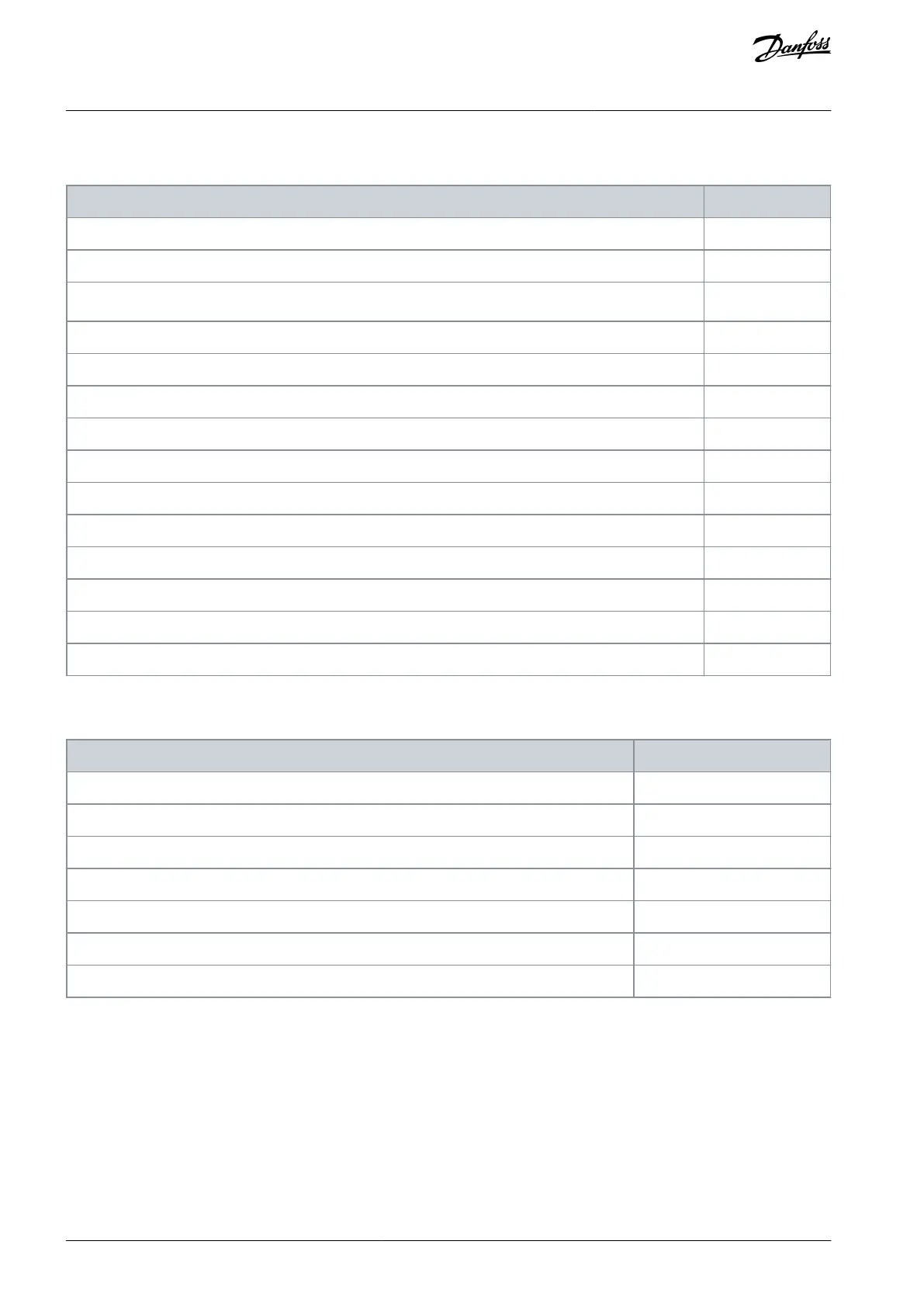

13.2.7 Order Numbers for Local Control Panel Options

Table 131: Order Numbers for Local Control Panels

VLT® LCP 101 Numeric Local Control Pad

VLT® LCP 102 Graphical Local Control Pad

VLT® Wireless Control Panel LCP 103

VLT® Cable for LCP 2, 3 m (9.8 ft)

VLT® Panel Mounting Kit for all LCP types

VLT® Panel Mounting Kit with graphical LCP

VLT® Panel Mounting Kit with numerical LCP

VLT® LCP Mounting Kit, without LCP

VLT® LCP Mounting Kit Blind Cover IP55/66, 8 m (26.2 ft)

VLT® Control Panel LCP 102, graphical

VLT® Blind cover, with Danfoss logo, IP55/66

Remote mounting kit for LCP with cover for outdoor mounting with 3 m (10 ft) cable

Remote mounting kit for LCP with cover for outdoor mounting with 5 m (16 ft) cable

Remote mounting kit for LCP with cover for outdoor mounting with 10 m (33 ft) cable

