Installation

XPR300 Instruction Manual 809480 125

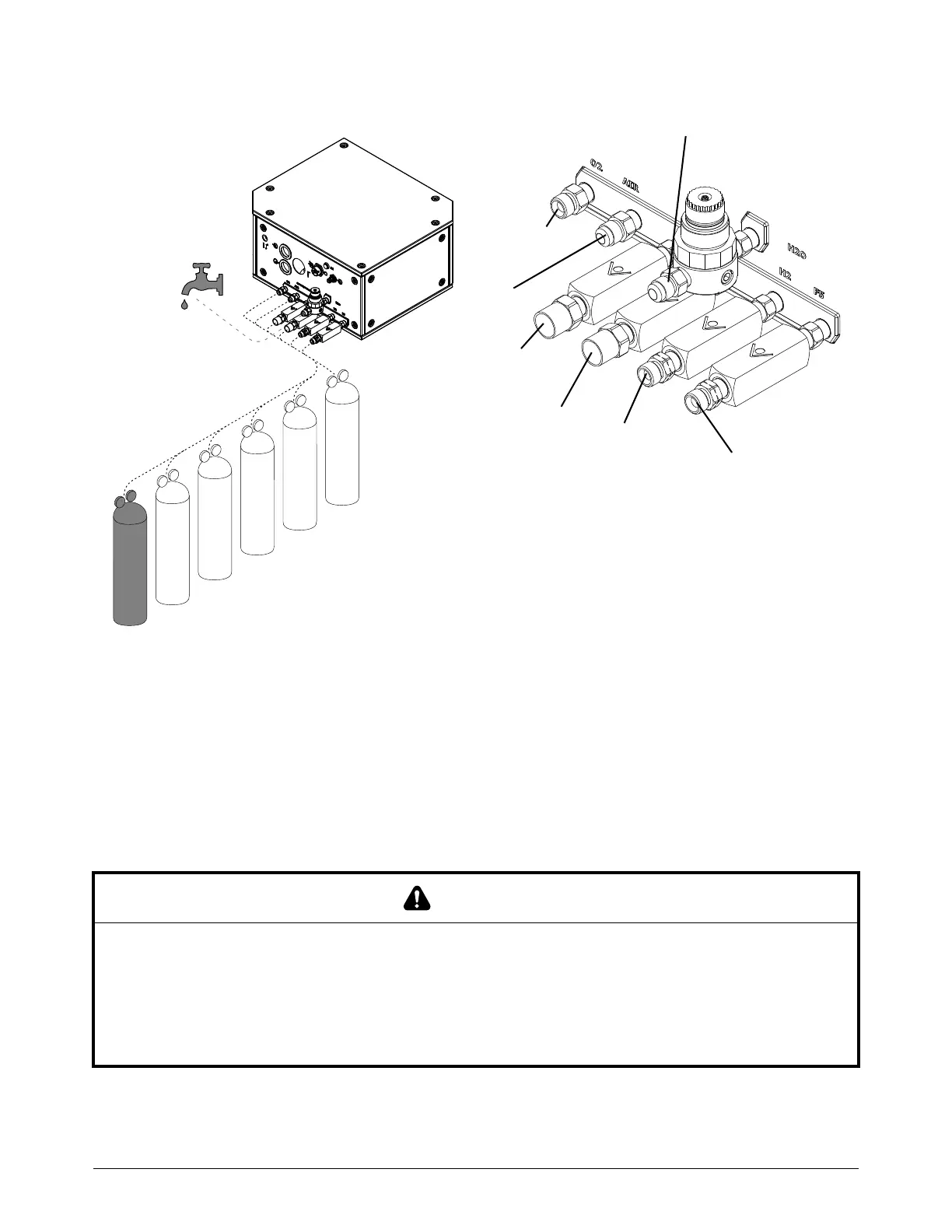

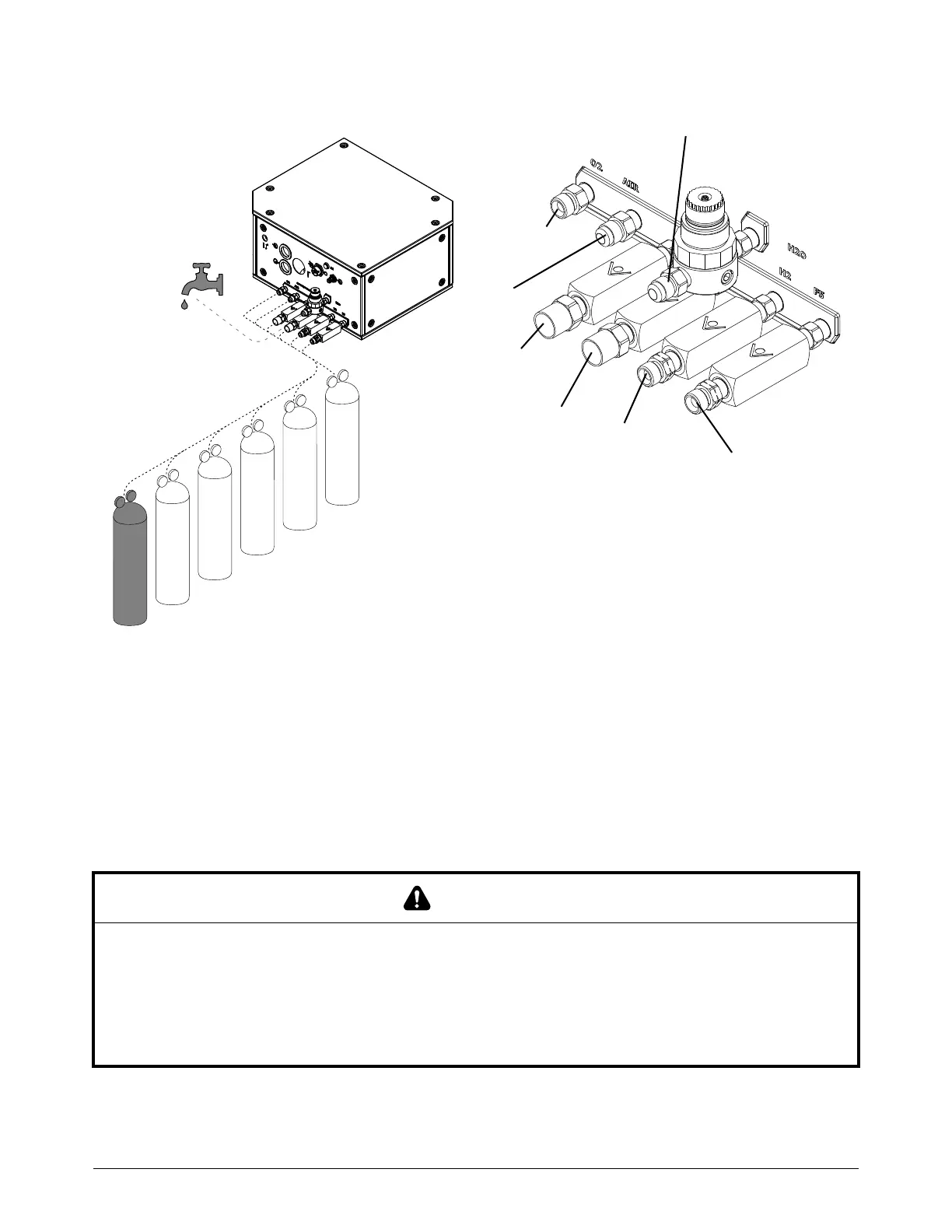

Figure 32 – Connect the supply gas plumbing, gases, and optional shield water to the VWI or OptiMix gas connect

console

* For the best results, make sure that the cutting system is ready for use and the gases are flowing when you

select gas regulator settings, similar to testing gas preflow and cutflow.

1. Make sure that you have the correct supply gas hoses before you connect them. Hypertherm

recommends an internal diameter of at least 10 mm (0.375 inch) for supply-gas hoses that are

76 m (250 feet) or less.

2. Tighten all fittings to the torque specifications in Table 19 on page 118.

3. After installation is complete, pressurize the entire system and look for gas leaks. A licensed

plumber can do this for you.

Hydrogen (H

2

) only for OptiMix

Shield water (H

2

O)

Oxygen (O

2

)

Air

Nitrogen (N

2

)

Argon (Ar)

Hydrogen (H

2

)

F5

Regulators*

Shield water (H

2

O)

only for VWI and

OptiMix

F5

Argon (Ar)

Nitrogen (N

2

)

Air

Oxygen (O

2

)

CAUTION

INCORRECT SUPPLY-GAS CONNECTIONS CAN CAUSE BAD PERFORMANCE

Cutting system performance can be bad if a supply-gas hose is connected to the wrong port on a gas

connect console.

NEVER connect a supply gas to a hose, connection, or fitting that is not designed for that gas type or

pressure.

Loading...

Loading...