Qualifications and Requirements

46 809480 Instruction Manual XPR300

Process gas requirements (Core, VWI, and OptiMix gas connect consoles)

As an installer or user, you must supply the process gases and supply gas plumbing for your cutting

system. Refer to Table 7 on page 46 for supply gas quality, pressure, and flow requirements.

Process gas requirements include the following:

Nitrogen is required for all processes.

Air is required for H

2

mix processes.

Water can be used as a shield fluid for plasma power supplies that have a VWI or OptiMix

gas connect console. Refer to Shield water requirements (VWI and OptiMix) on page 51 for

the specifications and requirements for water that is used for shield purposes.

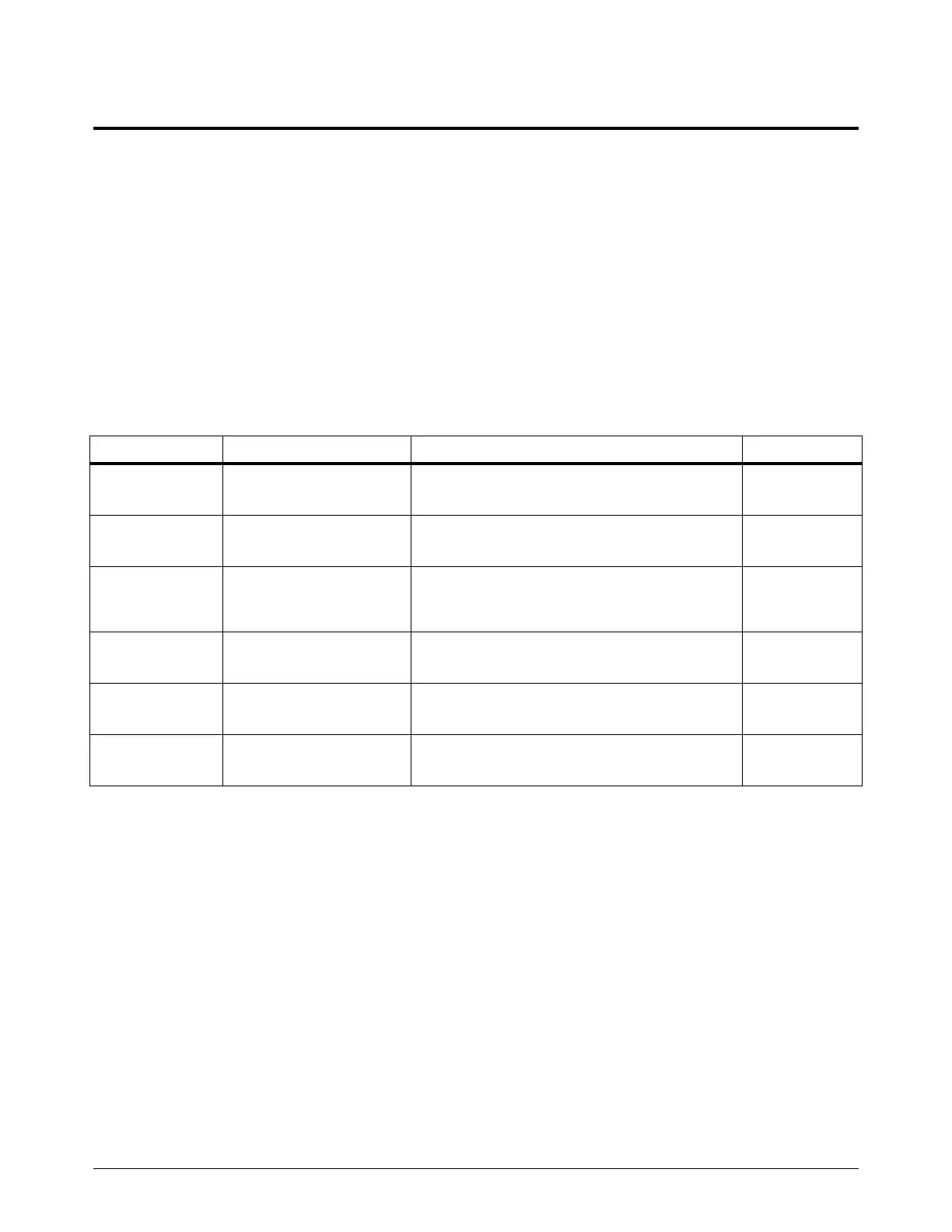

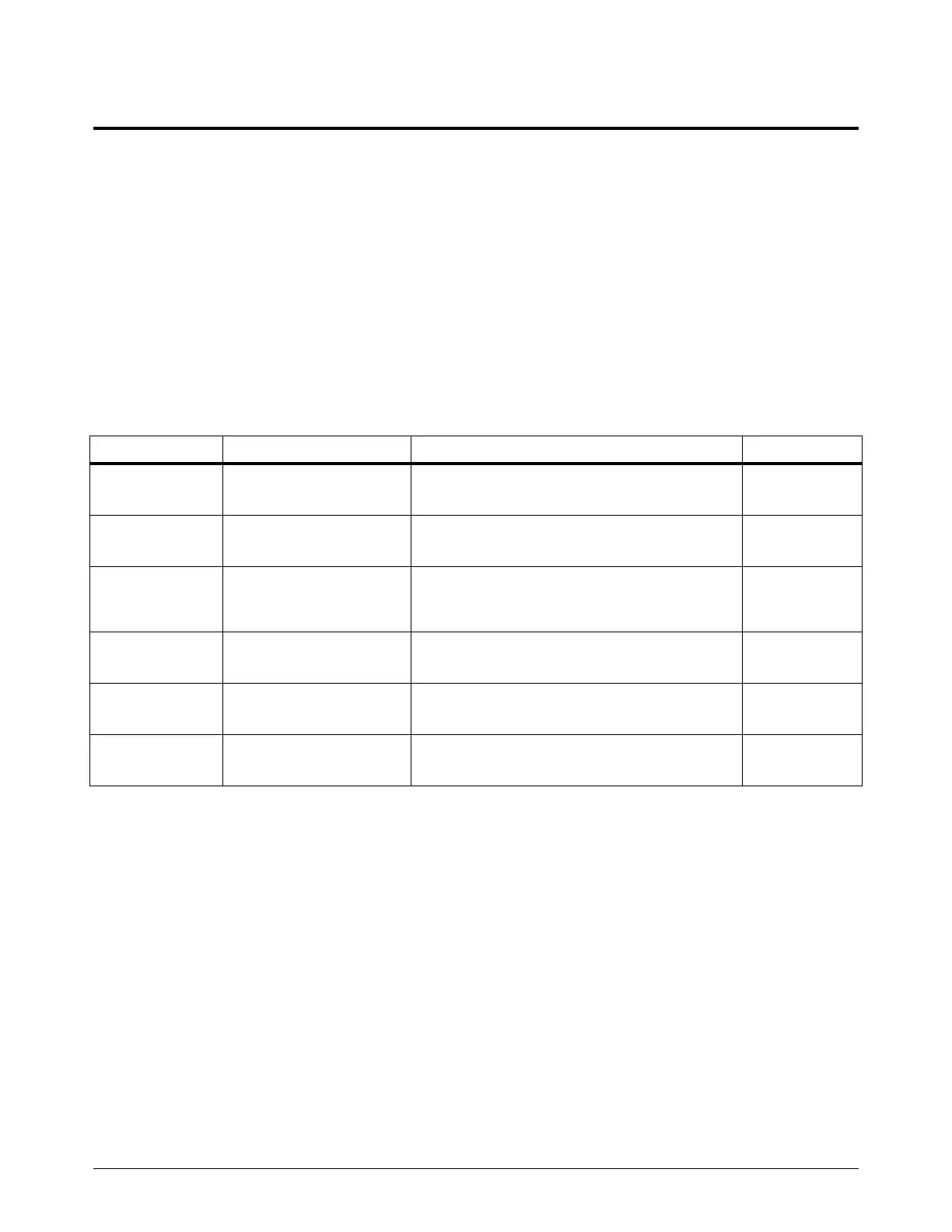

Table 7 – Gas quality, pressure, and flow requirements

* When there is no gas flow, make sure that the pressure at the gas inlet connection is less than 8.6 bar

(125 psi) to avoid system alerts.

** Any air compressors that supply air to the cutting system must remove oil prior to air delivery.

Gas Quality System inlet pressure (during gas flow*) Flow rate

O

2

(oxygen) 99.5% pure, clean, dry,

oil-free

Core, VWI: 7.5 bar ± 0.4 (110 psi ± 5)

OptiMix: 7.9 bar ± 0.4 (115 psi ± 5)

71 slpm

(150 scfh)

