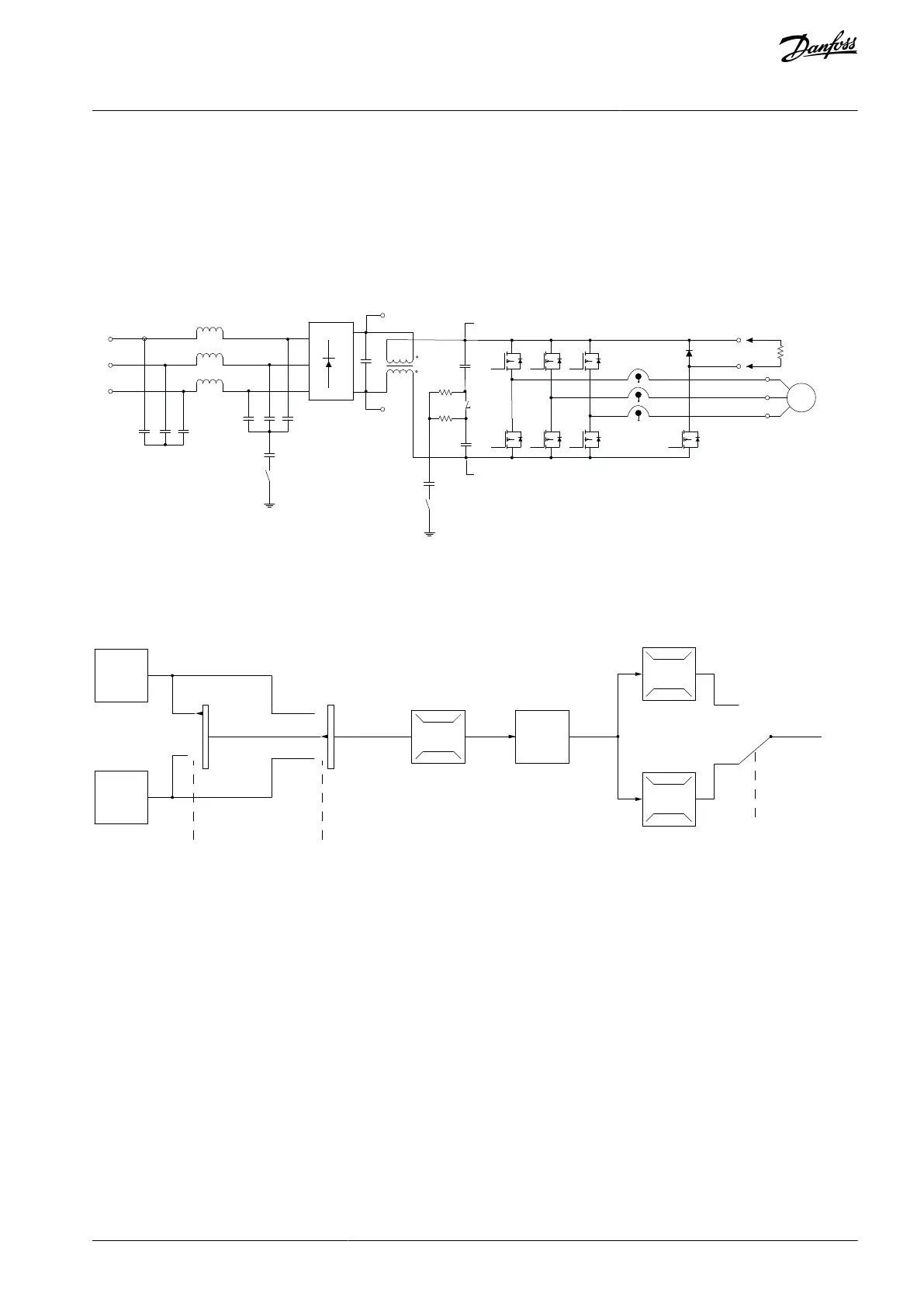

11.4.1 Control Structure Open Loop

100%

P 3-13

Reference

site

Local

reference

scaled to

RPM or Hz

Auto mode

Hand mode

LCP Hand on,

off and auto

on keys

Linked to hand/auto

Local

Reference

Ramp

P 4-10

Motor speed

direction

To motor

control

Reference

handling

Remote

reference

P 4-13

Motor speed

high limit [RPM]

P 4-14

Motor speed

high limit [Hz]

P 4-11

Motor speed

low limit [RPM]

P 4-12

Motor speed

low limit [Hz]

P 3-4* Ramp 1

P 3-5* Ramp 2

Illustration 91: Open-loop Structure

In open-loop congurations, the resulting reference from the reference handling system or the local reference is received and fed

through the ramp limitation and speed limitation before being sent to the motor control.

The output from the motor control is then limited by the maximum frequency limit.

11.4.2 Control Structure Closed Loop

The internal controller allows the drive to become a part of the controlled system. The drive receives a feedback signal from a sensor

in the system. It then compares this feedback to a setpoint reference value and determines the error, if any, between these 2 signals.

It then adjusts the speed of the motor to correct this error.

For example, consider a pump application where the speed of a pump is to be controlled to ensure a constant static pressure in a

pipe. The static pressure value is supplied to the drive as the setpoint reference. A static pressure sensor measures the actual static

pressure in the pipe and supplies this data to the drive as a feedback signal. If the feedback signal is greater than the setpoint refer-

ence, the drive slows the pump down to reduce the pressure. In a similar way, if the pipe pressure is lower than the setpoint refer-

ence, the drive automatically speeds the pump up to increase the pressure provided by the pump.

AJ300847815559en-000101 / 130R0337 | 163Danfoss A/S © 2020.09

Basic Operating Principles

VLT® AQUA Drive FC 202

Design Guide

Loading...

Loading...