Connect for Communication

XPR300 Instruction Manual 809480 193

How to use ohmic contact sense

Ohmic relay overview

The relay is normally open when not powered.

The relay is closed during operation, except during ignition or cutting with water processes.

Ohmic contact is disabled when cutting with a water process.

Ohmic contact is disabled when the remote on-off switch is in the OFF position.

Internal ohmic contact sense

This is the default installation for the torch and torch connect console. No action is required.

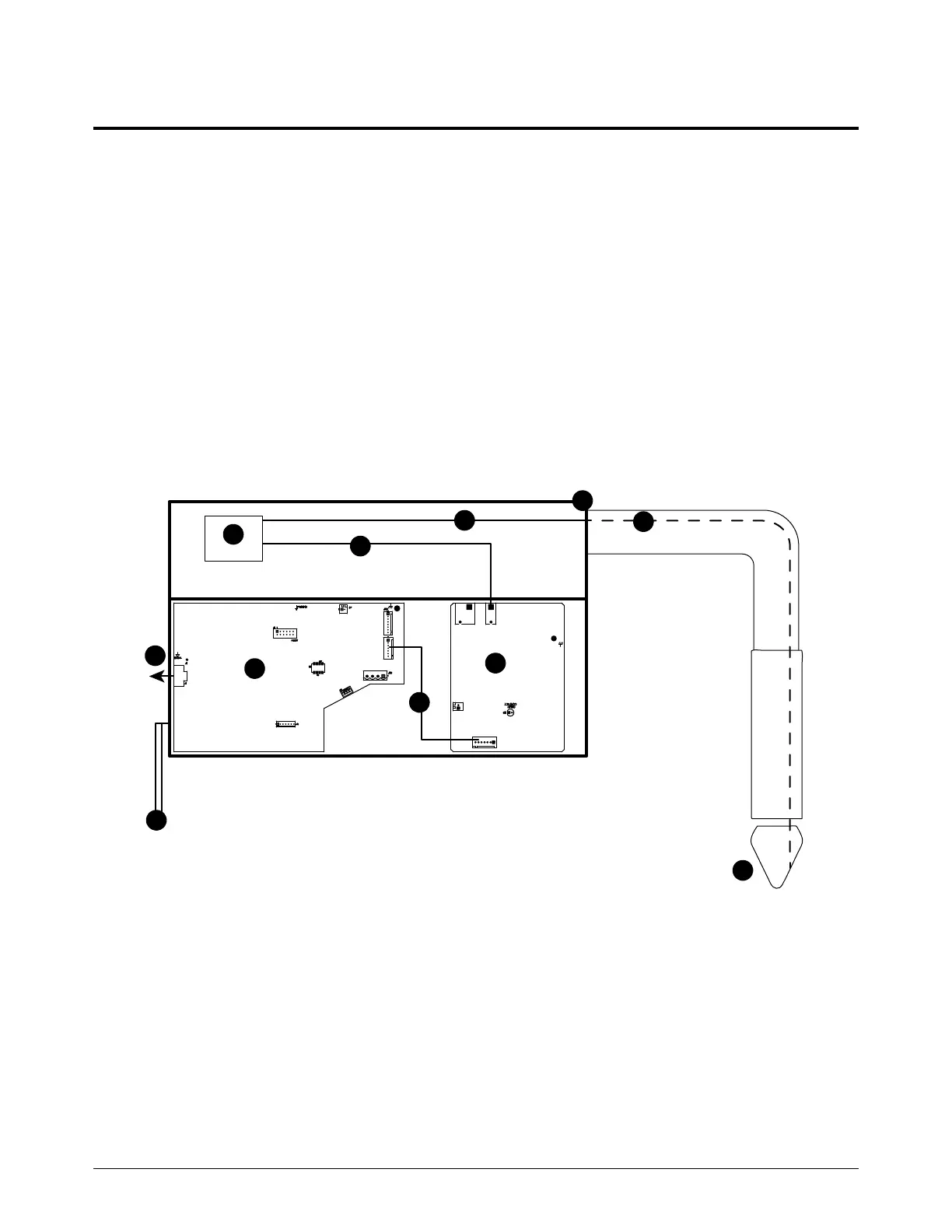

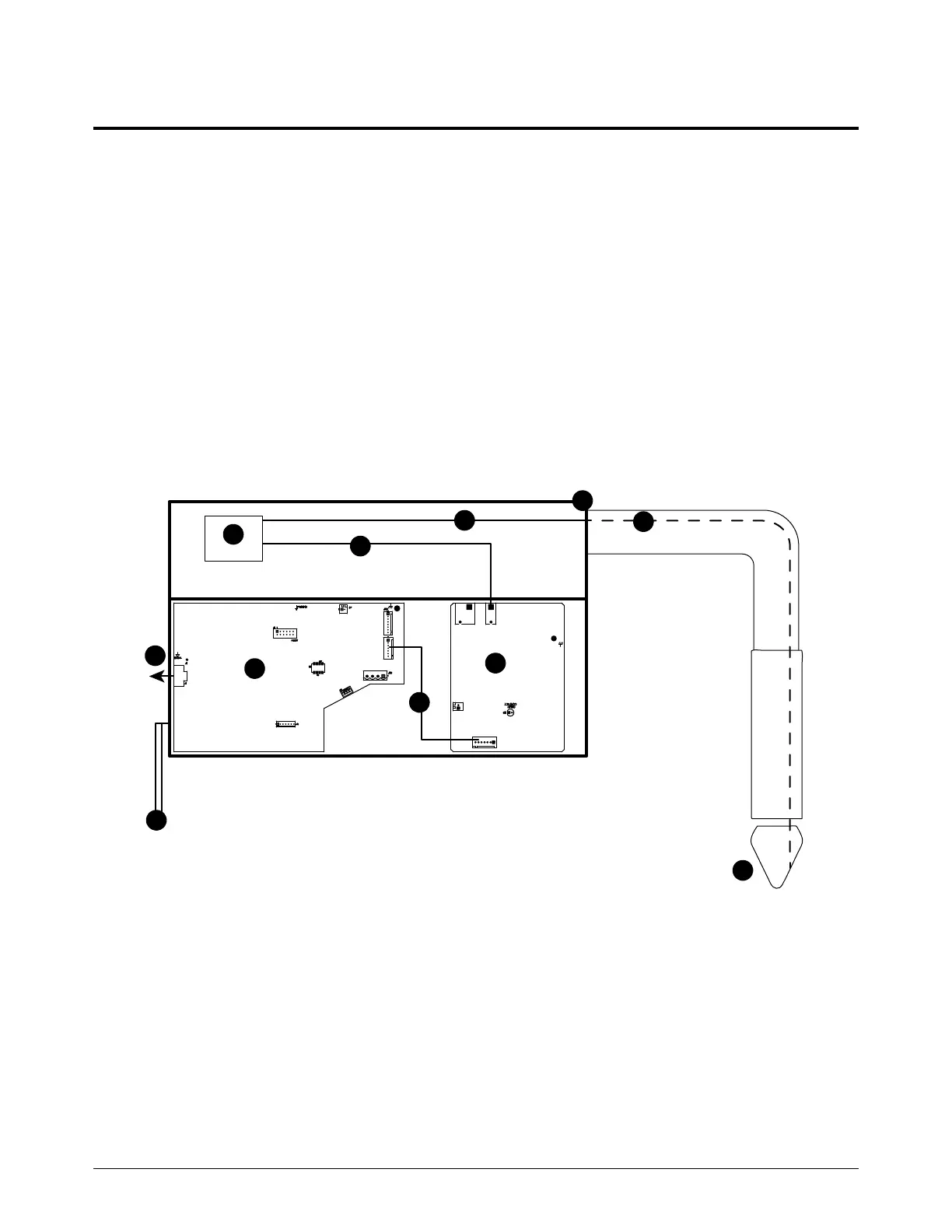

Figure 53 – Internal ohmic diagram

1 Torch

2 Ohmic wire, inside torch and torch lead

3 Torch connect console

4 Ohmic wire, torch receptacle to ohmic relay

5 Ohmic relay

6 Ohmic wire, ohmic relay to J3

7 Ohmic PCB

8 J1 to J27 wires

9 Control PCB

10 CAN connection

11 2 ground connections (required)

Loading...

Loading...