N

2

(nitrogen) 99.99% pure, clean, dry,

oil-free

Core, VWI: 7.5 bar ± 0.4 (110 psi ± 5)

OptiMix: 8.3 bar ± 0.4 (120 psi ± 5)

181 slpm

(380 scfh)

Air** Clean, dry, oil free

consistent with

8573-1:2010 Class 1.4.2

Core, VWI: 7.5 bar ± 0.4 (110 psi ± 5)

OptiMix: 7.9 bar ± 0.4 (115 psi ± 5)

118 slpm

(250 scfh)

H

2

(hydrogen) 99.995% pure

OptiMix: 8.3 bar ± 0.4 (120 psi ± 5)

50 slpm

(105 scfh)

Ar (argon) 99.99% pure; clean, dry,

oil-free

VWI: 7.5 bar ± 0.4 (110 psi ± 5)

OptiMix: 8.3 bar ± 0.4 (120 psi ± 5)

118 slpm

(250 scfh)

F5 (95% nitrogen,

5% hydrogen)

99.98% pure VWI: 7.5 bar ± 0.4 (110 psi ± 5)

OptiMix: 7.9 bar ± 0.4 (115 psi ± 5)

40 slpm

(85 scfh)

Hypertherm recommends that air compressors supply air that obey the following requirements of ISO

Standard 8573-1:2010 Class 1.4.2:

Maximum particle count in 1.0 m

3

: • 20,000 at 0.1 microns – 0.5 microns

• 400 at 0.5 microns – 1.0 microns

• 10 at 1.0 microns – 5.0 microns

Maximum water vapor pressure dew point: 3°C (37°F)

Maximum oil concentration: 0.1 mg/m

3

(for aerosol, liquid, and vapor)

Speak to your air compressor manufacturer if you operate the cutting system in

temperatures colder than 3°C (37°F) or if you are unsure that the air compressor

can obey the ISO standard for air quality.

Loading...

Loading...