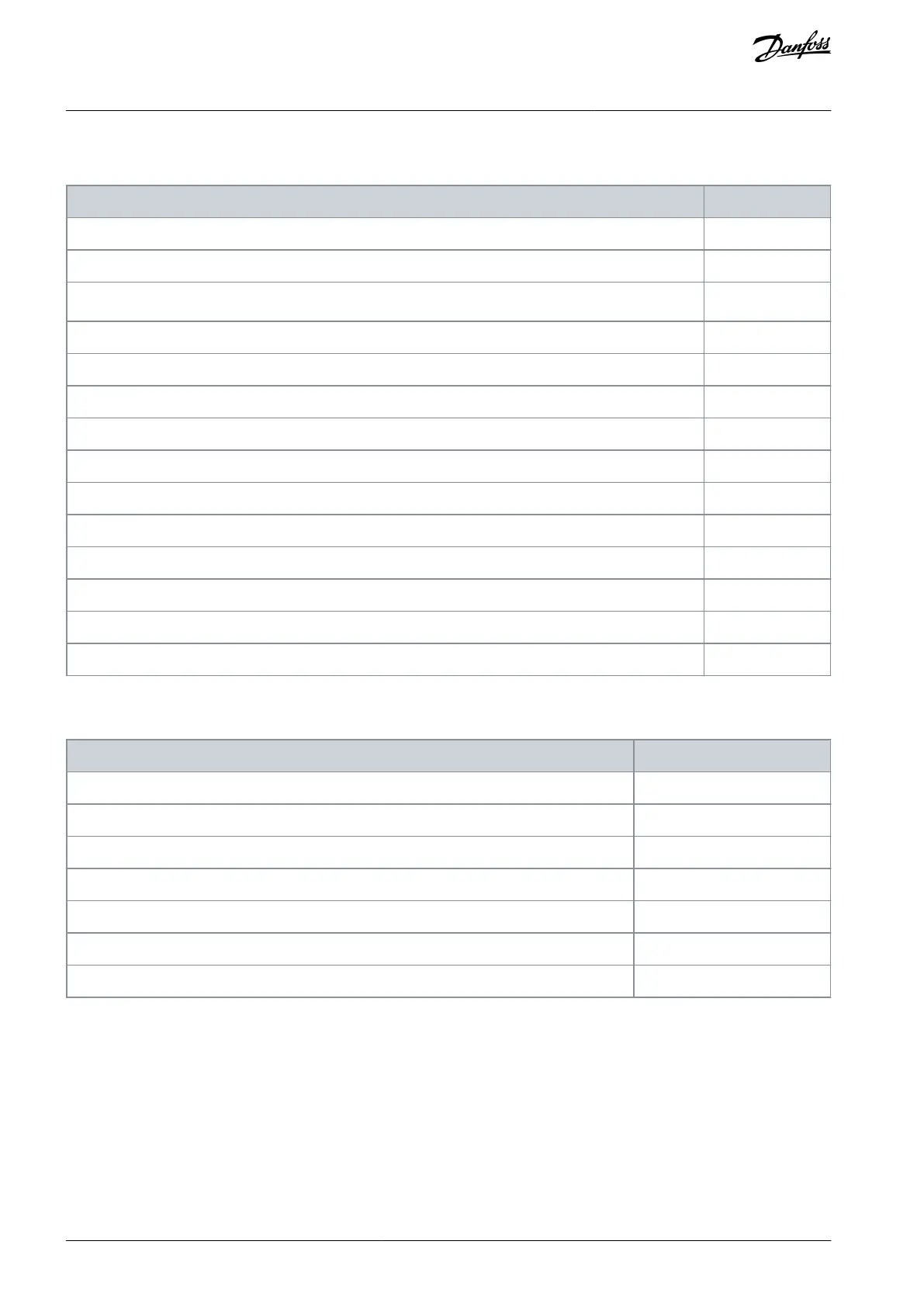

13.2.8 Order Numbers for PC Software

Table 132: Order Numbers for VLT® Motion Control Tool MCT 10

VLT® Motion Control Tool MCT 10, 1 license

VLT® Motion Control Tool MCT 10, 5 licenses

VLT® Motion Control Tool MCT 10, 10 licenses

VLT® Motion Control Tool MCT 10, 25 licenses

VLT® Motion Control Tool MCT 10, 50 licenses

VLT® Motion Control Tool MCT 10, 100 licenses

VLT® Motion Control Tool MCT 10, >100 licenses

13.2.9 Ordering of VLT® Brake Resistors MCE 101

Explanation of terms used in the tables for ordering brake resistors

Horizontal braking: Duty cycle 10% and maximum 120 s repetition rates according to the reference brake prole. Average power

corresponds to 6%.

Vertical braking: Duty cycle 40% and maximum 120 s repetition rates according to the reference brake prole. Average power corre-

sponds to 27%.

Cable cross-section: Recommended minimum value based on PVC-insulated copper cable, 30 °C (86 °F) ambient temperature with

normal heat dissipation. All cabling must comply with national and local regulations on cable cross-sections and ambient tempera-

ture.

Thermal relay: Brake current setting of external thermal relay. All resistors have a built-in thermal relay switch N.C.

AJ300847815559en-000101 / 130R0337184 | Danfoss A/S © 2020.09

How to Order a Drive

VLT® AQUA Drive FC 202

Design Guide

Loading...

Loading...